High-efficiency crystallization method of trichlorosucrose

A technology for sucralose and crystallization, which is applied in the field of high-efficiency crystallization of sucralose, can solve problems such as affecting product purity, production efficiency and yield, production cost impact, and product quality, and achieves shortened production cycle and low equipment requirements. , to avoid the effect of incomplete crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Sucralose was crystallized as follows:

[0013] (1) The formation of crystal nuclei: Concentrate the sucralose solution to a sugar content of 72%, put it into a jacket and keep the jacket temperature at 55°C, keep it warm for 1 hour, promote the formation of crystal nuclei, and obtain the trichloride that forms the crystal nuclei. Sucrose solution;

[0014] (2) Growth of crystal nuclei: program cooling of the sucralose solution forming the crystal nuclei, first in the range of 55-50 °C at a rate of 1 °C / 10 min; then in the range of 50-45 °C at a rate of 0.5 Cool at a rate of ℃ / 10min, and keep warm at 45°C for 1 hour; then cool at a rate of 1°C / 6min in the range of 45-35°C, and finally cool down to 25°C with circulating water, centrifuge and dry to obtain crystals.

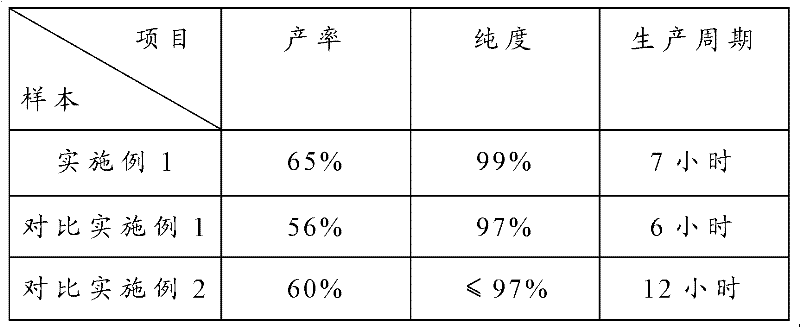

[0015] In order to illustrate the effect of the crystallization method of the present invention, the direct cooling crystallization method in the prior art is used as comparative example 1 and the natural c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com