Mixture for preparing C55 high-intensity ultra-high-pumping concrete

An ultra-high pumping and mixture technology, which is applied in the field of preparing C55 high-strength ultra-high pumping concrete mixture, can solve the problems of concrete workability and difficult control of pumpability, and achieve good pumpability and slump The effect of small loss and meeting the requirements of the intermittent time limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0131] Embodiment 1 is used to prepare the mixing ratio design of each component in the mixture of C50 high-strength ultra-high pumping concrete

[0132] 1) The design of concrete mix ratio should comply with the "Design Regulations for Ordinary Concrete Mix Ratio" (JTJ55-2000).

[0133] 2) The concrete preparation strength is calculated according to the following formula: fcu.o≥fcu.k+1.645σ,

[0134] Where fcu.o-concrete preparation strength (MPa),

[0135] fcu.k - standard value of concrete cube compressive strength (MPa),

[0136] σ-Standard deviation of concrete strength (MPa), should be based on no less than 30 sets of statistical data of standard specimens with the same mix ratio; if there is no accurate statistical standard deviation, the value is 6MPa according to the specification.

[0137] 3) The concrete sand rate is controlled between 38% and 45%, and the water-cement ratio is between 0.34 and 0.38.

[0138] 4) Concrete slump is controlled between 180mm and 220m...

Embodiment 2

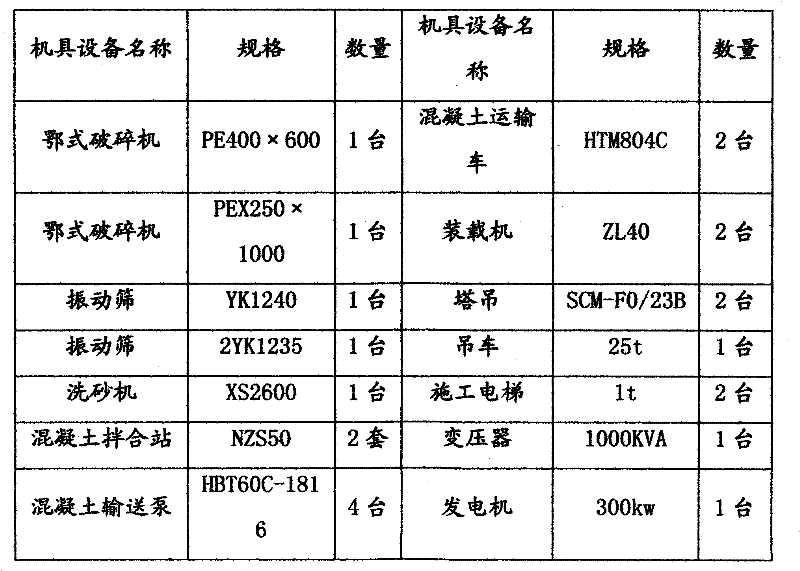

[0143] The mixing of embodiment 2 concrete

[0144] 1. The concrete prepared in Example 1 is mixed using an electronic automatic metering mixing station for centralized mixing. The mixing measurement is based on mass, and its deviation should meet the requirements of Table 1.

[0145] Table 1 Concrete mixing measurement allowable deviation

[0146]

[0147] 2. Measuring equipment should have a valid qualification certificate issued by the legal metrology department. Before formal weighing, the measuring equipment should be checked at zero point.

[0148] 3. The concrete mixing time is 120s~150s.

[0149] 4. Concrete every 30m 3 Take a sample once to check the slump of the concrete. When the measured slump and the set slump exceed ±30mm, the reason should be found out, and the stirring production can only be continued after the solution is resolved. When testing slump, the cohesion and water retention of concrete should also be observed.

[0150] 5. When the measured mo...

Embodiment 3

[0151] Example 3 Concrete Transportation

[0152]1. The concrete prepared in Example 1 is transported using a concrete transport vehicle and a delivery pump.

[0153] 2. After the concrete is transported to the pouring site, there will be no segregation, no stratification, no change in composition, and the slump necessary for construction can be guaranteed. If segregation or stratification occurs in the concrete mixture, the concrete mixture should be mixed again.

[0154] 3. During the transportation of the concrete mixer truck, the mixing drum is constantly stirred at a speed of 1 to 3 rpm. The mixing drum should be stirred for 1 to 2 minutes before being transported to the site for unloading.

[0155] 4. When the concrete is transported to the designated unloading site, its slump should be tested, and the measured slump value meets the construction requirements.

[0156] 5. When pumping concrete is used, the continuous operation of the concrete pump should be ensured. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com