Treatment process of dry method or semi-dry method smoke gas desulfurized slag

A treatment process and desulfurization slag technology, applied in the field of solid waste treatment, can solve the problems of limited product value, inability to commercialize the technology, high cost, etc., and achieve the effect of low cost, mature equipment and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

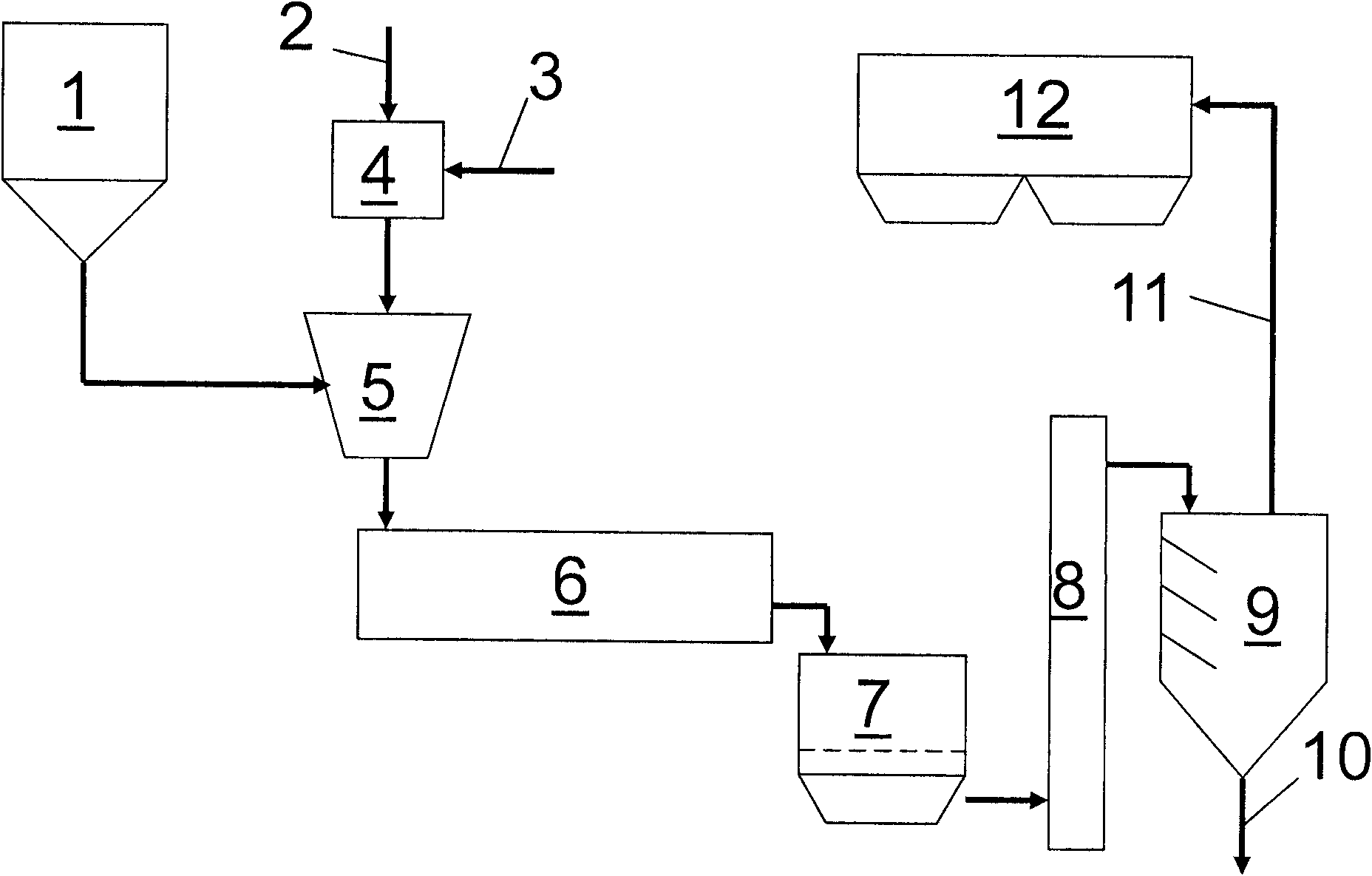

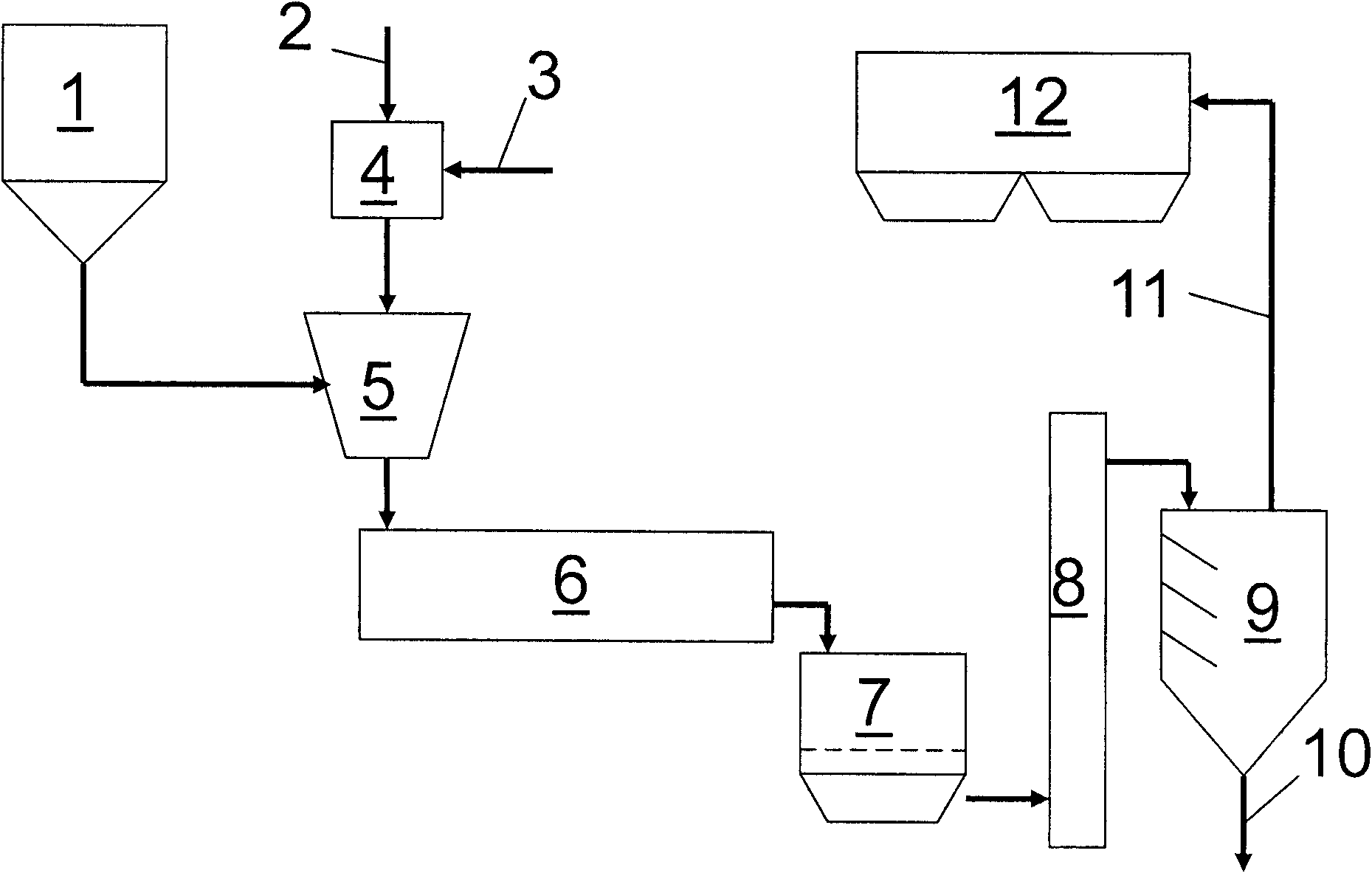

Method used

Image

Examples

Embodiment 1

[0032] Example 1: 90 tons of desulfurization slag is processed every day, and 270 tons of liquid steel slag is added every day. Desulfurization slag and liquid steel slag are added in batches, 6 tons of desulfurization slag are added in each batch, and 18 tons of liquid steel slag are added at the same time. The ratio of steel slag particles to desulfurization slag is 3:1. The time from entering the kiln to leaving the kiln for the mixed material is about 75 minutes, of which the reaction in the kiln is 50 minutes, the temperature of the mixed material leaving the kiln is 320 ° C, and the conversion rate of calcium sulfite is 80%.

Embodiment 2

[0033] Example 2: 60 tons of desulfurization slag are processed every day, and 240 tons of liquid steel slag is added every day. Desulfurization slag and liquid steel slag are added in batches, 5 tons of desulfurization slag are added in each batch, and 20 tons of liquid steel slag are added at the same time. The ratio of steel slag particles to desulfurization slag is 3:1. The time from entering the kiln to leaving the kiln for the mixed material is about 65 minutes, of which the reaction in the kiln is 40 minutes, the temperature of the mixed material leaving the kiln is 380 ° C, and the conversion rate of calcium sulfite is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com