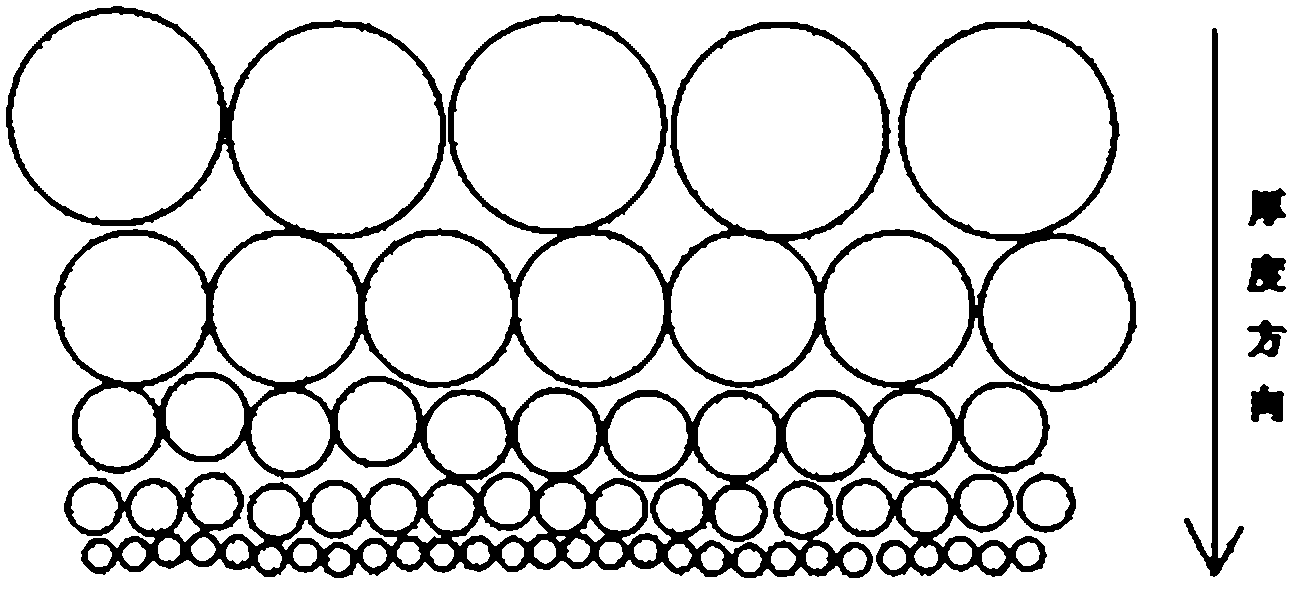

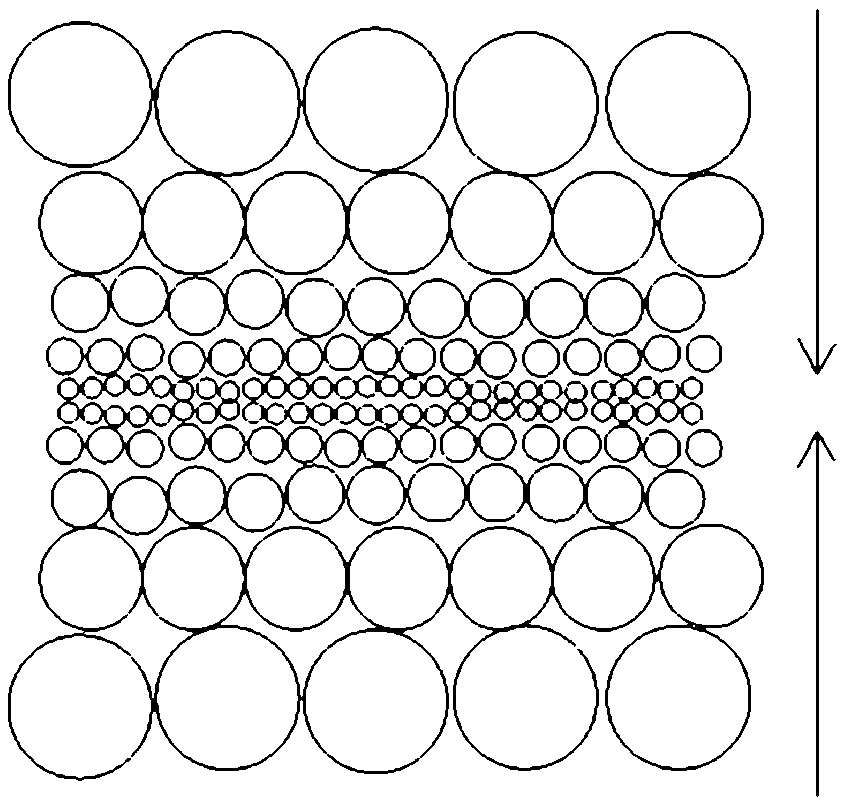

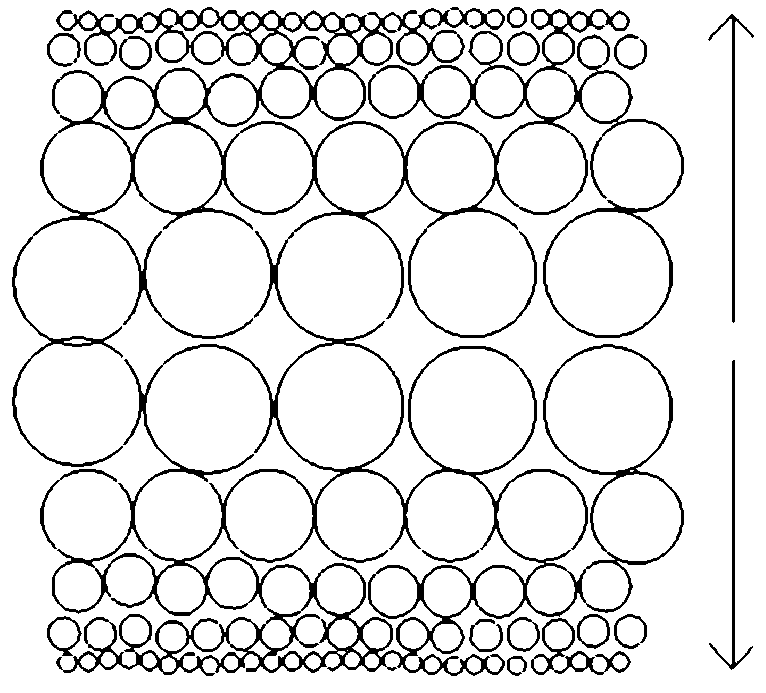

Polymeric foam composite material having gradient structure and preparing method thereof

A composite material and gradient structure technology, applied in the field of foam composite materials, to achieve the effect of environmental protection and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, polystyrene (PS) and polymethyl methacrylate (PMMA) are used as raw materials, polystyrene and polymethyl methacrylate are amorphous thermoplastic polymers, and polystyrene (PS) is produced by Taihua Produced by Plastic Co., Ltd., model 5250A230, density 1.04g / cm 3 , Polymethyl methacrylate is produced by Sumitomo Chemical Company, model LG2, density is 1.19g / cm 3 . The process steps are as follows:

[0032] (1) Preparation of the blend

[0033] According to the mass ratio batching of polystyrene (PS) and polymethyl methacrylate (PMMA), measure out PS: PMMA=90: 10, PS: PMMA=60: 40 two kinds of compositions raw materials, then two kinds of combination The raw materials of the compound were premixed at normal pressure and room temperature respectively, and mixed in a torque rheometer at normal pressure and 200°C for 6 minutes to obtain two blends of PS and PMMA with different mass ratios.

[0034] (2) Preparation of composite body

[0035] The ble...

Embodiment 2

[0040] The raw material of present embodiment is identical with embodiment 1, and processing step is as follows:

[0041] (1) Preparation of the blend

