Method for measuring overburden porosity with water in permeation fluid mechanics experiment

A technology of mechanical experiments and measurement methods, applied in measurement devices, scientific instruments, permeability/surface area analysis, etc., can solve problems such as inability to simulate reservoir fluid pressure, limit the application of experimental data, and restrict the in-depth development of stress-sensitive features. Achieve the effect of clear test principle and simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

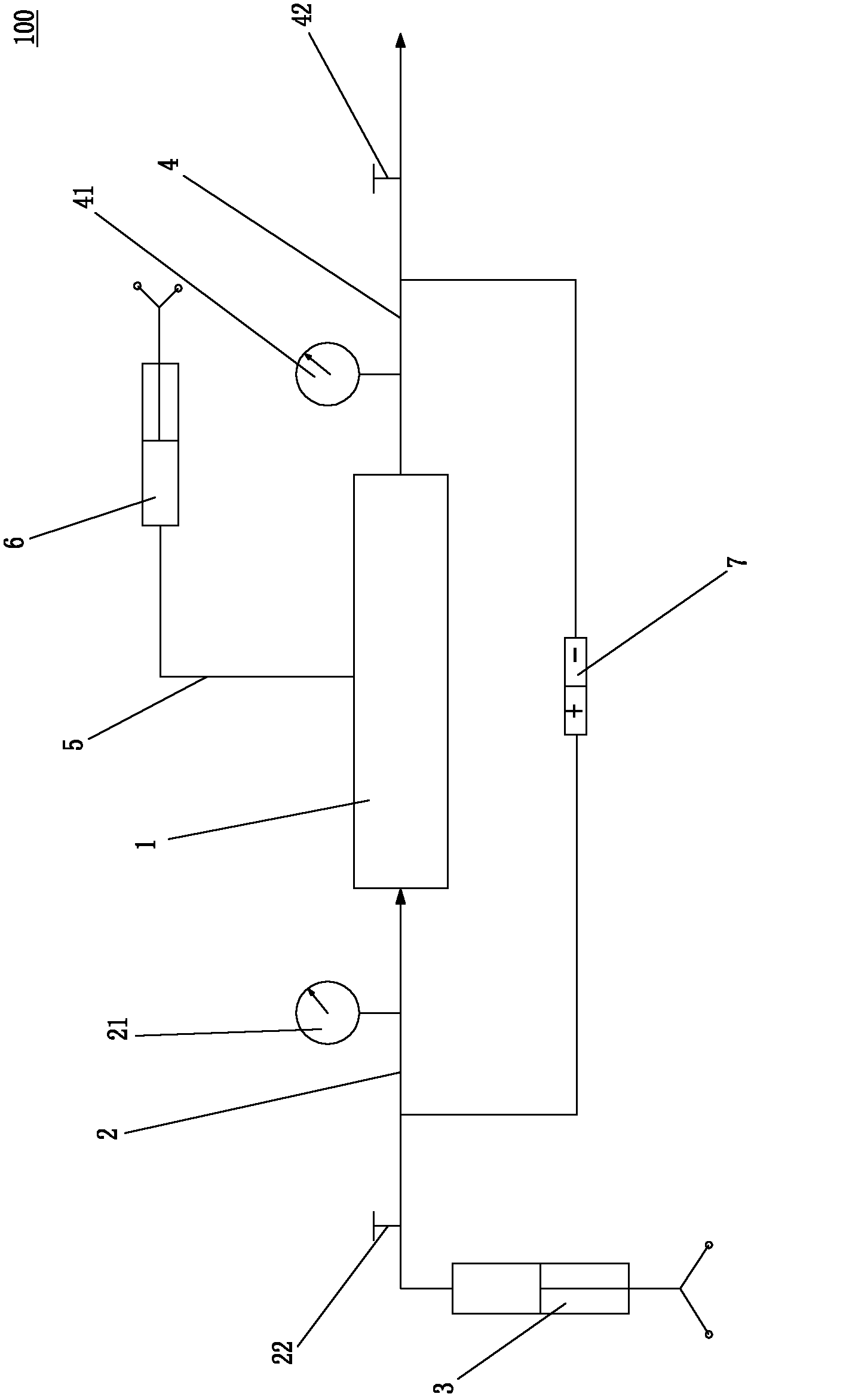

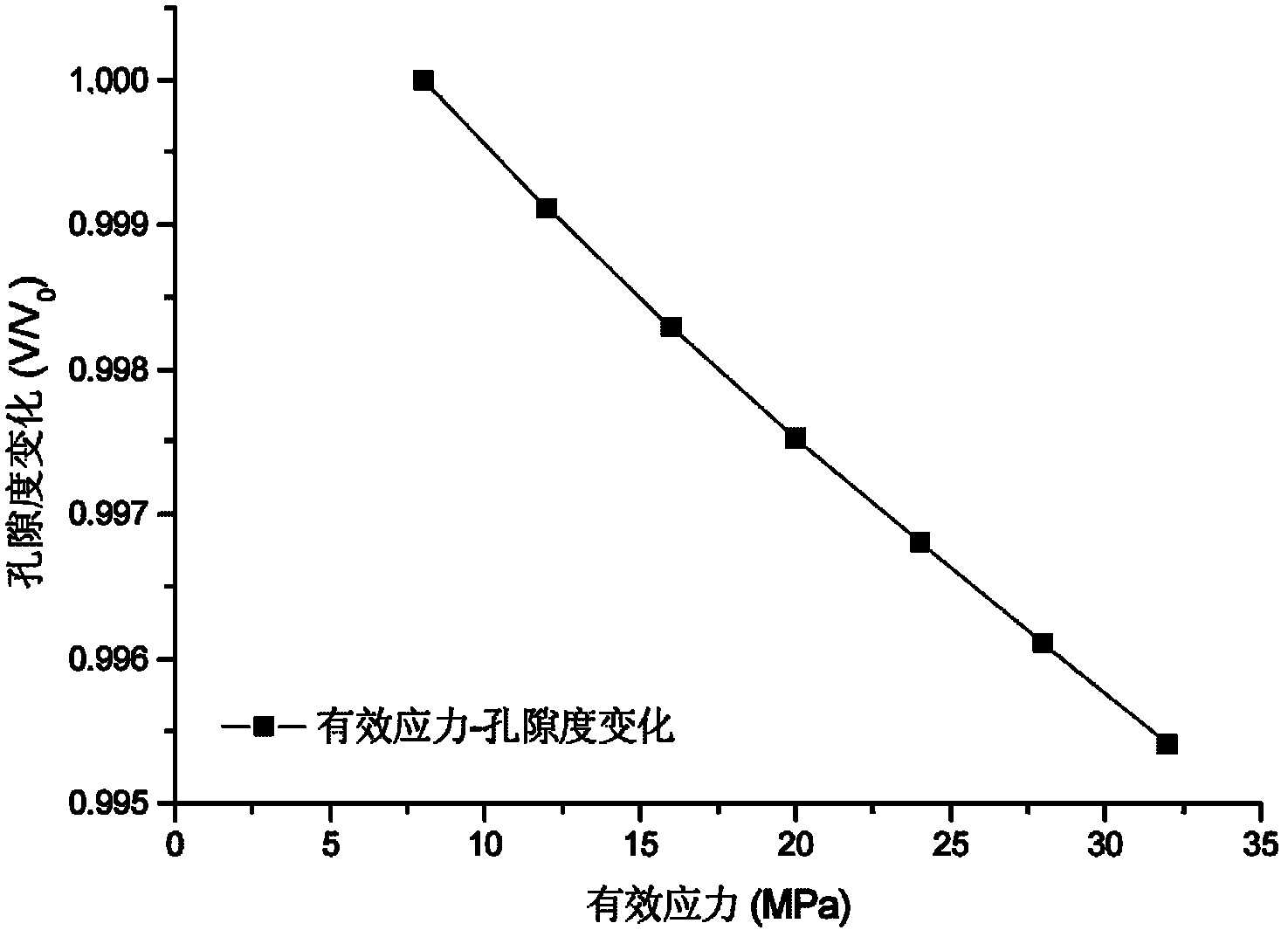

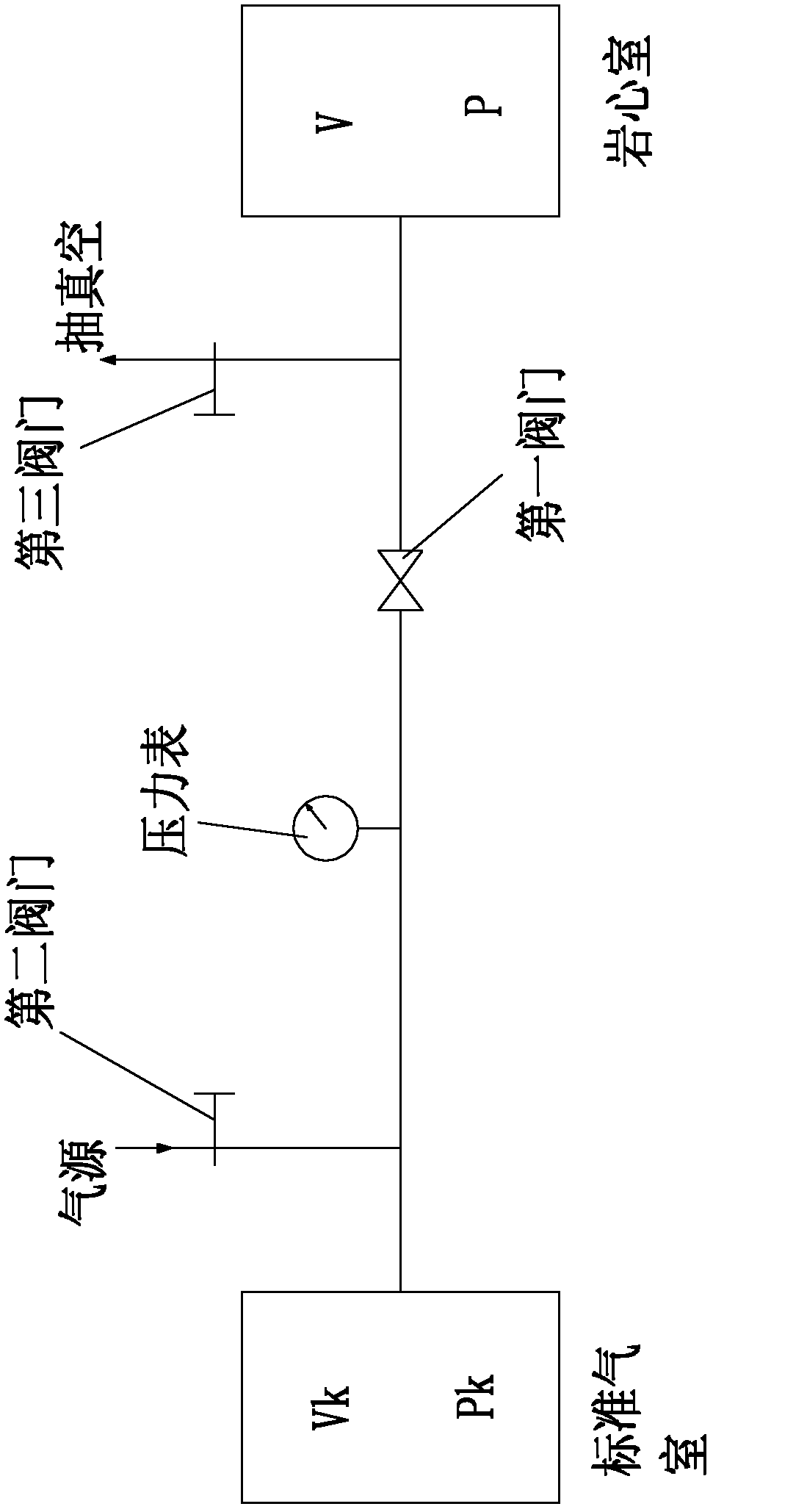

[0030] The present invention proposes a method for measuring overburden porosity by water measurement in seepage mechanics experiments. Confining pressure is applied around a rock core with a known pore volume, and a single-phase fluid with a known compressibility coefficient is injected into the rock core in a saturated manner, and the core is made The pressure at both ends of the core is in line with the real situation of the formation; then the confining pressure is increased sequentially, and the change of the pore pressure inside the core after the increase of the confining pressure is sequentially measured, so as to determine the pore volume change value, and then determine the porosity change under the overburden pressure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com