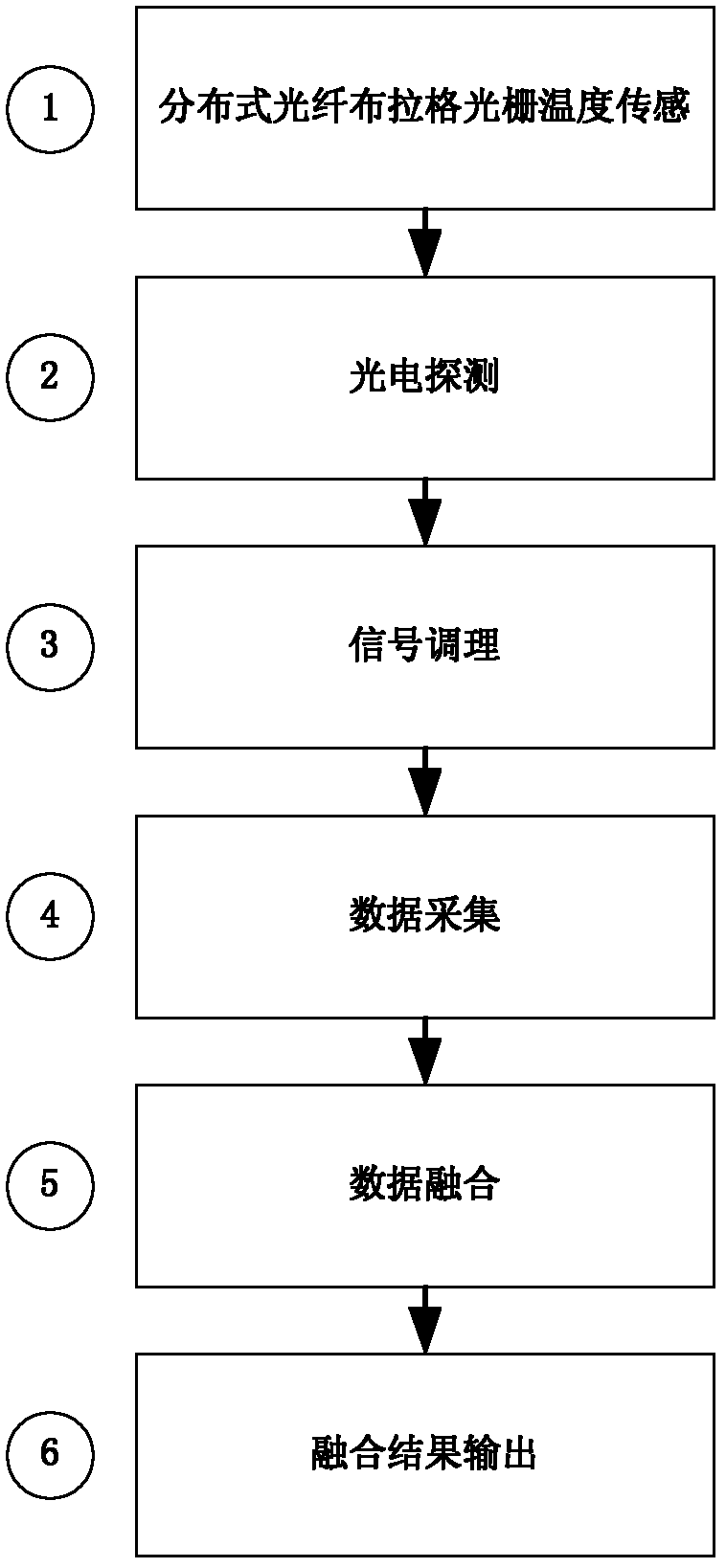

Distributed grating temperature measurement method based on two-time data fusion technology

A technology of temperature measurement and distributed optical fiber, which is applied in the direction of physical/chemical change thermometers, thermometers, measuring devices, etc., can solve the problems of inaccurate measurement results, grating sensors are susceptible to interference, etc., and achieve low hardware requirements and overcome Faults, Effects of Robustness Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

