Compact electric cam phaser

A cam and camshaft technology, applied to engine components, machines/engines, valve devices, etc., can solve the problem that the engine oil pressure cannot fully supply the power of the hydraulic drive cam phaser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following detailed description serves to explain the invention by way of example, not to limit the invention. This description enables one of ordinary skill in the art to make and use the disclosure, and describes various embodiments, improvements, variations, alternatives and uses of the disclosure, including what is presently believed to be the best mode of the disclosure.

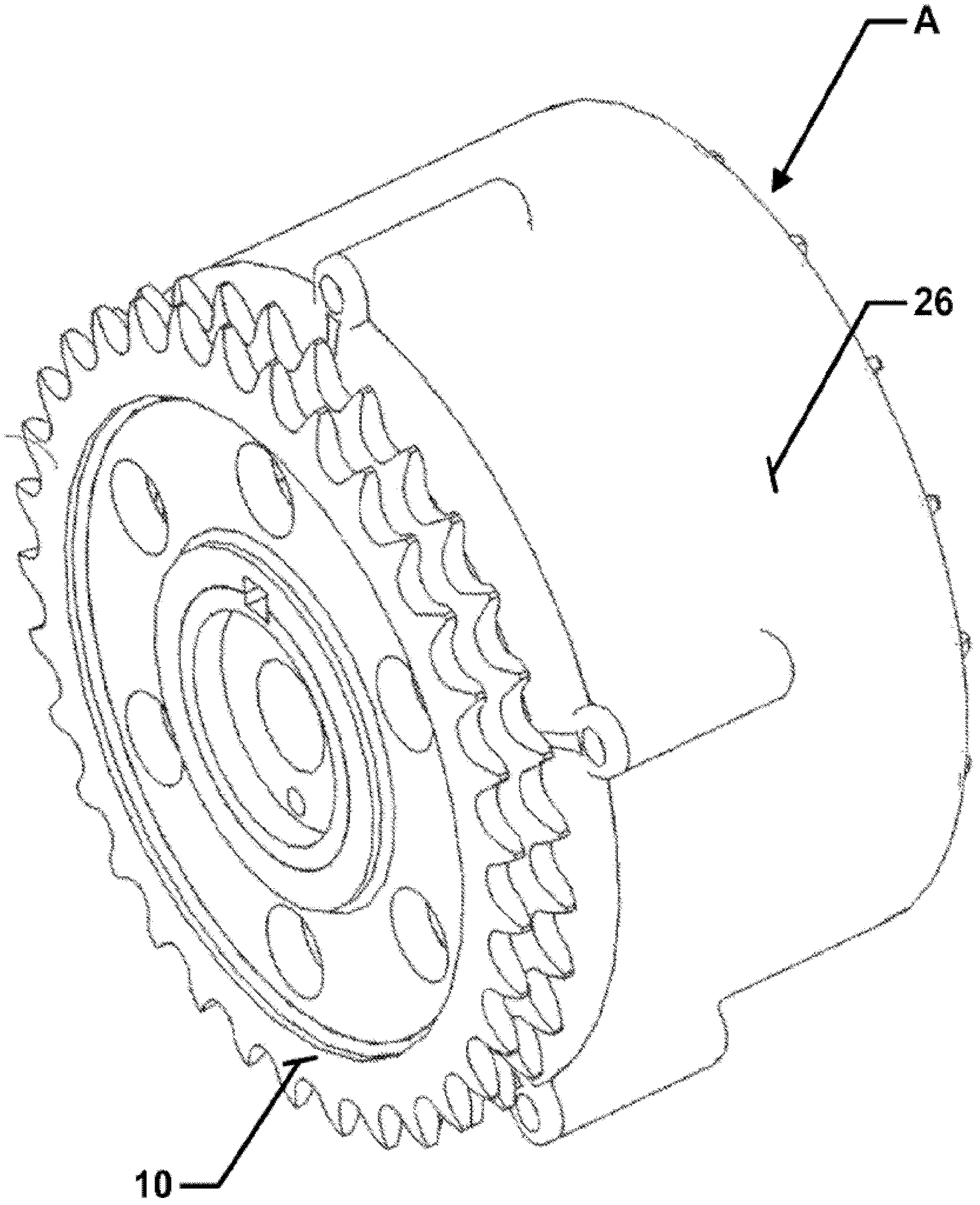

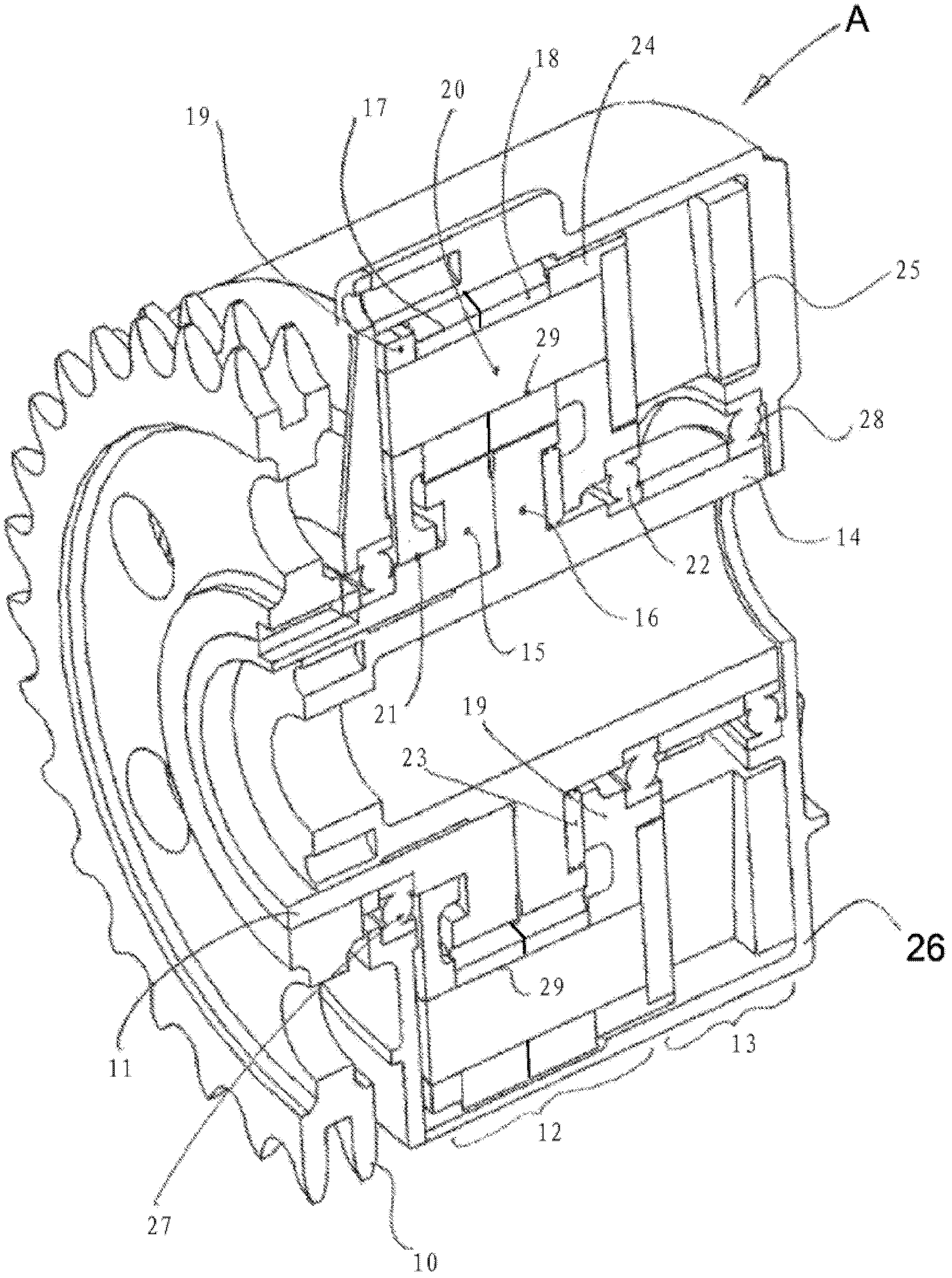

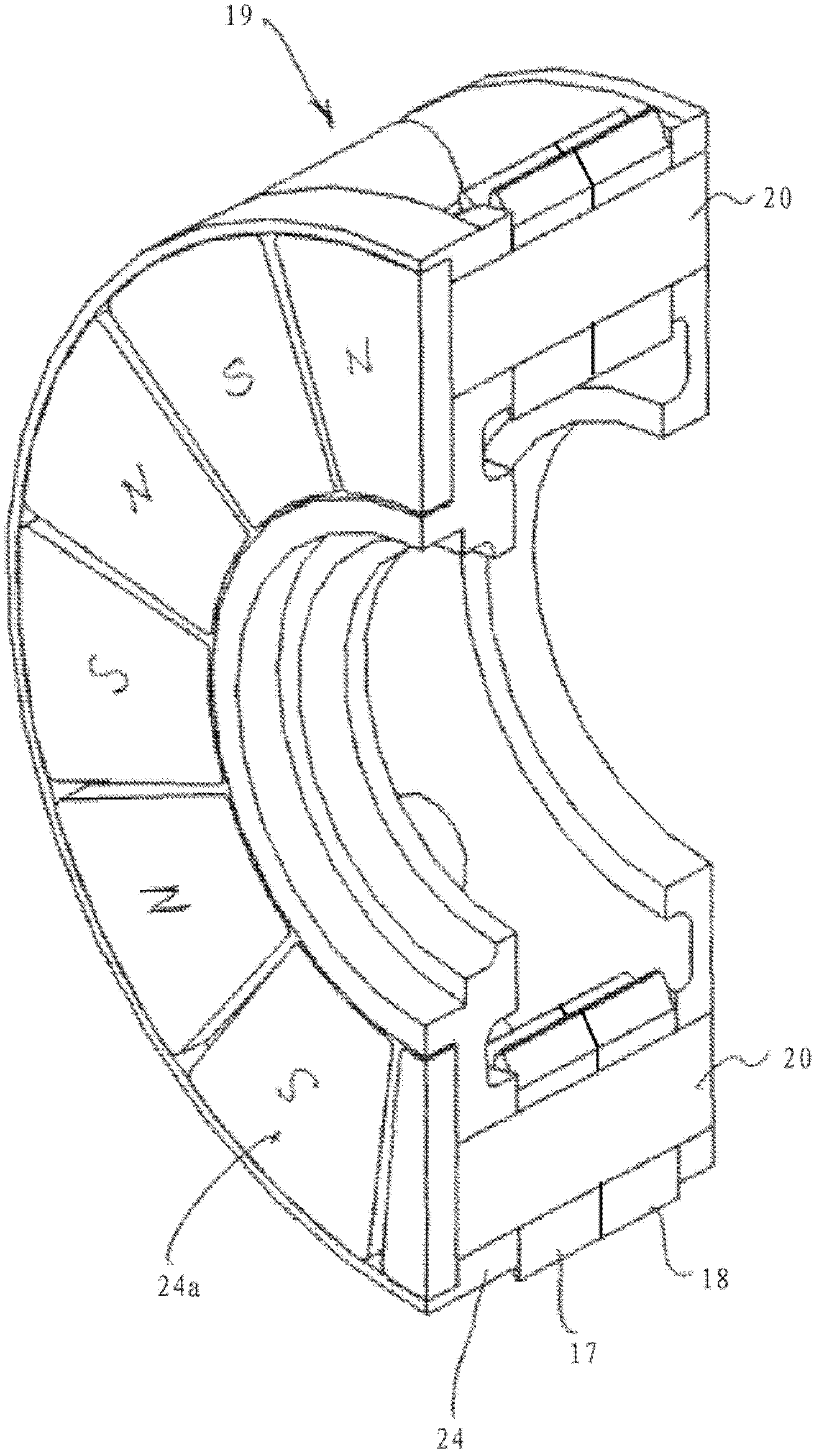

[0022] Look back at the pictures, especially figure 1 and figure 2 , the electric cam phaser as a whole is represented by A, which includes a sprocket 10, an input shaft 11, a differential gear train 12, an axial flux motor 13 arranged axially adjacent to the differential gear train 12, and an output shaft 14. The differential gear train 12 and the axial flux motor 13 are housed within a housing 26 .

[0023] The differential gear train 12 further includes an input sun gear 15 connected to the input shaft 11 , an output sun gear 16 connected to the output shaft 14 , a first set of planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com