Kilowatt-level high power pulse Nd:YAG (neodymium-neodymium aluminum garnet) laser with one-level resonance and two-level amplification

A YAG laser, high-power technology, applied in the field of lasers, can solve the problem of insufficient beam quality and achieve significant economic and social benefits, stable power, and high beam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

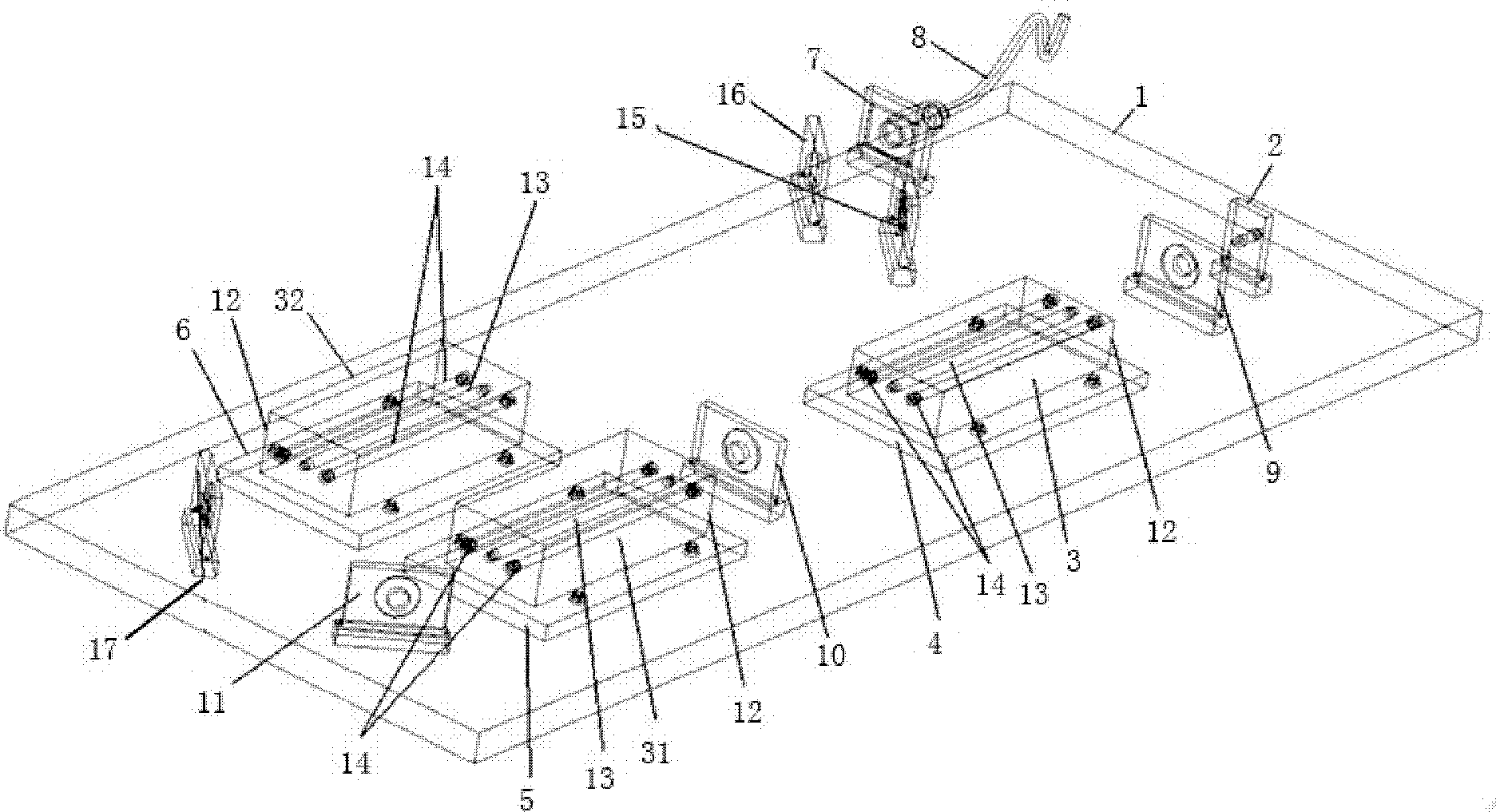

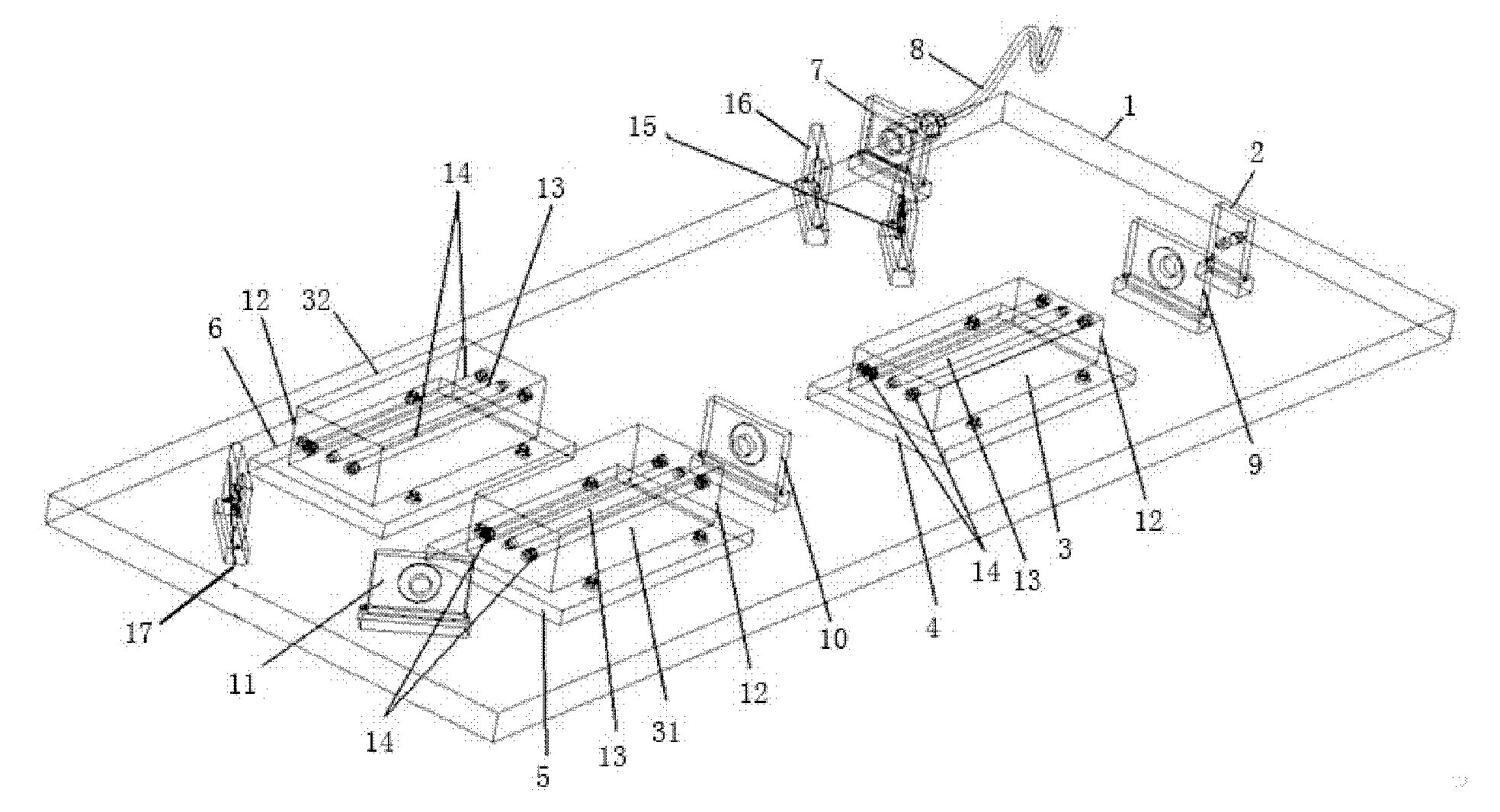

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 The structure shown is a kilowatt-level high-power pulsed Nd:YAG laser with one-stage resonance and two-stage amplification according to Embodiment 1 of the present invention. It adopts a three-stage MOPA system structure with one-stage resonance and two-stage amplification and an optical fiber flexible output mode. It includes a laser collimation system 2, a resonant stage 4, a primary amplifier stage 5, a secondary amplifier stage 6 and a flexible output system respectively installed on the base 1, and the primary amplifier stage 5 is located on the centerline of the output end of the resonant stage 4 Above; the secondary amplification stage 6 is located on one side of the primary amplification stage 5, and is parallel to the primary amplification stage 5; the flexible output system is located at the output end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com