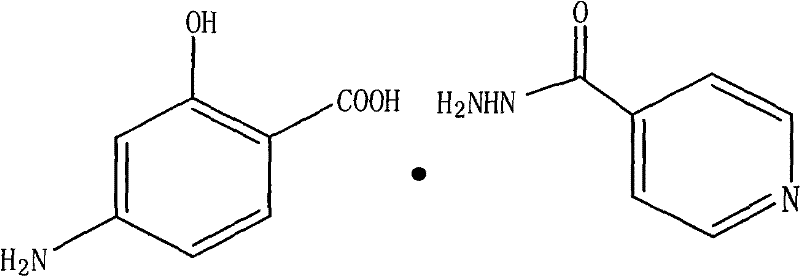

Preparation method of isoniazid para-aminosalicylate

A technology of isoniazid p-aminosalicylic acid and sodium aminosalicylate, applied in the field of preparation of isoniazid p-aminosalicylic acid, can solve the problem that the properties of aminosalicylic acid are unstable, it is difficult to buy pure finished products, Affect the production process and other problems to achieve the effects of stable quality and yield, good water solubility, and reduced raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 100kg of sodium p-aminosalicylate into 250kg of purified water, stir, add hydrochloric acid, adjust the pH to 3.5, add 700kg of ethyl acetate, after sufficient extraction, separate layers, discard the water layer and wash the extract with water. Add 65 kg of isoniazid to the extract, stir and raise the temperature to 75-80°C, react for 40 minutes, cool down to -10-5°C, keep warm and crystallize for 80 minutes. After centrifugation, the obtained solids are boiled and dried at 60-65°C to obtain the finished product of isoniazid p-aminosalicylic acid, which is a bright yellow rhombic crystal. The finished product content is 98.5%, and the yield is 97%.

Embodiment 2

[0032] Add 100kg of sodium p-aminosalicylate into 150kg of purified water, stir, add sulfuric acid, adjust the pH to 4.0, add 850kg of propyl acetate, after fully extracting, separate layers, discard the water layer and wash the extract with water. Add 60kg of isoniazid to the extract, stir and heat up to 65-70°C, react for 40 minutes, cool down to 5-10°C, and keep warm for 120 minutes for crystallization. After centrifugation, the obtained solid is boiled and dried at 65-70°C to obtain the finished product of isoniazid p-aminosalicylic acid, which is a bright yellow diamond-shaped crystal. The finished product content is 98.3%, and the yield is 95%.

Embodiment 3

[0034] Add 100kg of sodium p-aminosalicylate into 200kg of purified water, stir, add hydrochloric acid, adjust the pH to 3.5, add 700kg of methyl formate, after sufficient extraction, separate layers, discard the water layer and wash the extract with water. Add 50kg of isoniazid to the extract, stir and heat up to 50-55°C, react for 30 minutes, then cool down to -5-0°C, keep warm and crystallize for 80 minutes. After centrifugation, the resulting solid is boiled and dried at 50-55°C to obtain the finished product of isoniazid p-aminosalicylic acid, which is a bright yellow diamond-shaped crystal. The finished product content is 98.1%, and the yield is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com