Method for preparing isobutylene by using adsorption separation method

A technology for adsorption separation and isobutene, which is applied in the direction of adsorption purification/separation, etc., which can solve the problems of limited application and low reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

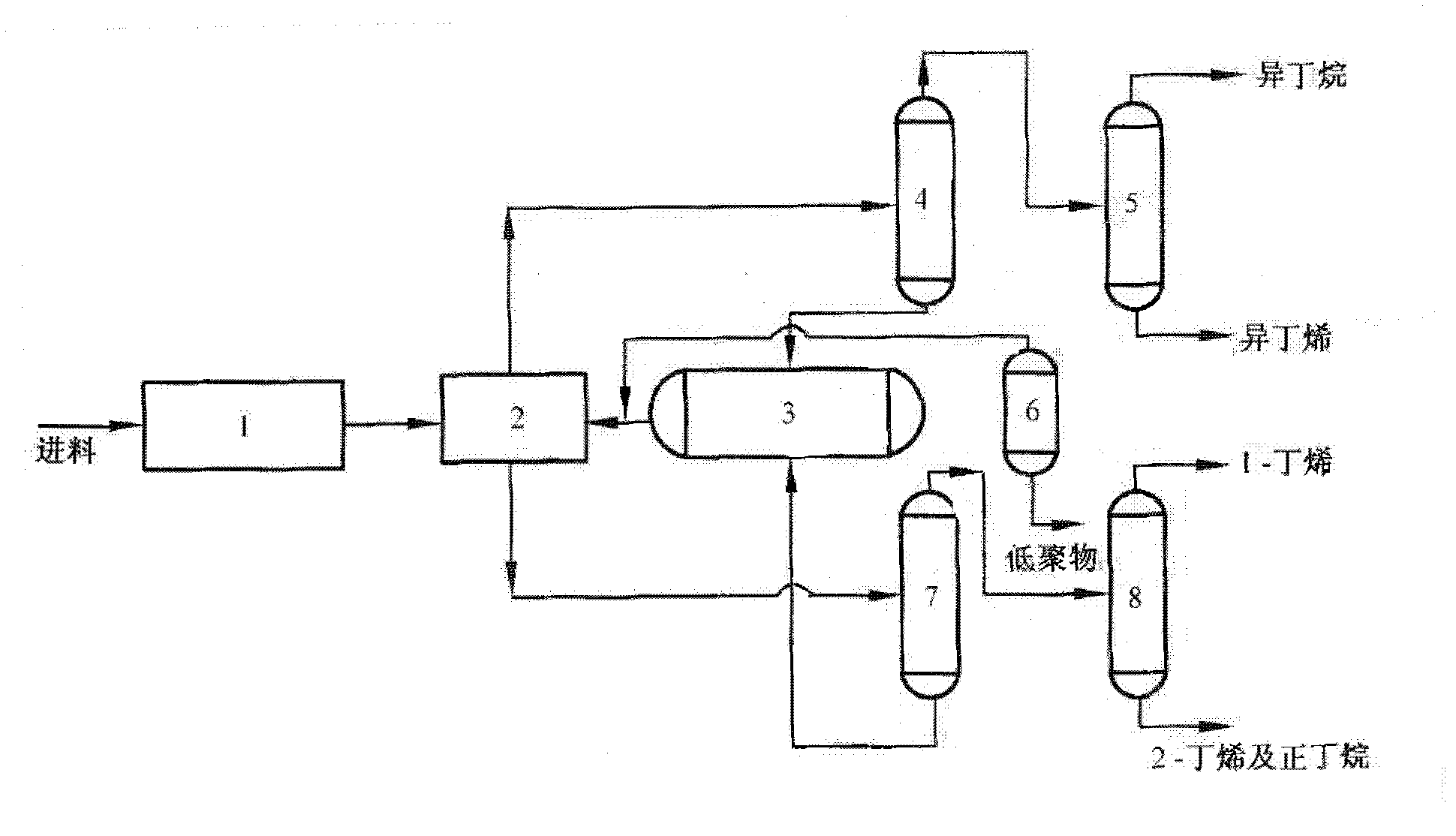

[0011] C4 material adopts calcium-modified 5A molecular sieve, multi-section bed adsorption method, at least three fixed bed adsorbers, that is, one adsorption, one desorption and one regeneration (burning) reactor; simultaneously add weight parts 0.1 of the polymerization inhibitor; using 1 times the weight of n-hexane and heptane as desorbent, the adsorption and desorption process is carried out at 100 ℃ and 101.325kPa pressure; the adsorption liquid is rectified to remove A small amount of n-butane and 2-butene, the final 1-butene purity > 99.0%; the vaporized C4 material is passed into the first adsorption tower washed with n-hexane in advance, and the desorbed n-hexane and isobutene are obtained by It is discharged from the top of the tower, and after isobutene is separated, n-hexane is returned to the system for recycling. The specific process is shown in figure 1 .

Embodiment 2

[0013] C4 material adopts calcium-modified 5A molecular sieve, multi-section bed adsorption method, at least three fixed bed adsorbers, that is, one adsorption, one desorption and one regeneration (burning) reactor; simultaneously add weight parts 1 times the polymerization inhibitor; 10 parts by weight of n-hexane and heptane were added as desorbents, and the adsorption and desorption processes were carried out at 100°C and 101.325kPa pressure; the adsorption liquid was rectified to remove A small amount of n-butane and 2-butene, the final 1-butene purity > 99.0%; the vaporized C4 material is passed into the first adsorption tower washed with n-hexane in advance, and the desorbed n-hexane and isobutene are obtained by It is discharged from the top of the tower, and after isobutene is separated, n-hexane is returned to the system for recycling. The specific process is shown in figure 1 .

Embodiment 3

[0015] C4 material adopts calcium-modified 5A molecular sieve, multi-section bed adsorption method, at least three fixed bed adsorbers, that is, one adsorption, one desorption and one regeneration (burning) reactor; simultaneously add weight parts 0.5 of the polymerization inhibitor; using 5 times the weight of n-hexane and heptane as the desorbent, the adsorption and desorption process is carried out at 100 ° C and 101.325kPa pressure; the adsorption liquid is rectified to remove A small amount of n-butane and 2-butene, the final 1-butene purity > 99.0%; the vaporized C4 material is passed into the first adsorption tower washed with n-hexane in advance, and the desorbed n-hexane and isobutene are obtained by It is discharged from the top of the tower, and after isobutene is separated, n-hexane is returned to the system for recycling. The specific process is shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com