Evaluation method for cracking resistance of cement-based material

A technology of cement-based materials and anti-crack performance, which is applied in the field of building materials, can solve the problems of inability to evaluate the anti-crack performance of cement-based materials, and the cracks are not concentrated, so as to reduce the risk of cracking, improve service life, and improve economic benefits and society. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

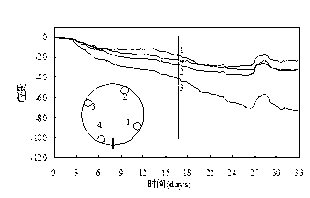

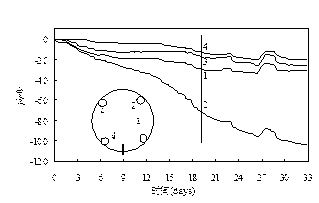

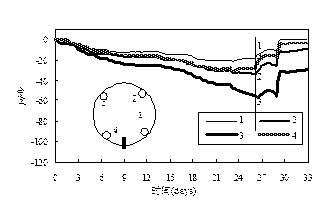

Image

Examples

Embodiment 1

[0030] 1. Test raw materials

[0031] P.O42.5 cement (Lianshi brand), Minjiang river sand (fine sand), gravel (Fuqing sand and gravel factory), fly ash (Huaneng Power Plant Class II fly ash), water reducer (Fujian Chuangxian Project Material Co., Ltd. CX-8 polycarboxylate superplasticizer), water.

[0032] 2. Concrete mix ratio

[0033] The designed concrete mix ratio is shown in Table 1, which is divided into fly ash mixed group (I group) and fly ash-free group (II group), and the strength grades are C30, C40 and C50. For example, C30I refers to the concrete mixed with fly ash and the strength grade is C30.

[0034] Table 1 Concrete mix ratio

[0035] Numbering Cement (kg / m 3 ) Water (kg / m 3 ) Fly ash (kg / m 3 ) Sand (kg / m 3 ) Stone (kg / m 3 ) Water reducer (kg / m 3 ) water-binder ratio Sand rate (%) C30Ⅰ 235 152 72 703 1240 3.07 0.53 37 C30Ⅱ 287 152 0 726 1235 2.87 0.53 37 C40Ⅰ 297 152 91 634 1235 3.88 0.42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com