Sic semiconductor device

A semiconductor, conductive type technology, used in semiconductor devices, electrical components, circuits, etc., to solve problems such as insufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

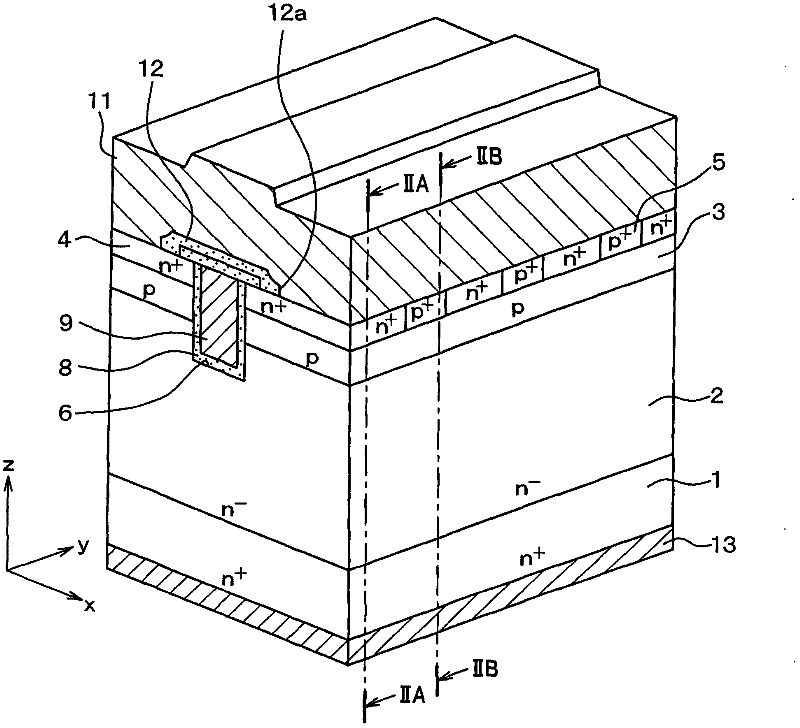

[0020] A MOSFET having an inversion type trench gate structure as an element in a SiC semiconductor device will be explained according to the first embodiment.

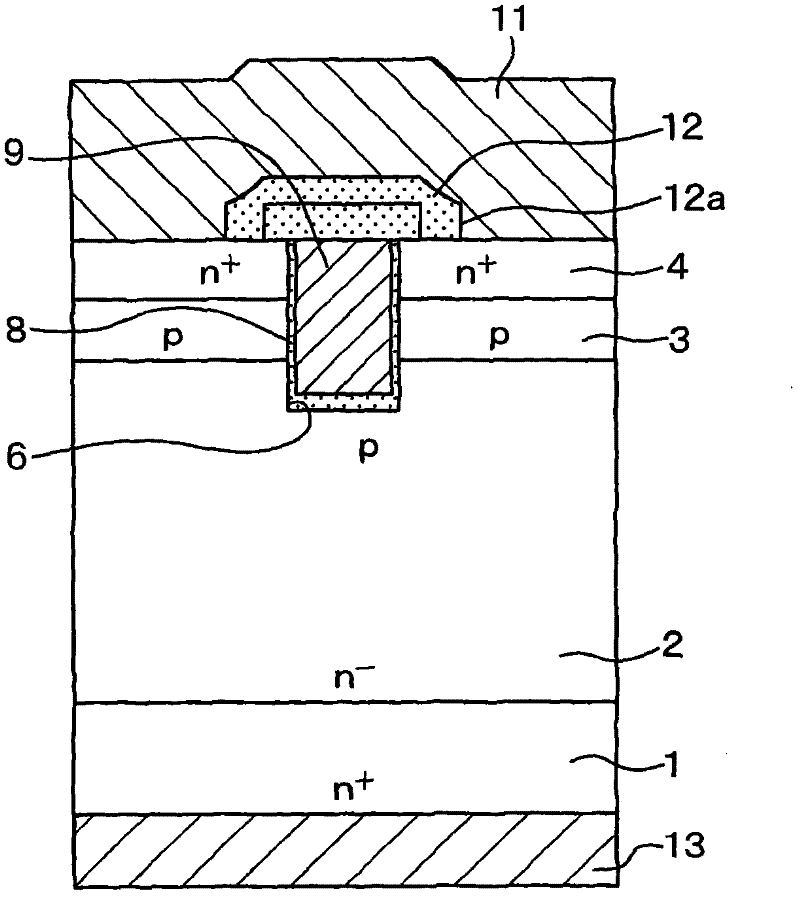

[0021] figure 1 A portion of a MOSFET according to the present embodiment is shown. figure 1 This part of the MOSFET corresponds to one cell of the MOSFET. In a MOSFET, multiple cells are arranged in a row, and each cell is shown in figure 1 middle. Figure 2A shows along the figure 1 A cross-sectional view of the MOSFET taken on line IIA-IIA, and this cross-sectional view is parallel to figure 1 X-Z plane in. Figure 2B shows along the figure 1 A cross-sectional view of the MOSFET taken on line IIB-IIB, and this cross-sectional view is parallel to figure 1 X-Z plane in. image 3 show figure 1 The upper layout view of the MOSFET in . figure 1 The MOSFET part corresponds to the image 3 District R in.

