Plant powder based plastic pencil and manufacturing method thereof

A manufacturing method and plant technology, applied in non-propelled pencils, pen holders, packaging items, etc., can solve the problems of high resin content, poor physical properties, high cost of pencils, etc., to save high-quality wood, moderate curling hardness, Eliminates the effect of harm to the human body

Inactive Publication Date: 2012-01-25

丁少忠

View PDF6 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] One of the technical problems to be solved by the present invention is to provide an energy-saving, low-carbon, and environmentally friendly plant powder-based plastic pencil, which can replace traditional wooden pencils, and can solve the problems of wooden pencils consuming a large amount of wood resources and requiring paint spraying and coloring. It is energy-saving and environmentally friendly, and it can solve the problems of high resin content used in the resin composite pencils in the prior art, which are not environmentally friendly, and the pencils made of degradable plastic raw materials have high costs and poor physical properties.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

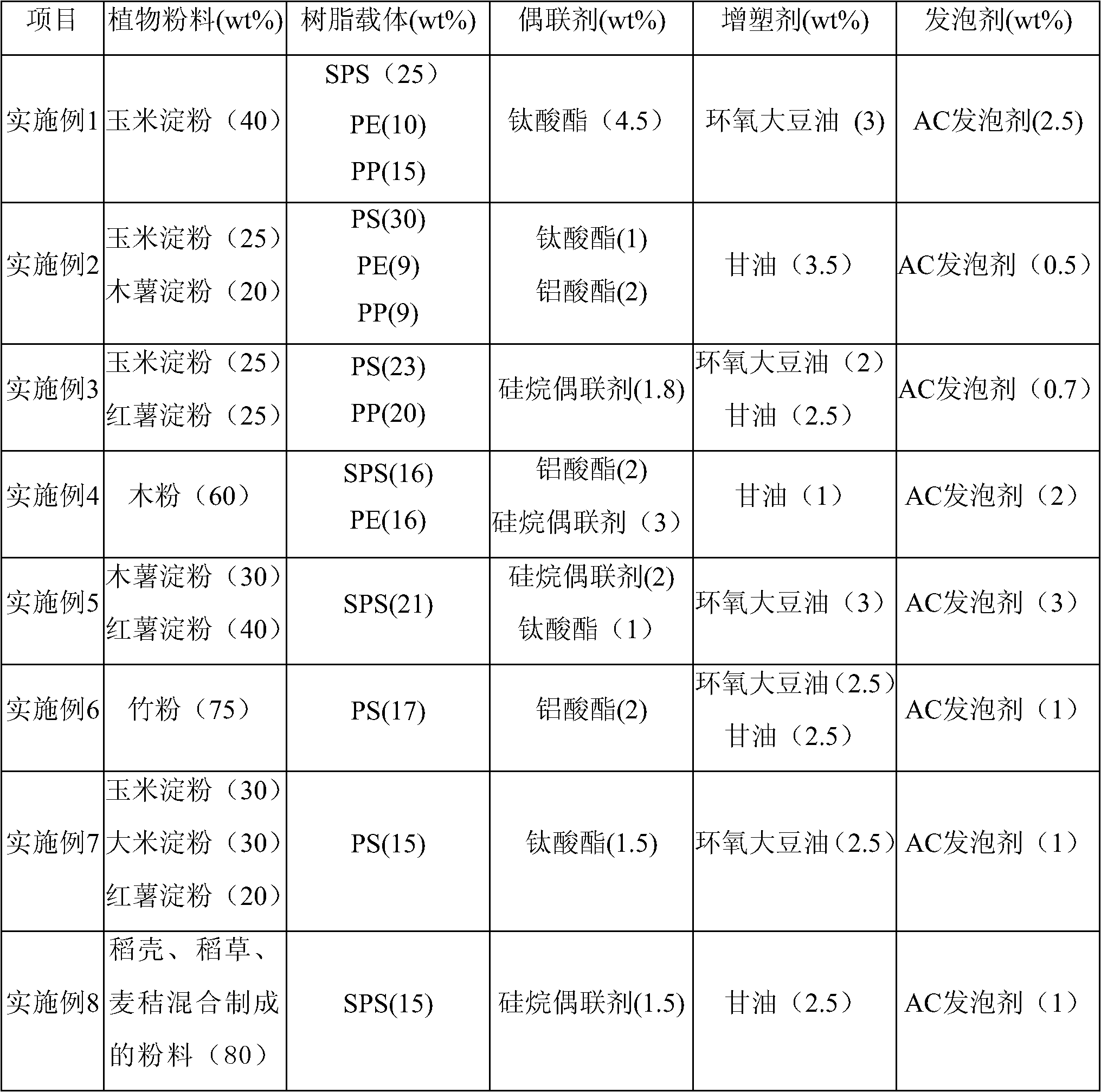

[0046] The method for the manufacture of plant powder-based plastic pencils of embodiments 1, 2, 4-7 is the same as that of embodiment 3, except that the penholder formulas used are different.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a pencil and a manufacturing method thereof, in particular to a plant powder based plastic pencil. A pencil holder of the pencil comprises the following components in percentage by weight: 40-80wt% of plant powder, 15-50wt% of resin carrier, 1-5wt% of plasticizer, 1-5wt% of coupling agent, and 0.5-3wt% of foaming agent. The invention further discloses a manufacturing method of the plant powder based plastic pencil, and the method comprises the steps of: raw material mixing, granulating, heating, synchronous molding of a pencil holder, a pencil peel and a cartridge, and the like. The plant powder based plastic pencil provided by the invention can replace a wooden pencil, has the advantages of good strength and toughness, easiness for peeling, no toxicity and environmental friendliness, simple production process and low cost, is beneficial to reduction of consumption in wood and fossil energy, and has the effects of saving energy, being low-carbon and protectingthe environment.

Description

technical field [0001] The invention mainly relates to a pencil and a manufacturing method thereof, in particular to a plant powder-based plastic pencil and a manufacturing method thereof, which has the remarkable characteristics of low carbon, energy saving and environmental protection. Background technique [0002] Pencil is a very widely used tool for writing and drawing. Its main structure is to form a strip lead embedded in the pen holder. The pen holder of a pencil is usually made of wood, and it is usually necessary to make a log into a pen holder in a shape such as a circle, a regular hexagon, or a regular octagon. Consumes a lot of high-quality wood. At present, my country's annual output of wooden pencils is about 8 billion, which is equivalent to destroying 600 square kilometers of forest every year and consuming 400,000 cubic meters of high-quality wood. The consumption of a large amount of forest resources has seriously damaged the ecological environment. In a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/06B29B9/06C08K5/053A45D40/20B43K19/16B43K3/00C08J9/10C08L3/02B29C47/06C08L53/02B29B7/18C08J9/06C08K5/1515C08L23/12C08L25/06C08L97/02

Inventor 丁少忠

Owner 丁少忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com