Bilayer planning method for intelligent scheduling for steelmaking-continuous welding production

A technology of intelligent scheduling and production scheduling, applied in the field of information, can solve the problems of insufficient implementation of the production process, the setting of optimization goals and the selection of optimization variables lack of global consideration, and achieve the effect of low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

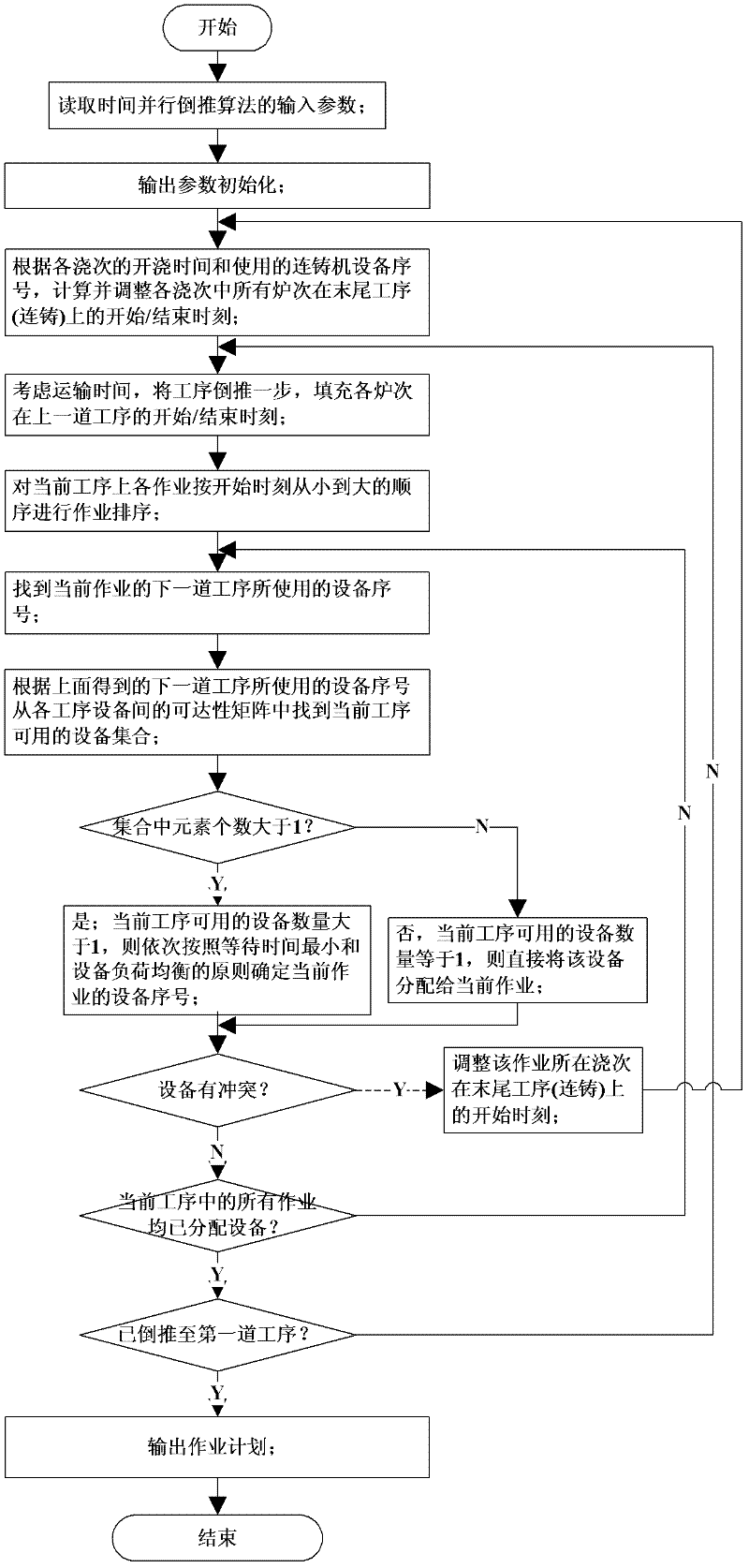

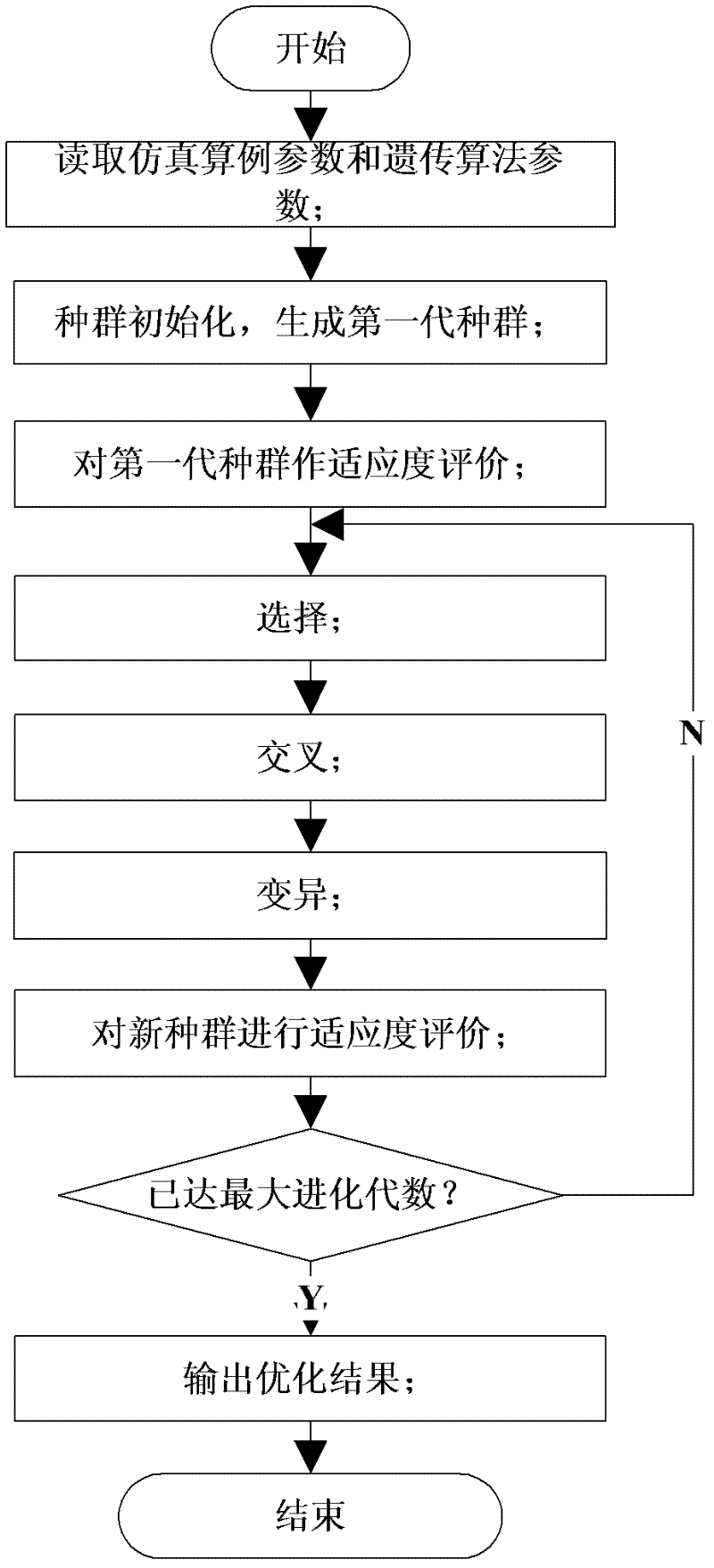

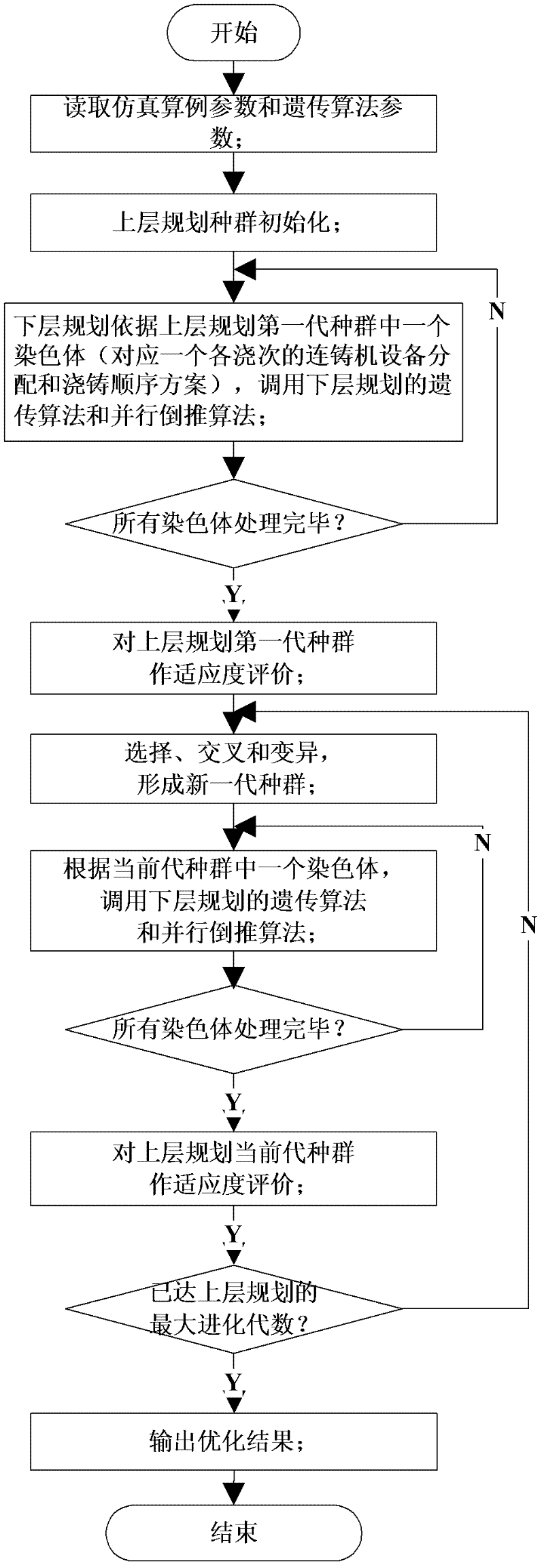

[0092] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0093] Taking the actual production scheduling problem of a certain factory as an example, the present invention will be further described in conjunction with the accompanying drawings.

[0094] The main process flow of a steelmaking-continuous casting plant is: desulfurization → converter → LF → RH → continuous casting, in which the number of equipment in each process is: 5 desulfurization stations, 5 converters, 4 LF furnaces, and 2 RH furnaces seat, and 4 continuous casting machines, of which: 1# to 3# are slab continuous casting machines, and 4# are billet continuous casting machines.

[0095] The implementation process of the two-level planning method for intelligent scheduling of steelmaking-continuous casting production is mainly carried out in the following steps:

[0096] 1. Input process parameters, including the number of equipment in each p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com