Manufacture method of instant lotus root starch

A production method and lotus root flour technology, applied in the field of lotus root flour production, can solve the problems of insufficient toughness of lotus root flour, poor brewing effect, and unsatisfactory customers, and achieve good water absorption, long storage time, and fast dissolving speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The lotus root powder is made according to the following steps:

[0017] ① Grind lotus root raw materials into powder through a crusher;

[0018] ② Add white granulated sugar and maltodextrin to the powdered lotus root starch and stir. The weight percentage of the added white granulated sugar and maltodextrin to the original lotus root starch is as follows:

[0019] Lotus root starch 40-50%, white sugar 30-40%, maltodextrin 10-20%,

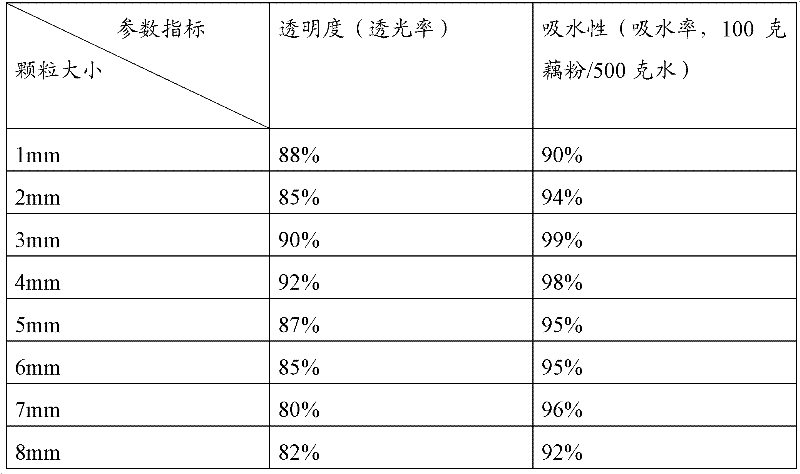

[0020] And made into granules, the size of lotus root starch particles is 3-4mm in diameter;

