Mosquito-repellent incense with residue obtained after volatile oil extraction from typus physiologions cinnanloni leaf as base material and production method thereof

The technology of plum leaves and volatile oil is applied in the field of mosquito coils based on the residue after extracting volatile oil from plum leaves, and the production field thereof, which can solve the problems of limited content, toxic and side effects, irritating effects and the like, and achieves fragrant smell and mosquito repellent effects. Good, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Mosquito incense based on residues of volatile oil extracted from plum leaves and production method thereof

[0011] Dissolve 4 g of the perfume in water, the mass volume ratio of the perfume to the water is 1:6, and prepare the perfume solution. Pour 1 / 3 of the spice solution into 15g of corn starch and stir for 30 minutes, then pour in the remaining spice solution, stir evenly, and heat at 70°C while stirring until the starch is gelatinized. After extracting volatile oil from plum leaves, 20 g of residue powder, 15 g of charcoal powder, 15 g of wood powder, and 10 g of root stick powder are thoroughly mixed with gelatinized starch to obtain a viscous paste. The viscous paste obtained above is placed in an incense making machine for molding, and then dried in an oven at 60°C to obtain a finished mosquito coil.

Embodiment 2

[0013] Mosquito coils based on residues of volatile oil extracted from plum leaves and production method thereof

[0014] Dissolve 4.5 g of the fragrance in water, and the mass volume ratio of the fragrance to the water is 1:8 to prepare a fragrance solution. Pour 1 / 3 of the spice solution into 18g of corn starch and stir for 35 minutes, then pour in the remaining spice solution, stir evenly, and heat at 80°C while stirring until the starch is gelatinized. After extracting volatile oil from plum leaves, 22 g of residue powder, 18 g of charcoal powder, 18 g of wood powder, and 15 g of root stick powder are thoroughly mixed with gelatinized starch to obtain a viscous paste. The viscous paste obtained above is put into an incense making machine for molding, and then dried in an oven at 70° C. to obtain a finished mosquito coil.

Embodiment 3

[0016] Mosquito coils based on residues of volatile oil extracted from plum leaves and production method thereof

[0017] Dissolve 5 g of the fragrance in water, and the mass volume ratio of the fragrance to the water is 1:10 to prepare a fragrance solution. Pour 1 / 3 of the spice solution into 20g of corn starch and stir for 40 minutes, then pour the remaining spice solution, stir evenly, and heat at 85°C while stirring until the starch is gelatinized. After extracting the volatile oil from the plum leaves, 25 g of residue powder, 20 g of charcoal powder, 20 g of wood powder, and 20 g of root stick powder are thoroughly mixed with gelatinized starch to obtain a viscous paste. The viscous paste obtained above is placed in an incense making machine for molding, and then dried in an oven at 80°C to obtain a finished mosquito coil.

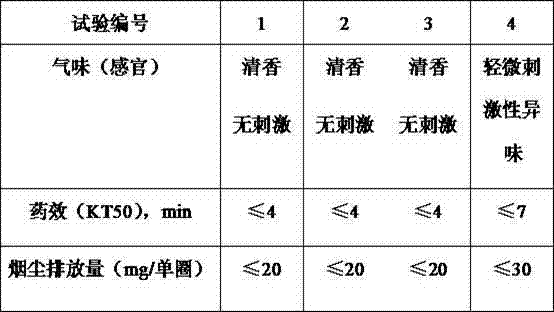

[0018] The method for testing the burning mosquito coil prepared by the above process is as follows:

[0019] (1) Odor inspection: sensory, no irritating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com