Structural strengthening sprayable mortar composition and preparation process thereof

A composition and mortar technology, applied in building construction, building maintenance, construction, etc., can solve the problems of affecting the continuity of construction progress, increasing labor time and labor intensity, water loss, etc., to improve sprayable construction performance, easy to Large-scale application and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

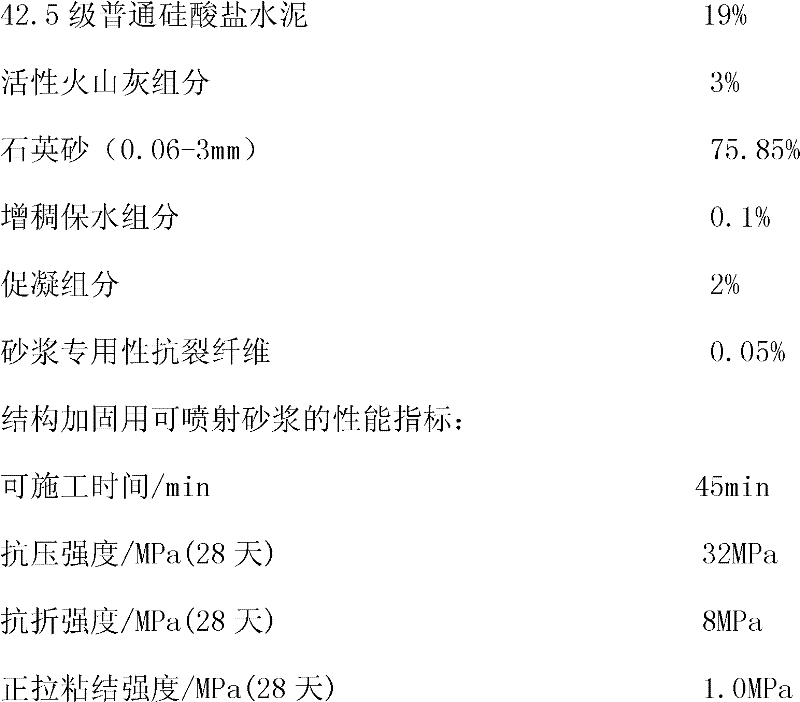

[0018] The proportion of each component of the sprayable mortar for structural reinforcement is as follows:

[0019]

[0020]

[0021] The implementation steps of this embodiment: first premix and mix 3% active volcanic ash component, 0.1% thickening and water-retaining component, 2% coagulation-promoting component, and 0.05% anti-cracking fiber for mortar in proportion to form a mixture, and then The uniformly stirred mixture, 19% of grade 42.5 ordinary Portland cement, and 3% of quartz sand are weighed in proportion, mixed, stirred evenly, and packaged.

Embodiment 2

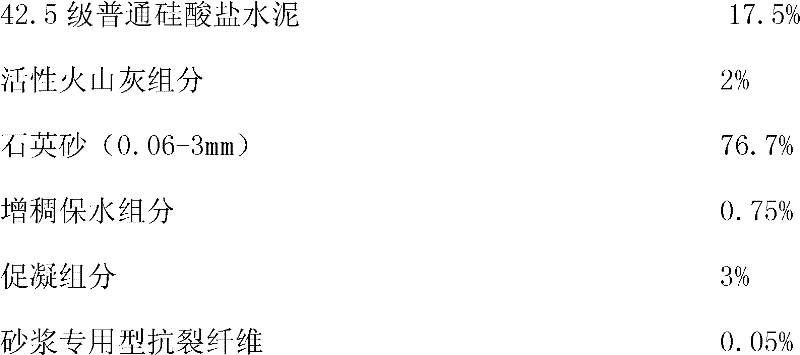

[0023] The proportion of each component of the sprayable mortar for structural reinforcement is as follows:

[0024]

[0025] Performance indicators of sprayable mortar for structural reinforcement:

[0026]

[0027]

[0028] The implementation steps of this embodiment: directly add 2% of the active pozzolan component, 0.75% of the thickening and water-retaining component, 3% of the coagulation-promoting component, 0.05% of the anti-cracking fiber for mortar, and 17.5% of the 42.5-grade ordinary Portland cement. % and 76.7% of quartz sand are weighed in proportion, mixed, stirred evenly, and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com