Electrolyte for manufacturing emulsion storage battery and manufacturing method thereof

An electrolyte and battery technology, applied in lead-acid batteries and other directions, can solve problems such as cracks, battery scrap, starter battery bulging, etc., and achieve the effect of wide operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the mother liquor and the electrolyte solution for the electrolyte of the present embodiment that is used to manufacture the emulsion storage battery is as follows:

[0037] 1) Choose a pH value of 9, containing 30wt% SiO 2 SiO 2 · n H 2 O 5kg, 35kg of dilute sulfuric acid with a density of 1.34g / cm3, and 5.5kg of pure water are mixed and stirred evenly to make the mother liquor of the electrolyte; 2) Seal the high-pressure container, and then apply a high-voltage magnetic field of 800V to it; 3) Pass through the high-voltage magnetic field Treated as an electrolyte solution containing a saturated magnetic flux.

[0038]

Embodiment 2

[0040] The preparation method of the mother liquor and the electrolyte solution for the electrolyte of the present embodiment that is used to manufacture the emulsion storage battery is as follows:

[0041] 1) Choose a pH value of 10, containing 45wt% SiO 2 SiO 2 · n H 2 O 5.2kg, 44kg of carbonic acid with a density of 1.44g / cm3, and 10kg of pure water are mixed and stirred evenly to make the mother liquor of the electrolyte; 2) Seal the high-pressure container, and then apply a high-voltage magnetic field of 1000V to it; 3) After high-voltage magnetic field treatment It becomes an electrolyte solution containing a saturated magnetic flux.

[0042]

Embodiment 3

[0044] The preparation method of the mother liquor and the electrolyte solution for the electrolyte of the present embodiment that is used to manufacture the emulsion storage battery is as follows:

[0045] 1) Choose a pH value of 9.5, containing 40wt% SiO 2 SiO 2 · n H 2 O 6kg, density 1.39g / cm 3 50kg of dilute sulfuric acid and 10kg of pure water are mixed and stirred evenly to make the mother liquor of the electrolyte; 2) Seal the high-pressure container, and then apply a high-voltage magnetic field of 900V to it; 3) After high-voltage magnetic field treatment, it becomes an electrolyte containing saturated magnetic flux.

[0046]

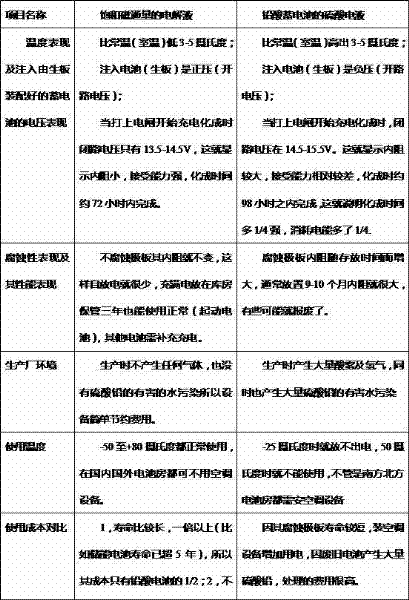

[0047]Through experimental testing, the electrolytes of the above-mentioned embodiments all have the characteristics of small internal resistance, low generation temperature, and short formation time, and do not produce any gas during production, and there is no harmful water pollution of lead sulfate; using this electrolyte to produce The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com