Continuous production technology of polytetrafluoroethylene membrane with electromechanical energy transition function

A polytetrafluoroethylene piezoelectric and polytetrafluoroethylene technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, circuits, electronic equipment, etc., can solve the problems of low storage stability, weakened piezoelectric effect, and loss of and other problems, to achieve excellent piezoelectric performance, high thermal temperature resistance, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

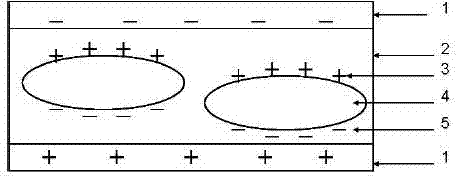

[0034] see figure 1 As shown in the schematic diagram of the piezoelectric electret material microstructure, space charge distribution, and piezoelectric effect of the present invention, a continuous production process of polytetrafluoroethylene electromechanical energy conversion functional membranes, including microporous composite membranes The thermal bonding step and the charging step of the composite film are two parts, wherein,

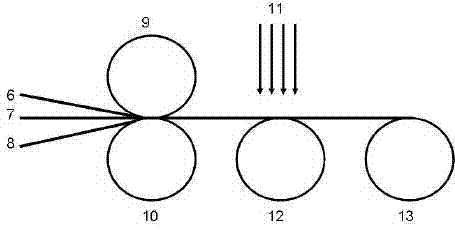

[0035] The thermal bonding step of the microporous structure composite membrane is: adopt two layers of dense PTFE films 6 and 8 with a thickness of 5 μm and an expanded porous PTFE film 7 with a thickness of one layer of 5 μm, and sandwich the expanded porous PTFE film 7 between the two layers. Form a film system between the dense PTFE films 6 and 8, and then import two upper and lower hot pressing rollers 9 and 10 with a diameter of 150mm to carry out hot pressing bonding, and the embossing on the surface of the upper and lower hot pressing ...

Embodiment 2

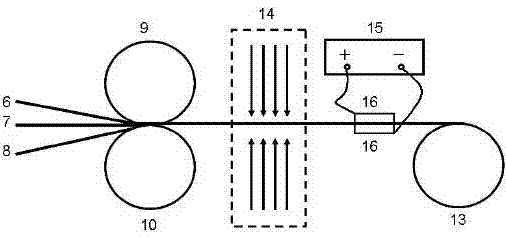

[0042] A film surface electroplating system 14 and a contact charging system 15, 16 are arranged between the upper and lower hot pressing rollers 9, 10 and the winding roller 13.

[0043] A continuous production process of polytetrafluoroethylene electromechanical energy conversion functional film, including two parts: the thermal bonding step of the microporous structure composite film and the charging step of the composite film, wherein,

[0044] The thermal bonding step of the microporous structure composite membrane is: adopt two layers of dense PTFE film with a thickness of 20 μm and a layer of expanded porous PTFE film with a thickness of 400 μm, sandwich the expanded porous PTFE film between the two layers of dense PTFE film Form a film system between them, through two upper and lower hot pressing rollers 9, 10 with a diameter of 150mm, wherein the embossing on the surface of the upper hot pressing roller 9 is a cross pattern, the temperature is 420°C, and the upper ...

Embodiment 3

[0049] Two layers of 50 μm thick turning PTFE films 6, 8 and one layer of 2 μm thick expanded porous PTFE films 7 are used, and the expanded porous PTFE films 7 are sandwiched between two layers of dense PTFE films 6, 8 to form a film system, and then imported Two upper and lower hot pressing rollers 9 and 10 with a diameter of 150 mm are used for thermocompression bonding. The embossing on the surface of the upper and lower hot pressing rollers 9 and 10 is a cross pattern, and the temperature is 150 ° C. The upper and lower hot pressing rollers The pressure applied by 9 and 10 on the film system is 200MPa, and the speed of the film system traveling between the upper and lower hot pressing rollers 9 and 10 is 10m / min, and the microporous structure PTFE composite film is obtained after hot pressing;

[0050] see figure 2 As shown in the process schematic diagram of the present invention adopting corona polarization to produce PTFE piezoelectric electret film, the charging of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com