Preservation method for anaerobic ammonium oxidation granular sludge

An anaerobic ammonium oxidation and granular sludge technology, which is applied in anaerobic digestion treatment, biochemical equipment and methods, biological sludge treatment, etc. Problems such as obstacles to popularization and application, and long time-consuming startup and inhibited recovery can achieve the effect of avoiding adverse effects, facilitating long-term storage and maintaining activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

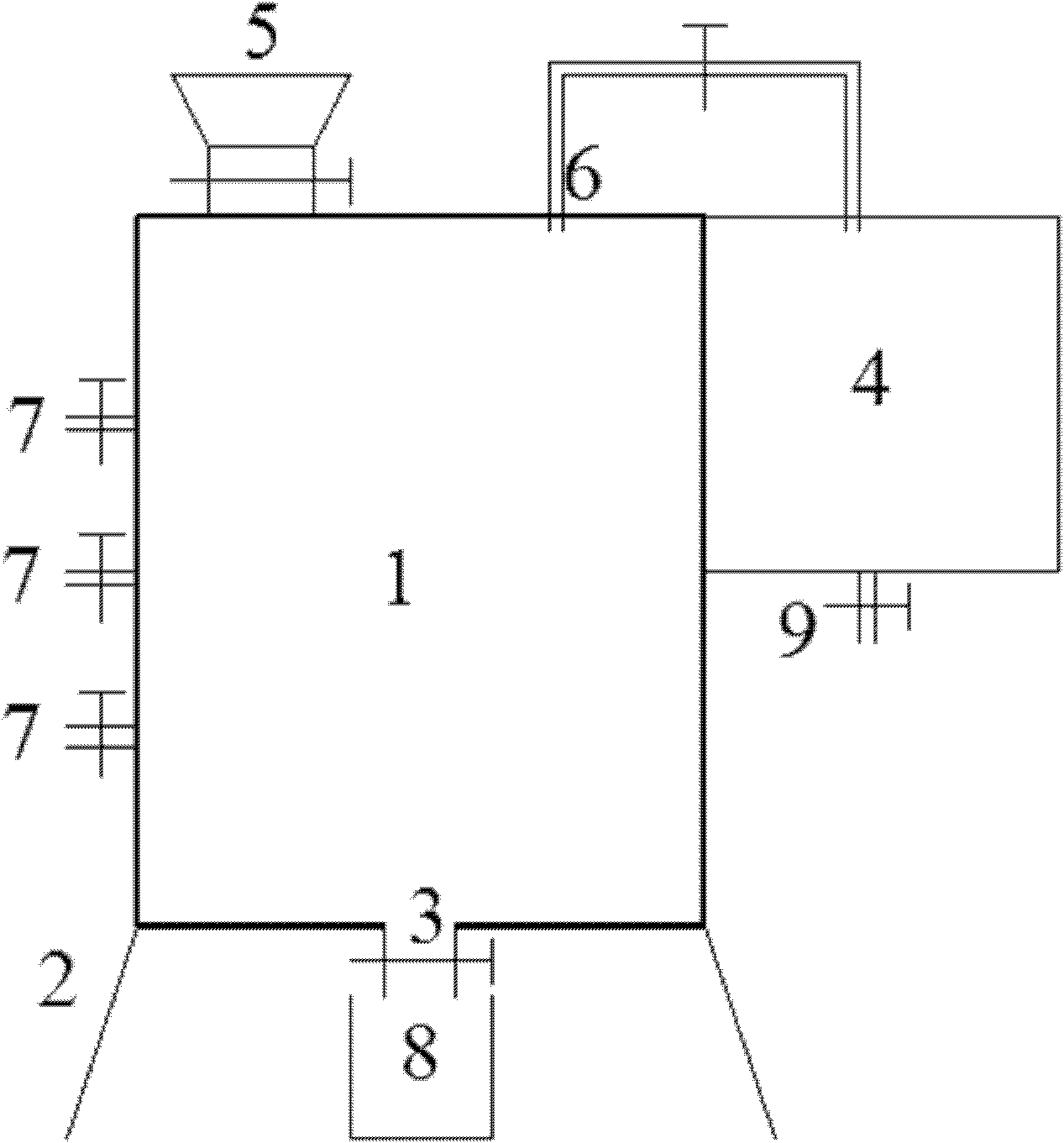

[0016] For the structure of the anaerobic ammonium oxidation granular sludge storage container, see figure 1 , which has a cylindrical or cuboid container body 1, a reactor base 2, a mud discharge port 3 below the container body, an inert gas buffer bag 4 above, a feeding (nutrient or sludge) port 5, the container body 1 and the inert The gas buffer bag 4 is connected through the exhaust pipe 6, and three water discharge valves 7 are scattered on the side wall of the container, and the sludge released from the mud discharge port 3 is put into the mud receiving bucket 8, and the inert gas buffer bag 4 is provided with a plus / The exhaust port 9 is decided to add inert gas or exhaust gas to the inert gas buffer bag 4 according to the actual situation.

[0017] Nutrients (or sludge) are added into the closed container 1 through the feeding port 5, and the anammox sludge in the container 1 consumes the matrix to maintain its anammox activity. The nitrogen produced by the anaerob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com