[0022] MOSFET consists of N made of SiC as the semiconductor substrate + Conductivity type substrate 1. ...

no. 2 example

[0037] In the SiC semiconductor device according to the second embodiment, on-resistance is improved.

[0038] Figure 4 is a cross-sectional view of a MOSFET with a trench gate structure in a SiC semiconductor device. Figure 4 corresponds to Figure 2B . Figure 5 yes Figure 4 Top layout view of the MOSFET in .

[0039] The cross-sectional structure of the SiC semiconductor device according to this embodiment is similar to that of figure 1 in the structure.

[0040] Such as Figure 4 As shown in , in this embodiment, the body layer 5 forms a contact portion with the source electrode 11 . Body layer 5 is not formed on the entire sidewall of trench 6 so that body layer 5 is separated from trench 6 . Source region 4 is formed on the entire sidewall of trench 6 . Specifically, the body layer 5 sandwiches the trench gate structure via the source region 4 . A portion of source region 4 arranged on a line passing through body layer 5 and perpendicular to the longitudinal...

no. 3 example

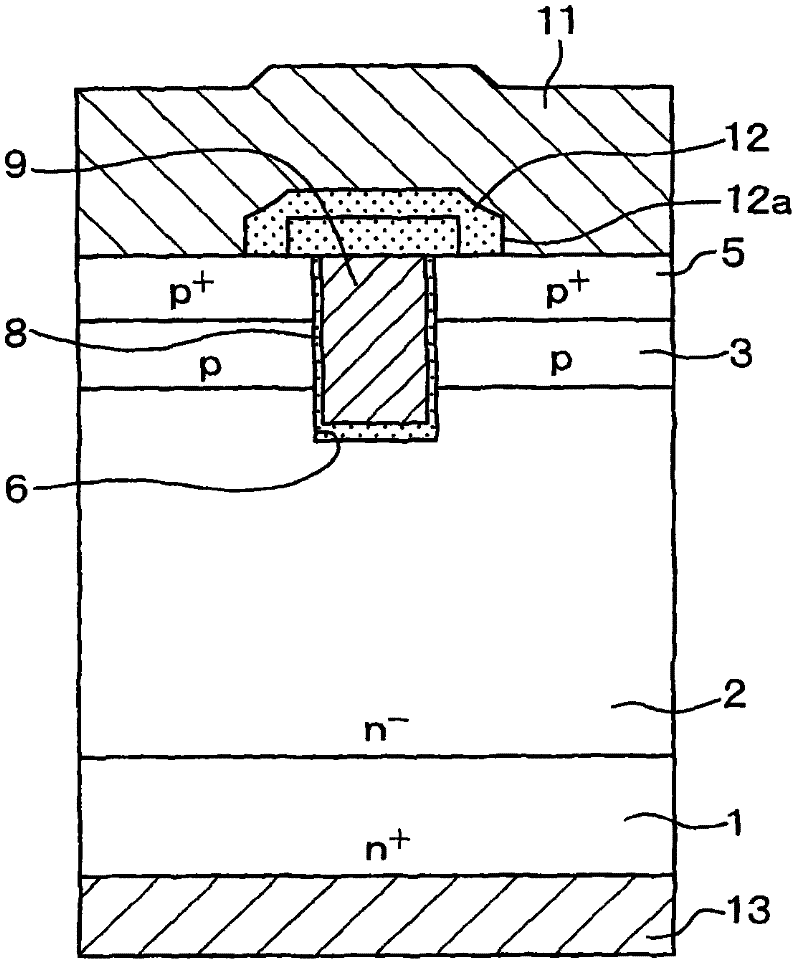

[0043] The breakdown voltage of the SiC semiconductor device according to the third embodiment is improved.

[0044] Figure 6 is a perspective view of a MOSFET having a trench gate structure in a SiC semiconductor device. Figure 7 yes Figure 6 Top layout view of the MOSFET in .

[0045] In the SiC semiconductor device, the deep layer 10 of the P conductivity type is formed in a part of the drift layer 2 disposed under the base region 3 and opposite to the body layer 5 . The deep layer 10 extends in a direction perpendicular to the longitudinal direction of the trench 6, and the extending direction of the deep layer 10 is the normal direction of the channel forming portion contacting the sidewall of the trench 6 (i.e., Figure 6 in the X direction). The deep layer 10 has a deeper depth than the bottom of the trench 6 . The depth of the deep layer 10 from the surface of the drift layer 2 is for example in the range between 2.6 micrometers and 3.0 micrometers such that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com