[0042] According to the mass ratio batching of polystyrene (PS) and polymethyl methacrylate (PMMA), measure out PS: PMMA=90: 10, PS: PMMA=50: 50 two kinds of compositions raw materials, then two kinds of combination The raw materials of the compound were premixed at normal pressure and room temperature respectively, and mixed in a torque rheometer at normal pressure and 200°C for 6 minutes to obtain two blends of PS and PMMA with different mass ratios.

[0043] (2) Preparation of composite body

[0044]The blends of two different mass ratios of PS and PMMA prepared in step (1) are respectively vacuum-pressed and molded, and after cooling and shaping with tap water, two sheet compositions having a thickness of 1 mm with different mass ratios of PS and PMMA are obtained , and then two sheets of PS:PMMA=90:10 sheet composition ...

Embodiment 3

[0049] This embodiment takes polystyrene (PS), polymethyl methacrylate (PMMA) and acrylonitrile-styrene copolymer (SAN) as raw materials, polystyrene, polymethyl methacrylate and acrylonitrile-styrene Copolymer is an amorphous thermoplastic polymer, and the production enterprise, model and density of polystyrene (PS) and polymethyl methacrylate (PMMA) are identical with embodiment 1, and acrylonitrile-styrene copolymer (SAN) is made of Produced by Lanzhou Petrochemical Company, model BHF, density 1.05g / cm 3 . The process steps are as follows:

[0050] (1) Preparation of the blend

[0051] According to the mass ratio batching of polystyrene (PS) and acrylonitrile-styrene copolymer (SAN) and polymethyl methacrylate (PMMA) and acrylonitrile-styrene copolymer (SAN), measure out PS: SAN= 90:10, PMMA:SAN=90:10 two compositions of raw materials, and then the raw materials of the two compositions were premixed at normal pressure and room temperature respectively, and were tested in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com