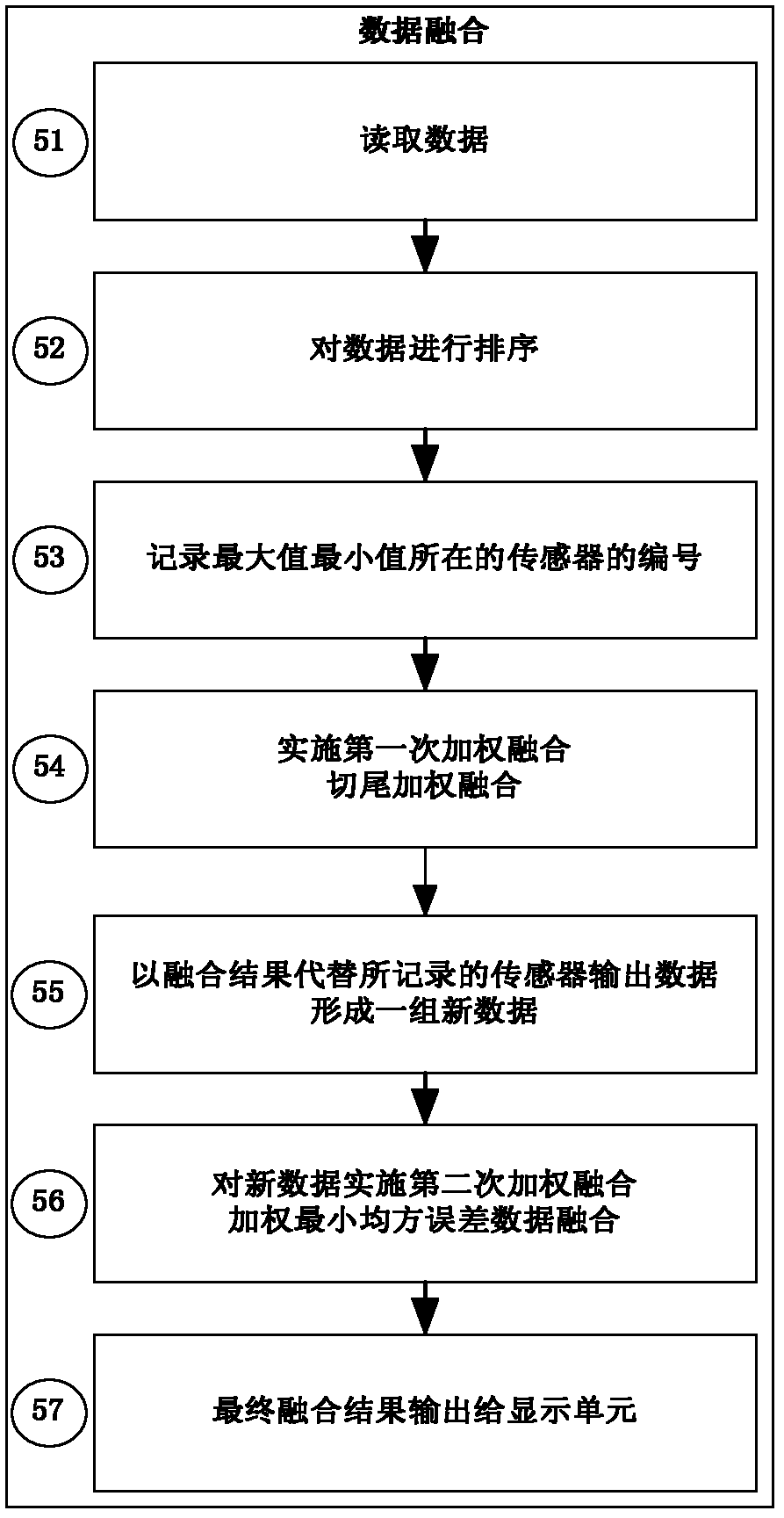

Method used

Image

Examples

Embodiment

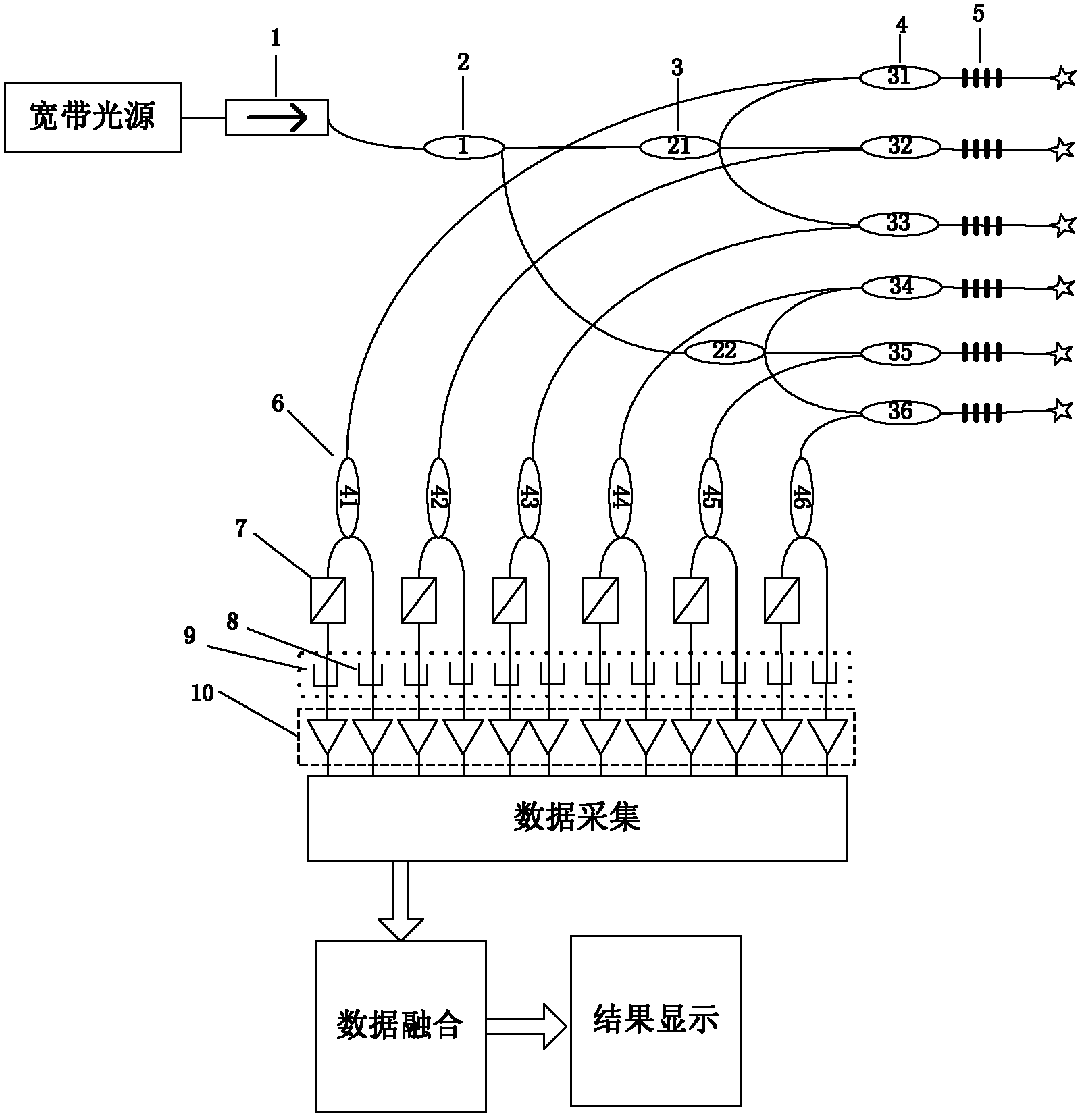

[0028] Such as image 3 As shown, take the first road as an example, this example is to measure in a closed environment.

[0029] 1. Distributed grating temperature measurement: The light emitted from the broadband light source enters the first coupler 2 after passing through the isolator 1, and then enters the fiber Bragg grating 5 through the second coupler 3 and the third coupler 4, where the grating is affected by the temperature Affected by other factors, part of the light is reflected back to the third coupler 4, and the reflected light is divided into two identical optical signals by the fourth coupler 6, one of which passes through the hypotenuse filter 7, and the other is not processed.

[0030] 2. Photoelectric detection: the two optical signals are simultaneously detected by photodetectors 8 and 9 respectively. At this time, the signal passing through the hypotenuse filter 7 is detected by the photodetector 9 to obtain a current signal of The current signal obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com