Microelectronic acceleration sensor and manufacturing process thereof

A technology of acceleration sensor and preparation process, which is applied in the direction of measurement of acceleration, speed/acceleration/shock measurement, metal material coating technology, etc., and can solve the problem of inability to realize multi-threshold latch and threshold reading, and difficulty in improving chip performance and stability , complex sensor processing technology and other issues, to achieve the effect of realizing single-chip intelligence, simple and reliable process steps, and reducing size and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

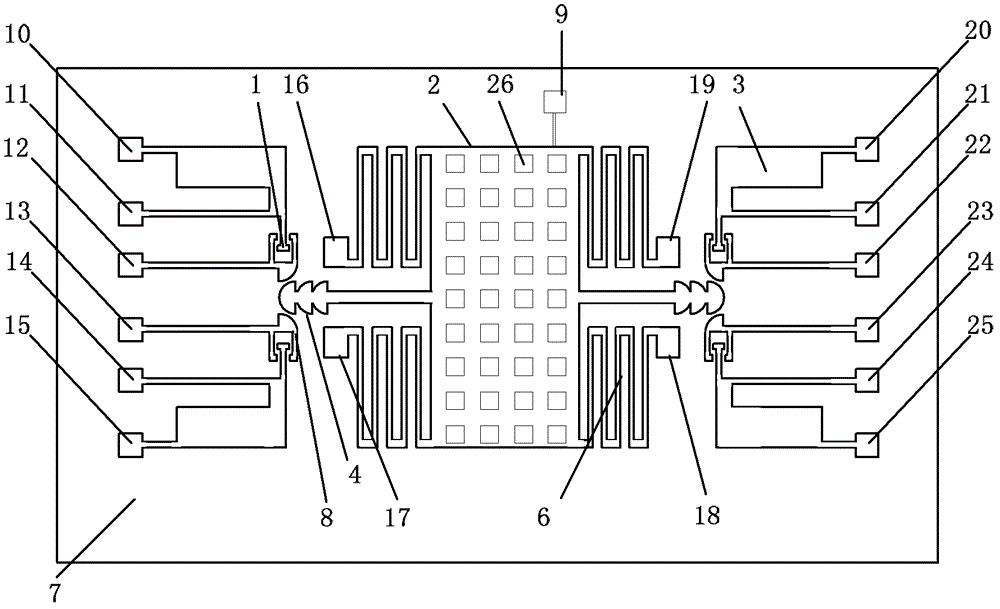

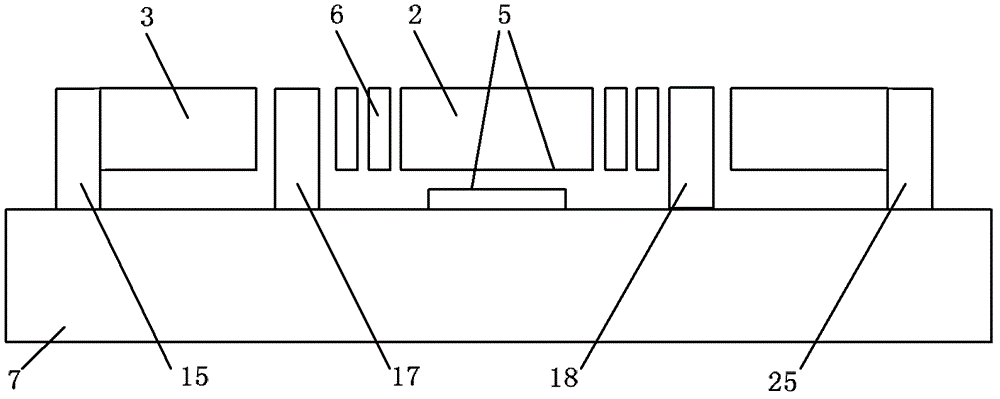

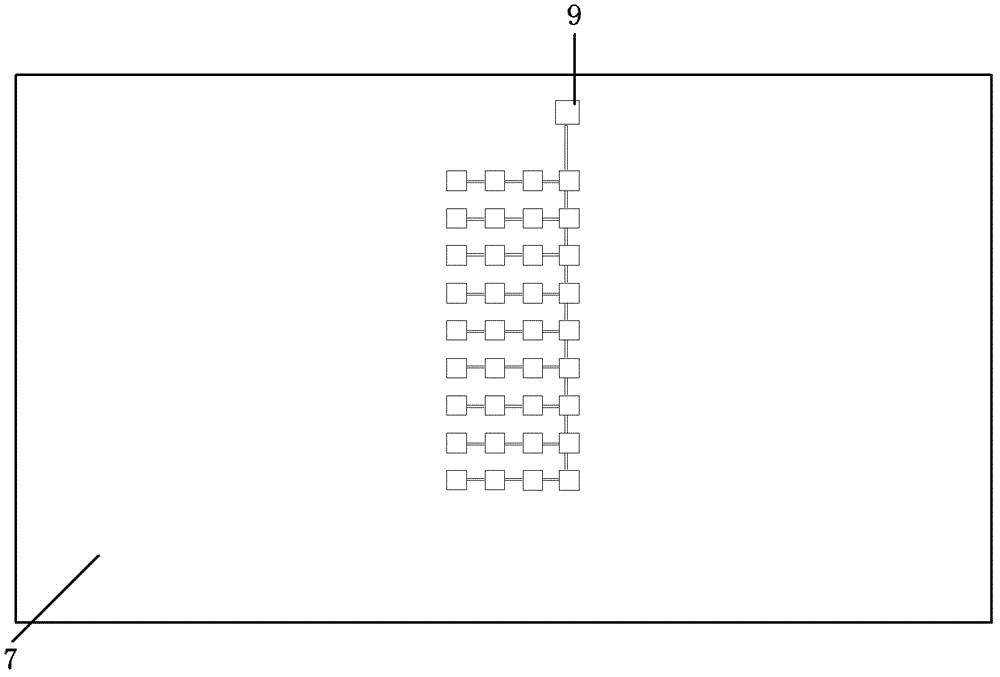

[0010] see figure 1 , 2 3, take the glass substrate 7 as the chip substrate, and set a single crystal silicon mass block 2 with a distance from the upper surface of the glass substrate 7 in the upper center of the upper surface of the glass substrate 7. There are square through holes 26 spaced apart and arranged in a rectangular array between the upper and lower surfaces of the mass block. Two monocrystalline silicon folding beams 6 are arranged symmetrically on the left and right sides, and the two monocrystalline silicon folding beams 6 on each side are symmetrically arranged on the upper and lower sides of the horizontal center line of the mass block, and one end of each monocrystalline silicon folding beam is respectively The suspension corresponds to the four symmetrical angles connecting the left and right of the mass block, and the other end of each single crystal silicon folded beam is respectively suspended and connected to the left and right two monocrystalline sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com