Monocomponent ultraviolet light self-crosslinking type acrylate copolymer coating, and synthetic method and application thereof

An acrylate and ultraviolet light technology, applied in the direction of coating, can solve the problems of easy yellowing of the coating film, strong odor, limited development space, etc., and achieve the effect of maintaining stable performance, stable performance and improved temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

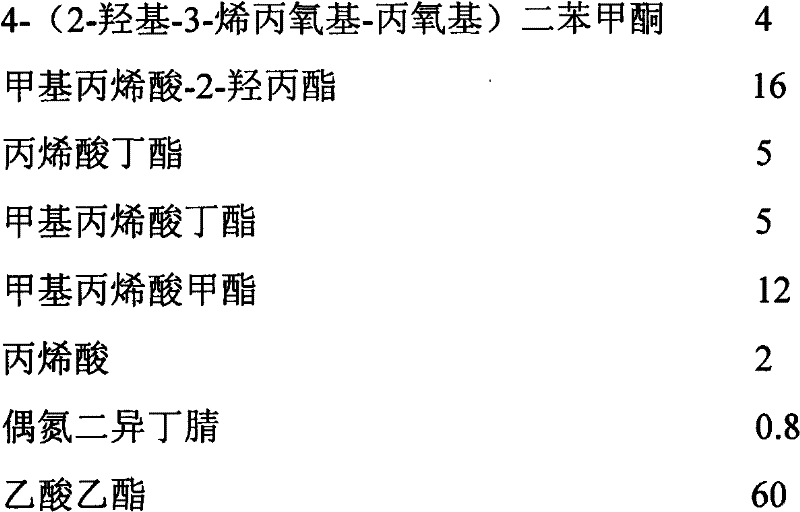

[0036] The one-component UV self-crosslinking acrylate copolymer coating of the present embodiment is synthesized from the following components (parts by weight):

[0037]

[0038] The specific synthesis process is as follows: Put UV-active monomers, photo-crosslinking functional monomers, other monofunctional monomers, initiators and solvents into the reaction kettle and stir to mix evenly. A one-component UV self-crosslinking acrylate copolymer coating is obtained.

[0039] The single-component UV self-crosslinking acrylate copolymer coating obtained above was coated on the base material, and after the solvent was evaporated, the photocrosslinking was carried out in a UV curing device. The irradiation energy of the UV self-crosslinking was 500mJ. After testing, the cross-linking degree of the coating is 80% after ultraviolet light irradiation, and the temperature resistance performance is increased by 40°C.

Embodiment 2

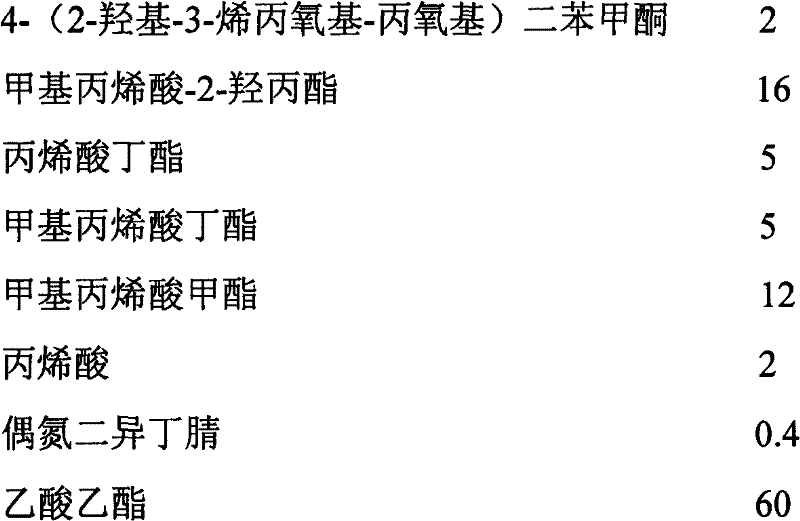

[0041] The one-component UV self-crosslinking acrylate copolymer coating of the present embodiment is synthesized from the following components (parts by weight):

[0042]

[0043] Synthetic process is identical with embodiment 1. The obtained one-component UV self-crosslinking acrylate copolymer coating is coated on the substrate, and after the solvent is evaporated, the photocrosslinking is carried out in a UV curing device, and the irradiation energy of the UV self-crosslinking is 500mJ. After testing, the cross-linking degree of the coating is 60% after ultraviolet light irradiation, and the temperature resistance performance is increased by 20°C.

Embodiment 3

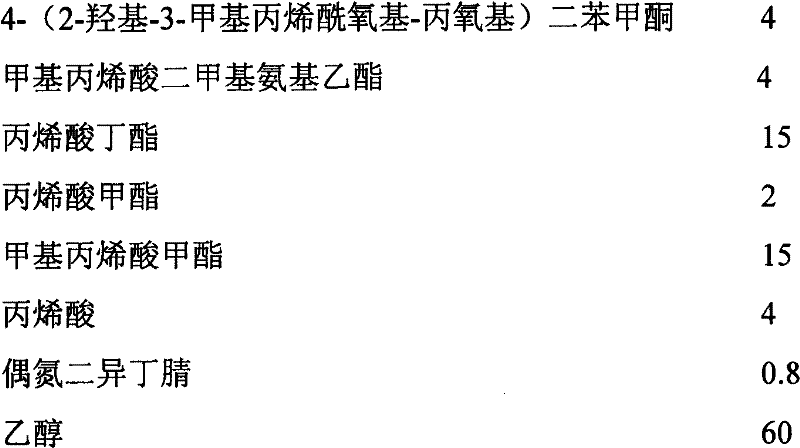

[0045] The one-component UV self-crosslinking acrylate copolymer coating of the present embodiment is synthesized from the following components (parts by weight):

[0046]

[0047] Synthetic process is identical with embodiment 1. The obtained one-component UV self-crosslinking acrylate copolymer coating is coated on the substrate, and after the solvent is evaporated, the photocrosslinking is carried out in a UV curing device, and the irradiation energy of the UV self-crosslinking is 500mJ. After testing, the cross-linking degree of the coating is 90% after ultraviolet light irradiation, and the temperature resistance performance is increased by 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com