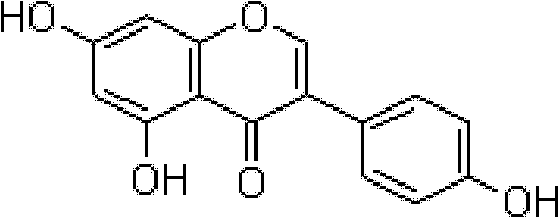

Novel technology for extracting genistein

A technology of genistein and a new process, applied in the direction of organic chemistry, etc., can solve the problems of difficult industrial production, organic solvent residue, high production cost, etc., and achieve the goal of increasing product yield and content, low cost, and increasing yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Sophora japonica was crushed into 30 meshes, weighed 10kg, added 80kg of water, heated and refluxed for 3 times, 4 hours each time, combined decoction, concentrated until the specific gravity of the extract was 1.16. Add 245 kg of 2% dilute sulfuric acid, heat to reflux for 0.5 hours, and hydrolyze at 70°C. After cooling, filter, wash the filter cake with water to remove acid, and obtain a black crude product. Add 20 times the amount (mass ratio) of methanol to the crude product for heating and dissolving, cool and crystallize, and then change to 20 times the amount (mass ratio) of absolute ethanol for heating and dissolving after repeated crystallization, cool and crystallize, then vacuum dry to obtain genistein crystals 160 grams, the yield is 1.6%, and the purity of genistein is greater than 98%.

Embodiment 2

[0027] Sophora japonica was crushed into 60 mesh, weighed 10kg, added 90kg of water, heated and refluxed for 3 times, 4 hours each time, combined decoction, concentrated until the specific gravity of the extract was 1.18. Add 245 kg of 2% dilute sulfuric acid, heat to reflux for 0.5 hours, and hydrolyze at 80°C. After cooling, filter, wash the filter cake with water to remove acid, and obtain a black crude product. Add 30 times the amount (mass ratio) of methanol to the crude product for heating and dissolving, cool and crystallize, and then use 30 times the amount (mass ratio) of absolute ethanol to heat and dissolve after repeated crystallization, cool and crystallize, then vacuum dry to obtain genistein crystals 183 grams, the yield is 1.83%, and the purity of genistein is greater than 98%.

Embodiment 3

[0029] Sophora japonica was crushed into 30 meshes, weighed 10kg, added 100kg of water, heated and refluxed for 3 times, 4 hours each time, combined decoction, and concentrated until the specific gravity of the extract was 1.16. Add 245 kg of 2% dilute hydrochloric acid, heat to reflux for 0.5 hours, and hydrolyze at 90°C. After cooling, filter, wash the filter cake with water to remove acid, and obtain a black crude product. Add 30 times the amount (mass ratio) of methanol to the crude product for heating and dissolving, cool and crystallize, and then use 30 times the amount (mass ratio) of absolute ethanol to heat and dissolve after repeated crystallization, cool and crystallize, then vacuum dry to obtain genistein crystals 195 grams, the yield is 1.95%, and the purity of genistein is greater than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com