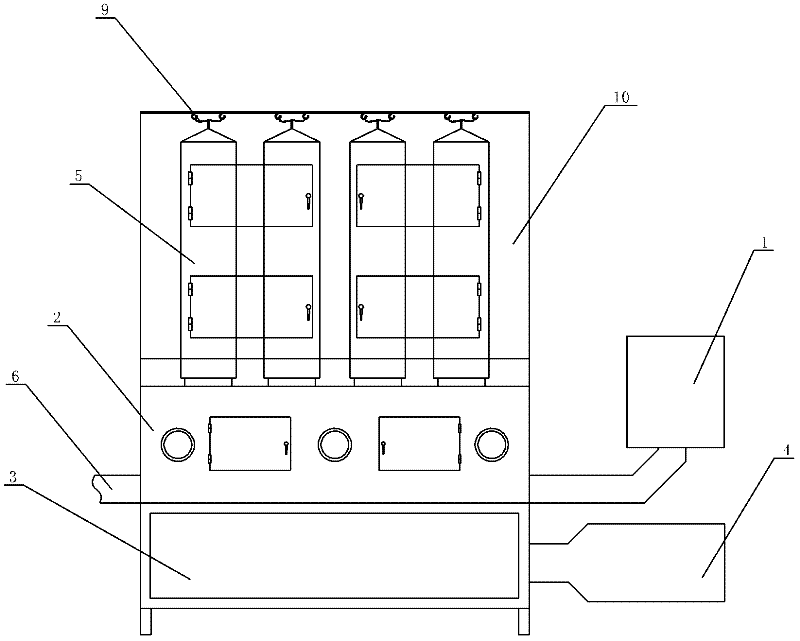

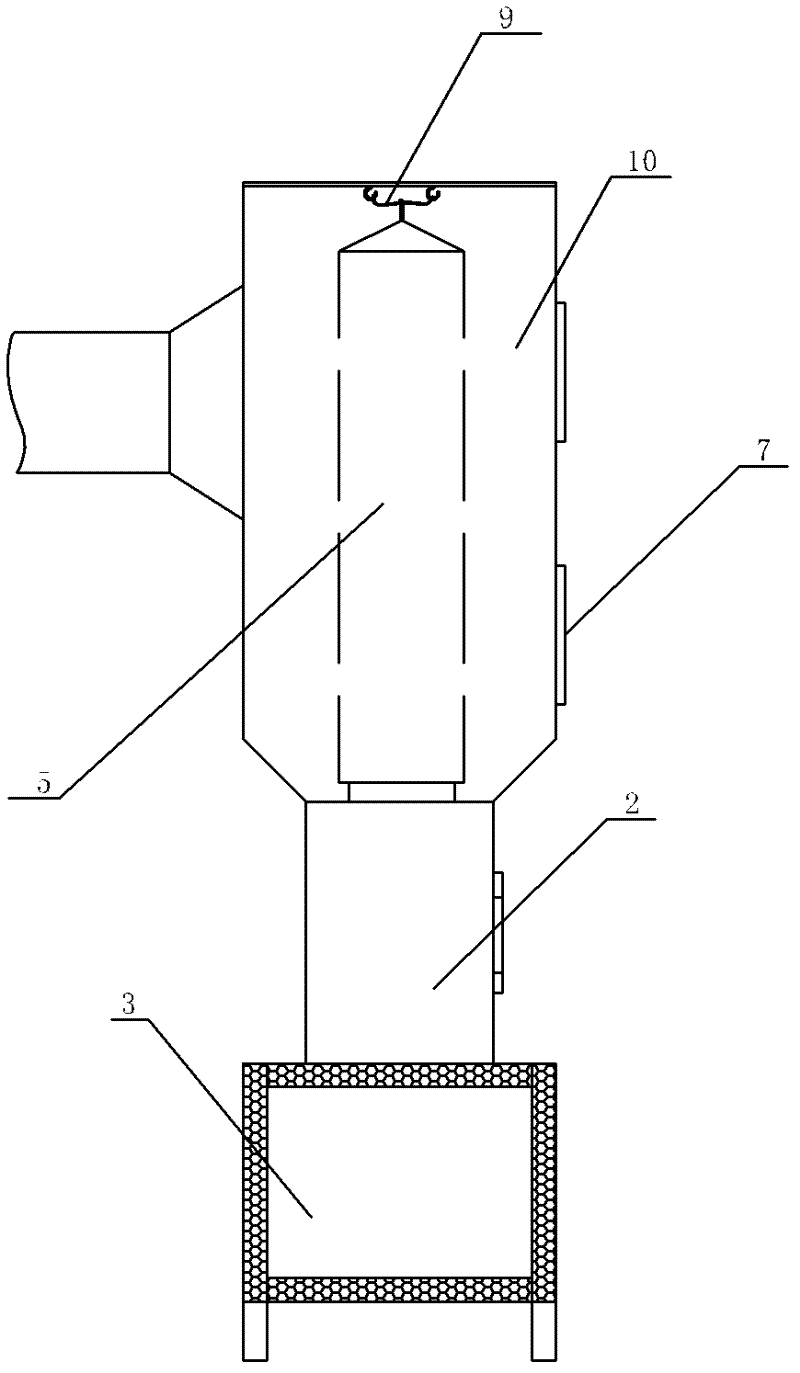

[0021] ③Put the lotus root powder particles into the drying chamber 2 through the feed chamber 1 of the dryer, start the heating chamber 3 to heat the drying chamber 2, and start the blower 4 to blow the lotus root powder particles in the drying chamber 2 to make it Go up and circulate in the cloth bag 5, after a period of heating and drying, close the heating chamber 3 and the blower 4, and the heated and dried lotus root starch particles come ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com