Sinter grading charging method

A technology of sintering ore and sintering materials, which is applied in the field of blast furnace smelting, can solve the problems of not being able to effectively improve the air permeability of large-scale blast furnace material columns, not being able to adjust the reasonable distribution of gas flow, and being unfavorable for the stable and smooth flow of blast furnaces, etc., so as to improve the utilization rate of gas, Flexible adjustment, control effect of particle size segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

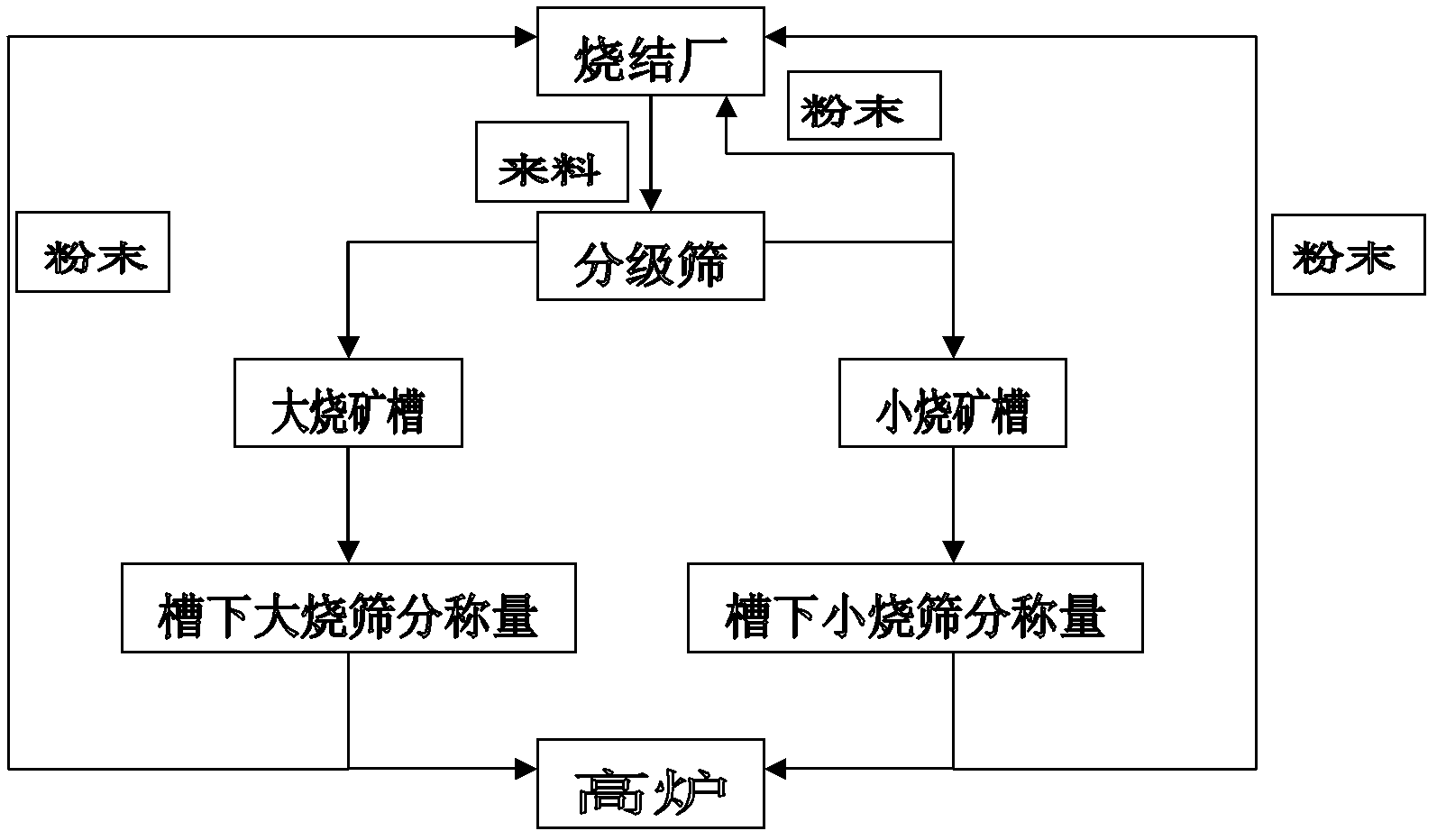

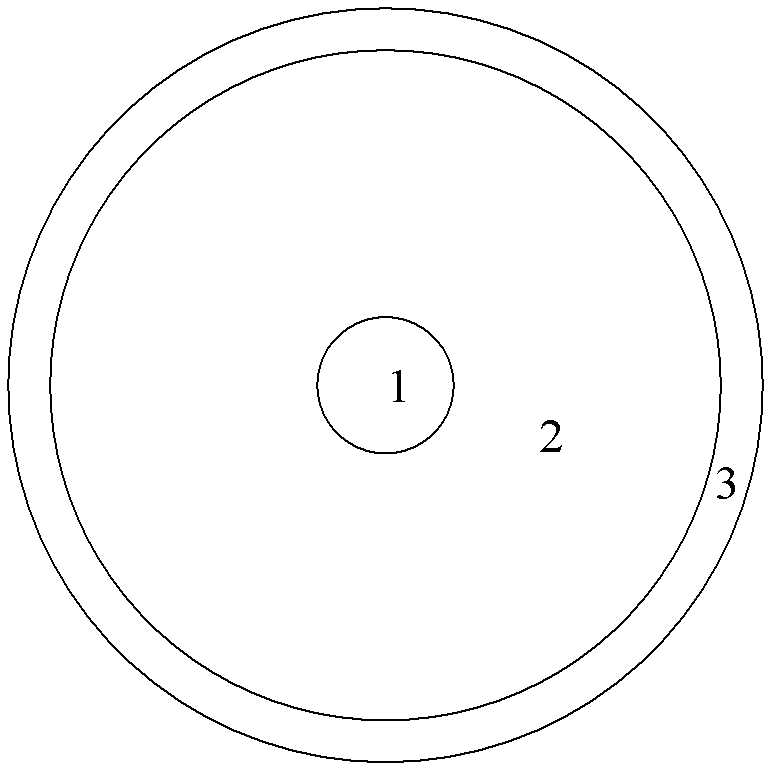

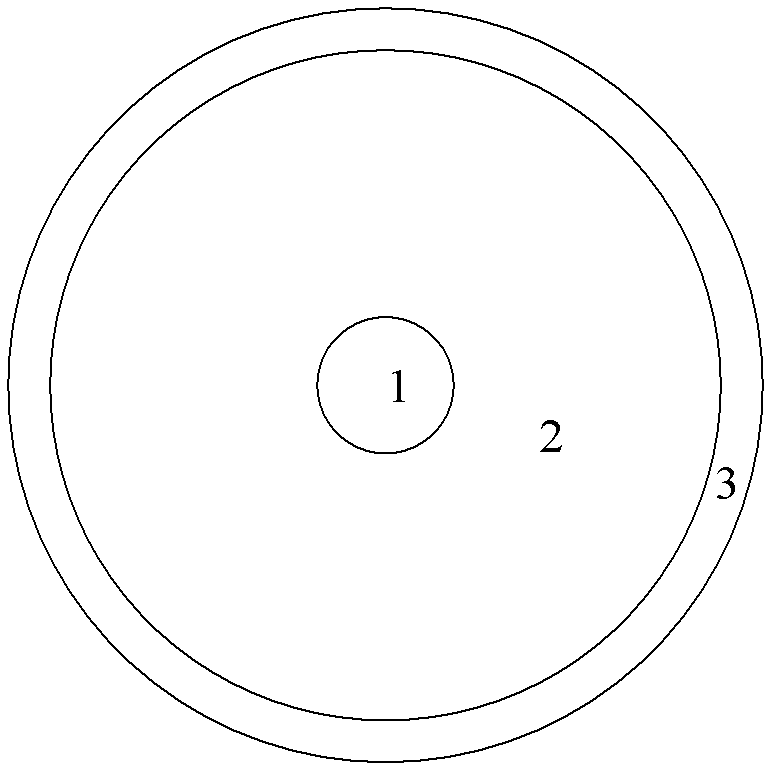

[0015] The sintering method shown in the figure is to classify the incoming materials from the sintering plant through the grading sieve according to the particle size D. The particle size of the primary sintering material is D≥13mm, and the particle size of the secondary sintering material is 4≤D<13mm. , put into the corresponding ore trough after classification, weigh under the ore trough and send it into the blast furnace. The radial periphery of the first-grade sintering material, its proportion is 20% to 25% of the total ore mix in the blast furnace, and the occupied width is 1 / 30 to 1 / 18 of the inner diameter of the furnace, and the particle size D<4mm sintering material is returned as powder To the sintering plant for re-sintering.

[0016] Embodiment: A screening building is set up between the sintering ore transport belt and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com