Casting and continuous rolling method and plant to make long metal rolled products

一种产品、金属的技术,应用在金属轧制、照明和加热设备、炉子组件等方向,达到避免材料和能量的损失、好满负荷生产量、避免中断的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

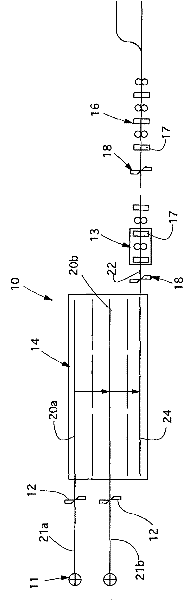

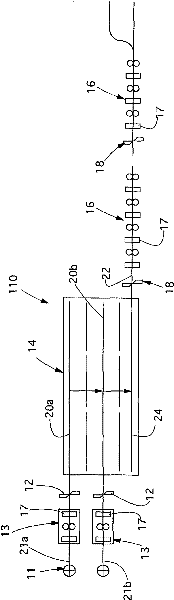

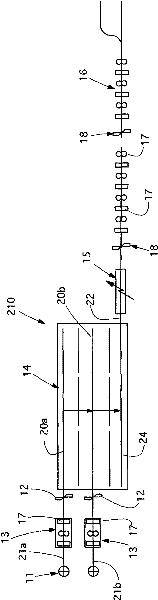

[0071] With reference to the accompanying drawings, figure 1 A first example of a layout 10 of a plant for producing elongate products according to the invention is shown.

[0072] figure 1 Layout 10 in , among the essential elements shown, comprises a continuous casting machine 11 comprising two casting lines respectively 21a and 21b running parallel to each other, each casting The wire uses a mold or other device suitable for casting billets of square or rectangular cross-section and of various shapes and sizes, with straight, curved, concave or convex sides or others. Some examples of sections that can be cast using the present invention are in Figure 9-12 shown in Figure 9-12 Respectively show a rectangular section with straight and parallel sides ( Figure 9 ), a section with short sides with convex curvature and straight and parallel long sides ( Figure 10 ), a section with short sides with convex curvature at the center and straight and parallel long sides ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com