Patents

Literature

44 results about "Laser chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser chemical fabrication of nanostructures

InactiveUS6864190B2Easy to operateBig and deep poreLayered productsSemiconductor/solid-state device manufacturingNd:YAG laserNanostructure

Disclosed is a process for fabricating luminescent porous material, the process comprising pre-treating a substrate (e.g. crystalline silicon) with laser radiation (e.g from a Nd:YAG laser) in a predetermined pattern followed by exposing the irradiated substrate to a chemical stain etchant (e.g. HF:HNO3:H2O) to produce a luminescent nanoporous material. Luminescent porous material having a luminescence maximum greater than about 2100 meV may be produced by this method. Such nanoporous materials are useful in optoelectronic and other semiconductor devices.

Owner:NAT RES COUNCIL OF CANADA

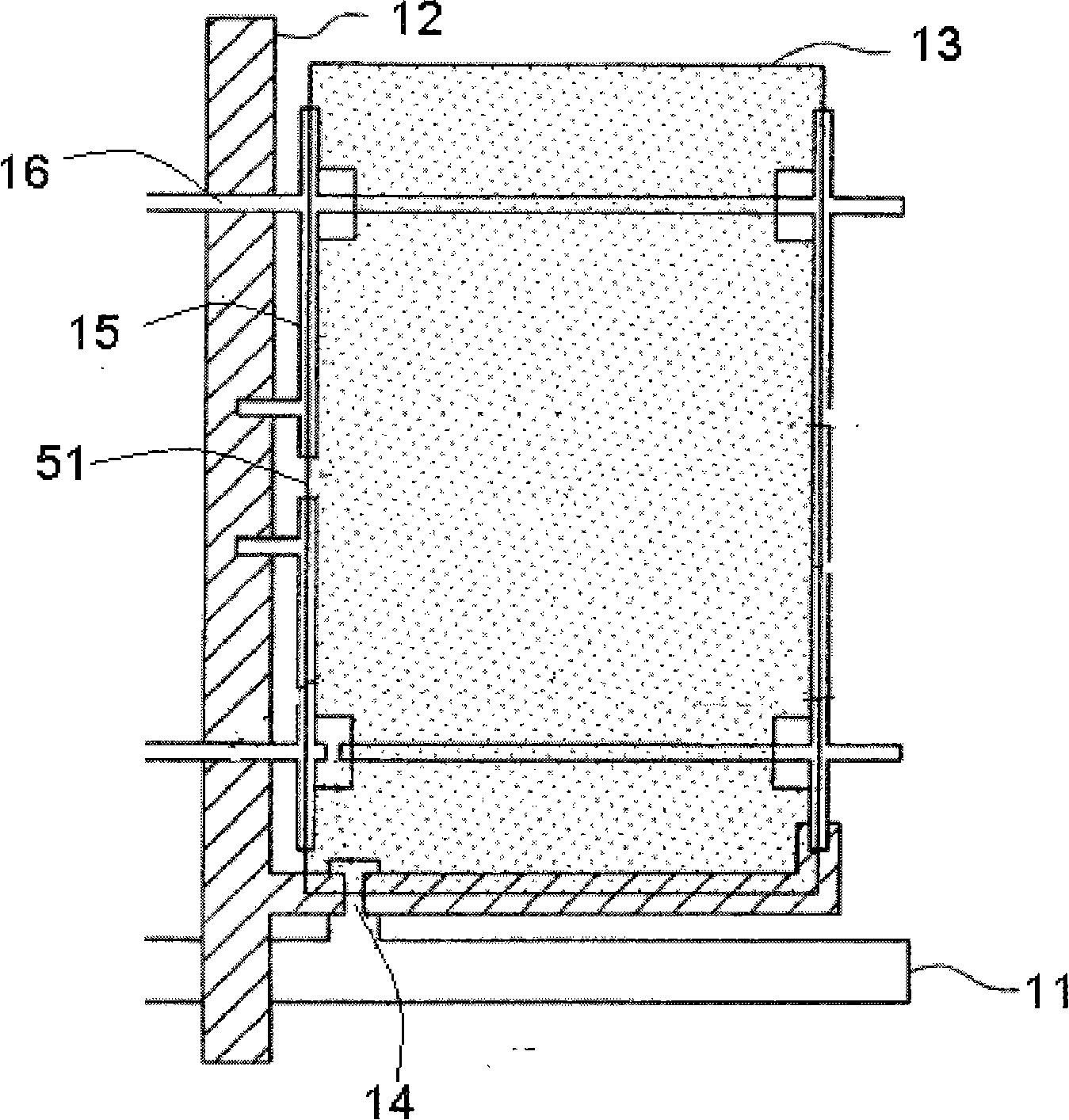

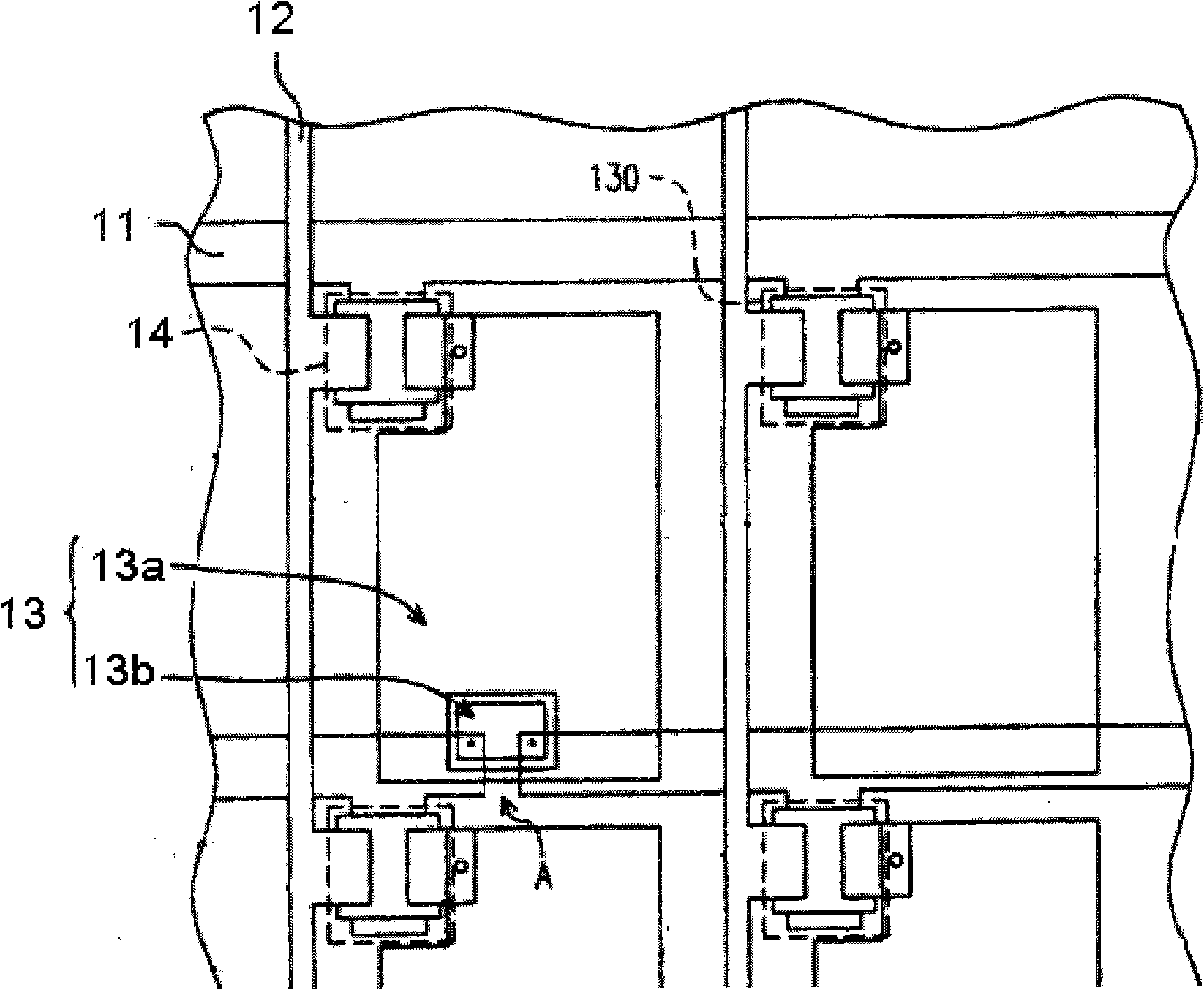

Liquid crystal display array base plate and patching method thereof

ActiveCN101776808AAvoid scrappingRepair Line DefectsSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayDisplay device

The invention provides a a patching method of a liquid crystal display array base plate. The patching method comprises the following patching flow processes: firstly, providing the liquid crystal display array base plate; then, detecting a linear defect part and simultaneously determining the position of the linear defect; next, using laser light beams for removing baffle layers formed by extending the two adjacent ends of the linear defect to a common electrode line; then, using a laser chemical deposition method for depositing a connection metal layer on the baffle layer removing position; finally, cutting off the adjacent external end electric connection part of the baffle layer on the common electrode line through laser light beams; and then, making a signal transmission line of the linear defect be able to complete the signal transmission through the common electrode line section. Thereby, the restoration method can effectively restore the defect of the signal transmission line on the original design, and the generation of other adverse defects caused by design modification can be avoided.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

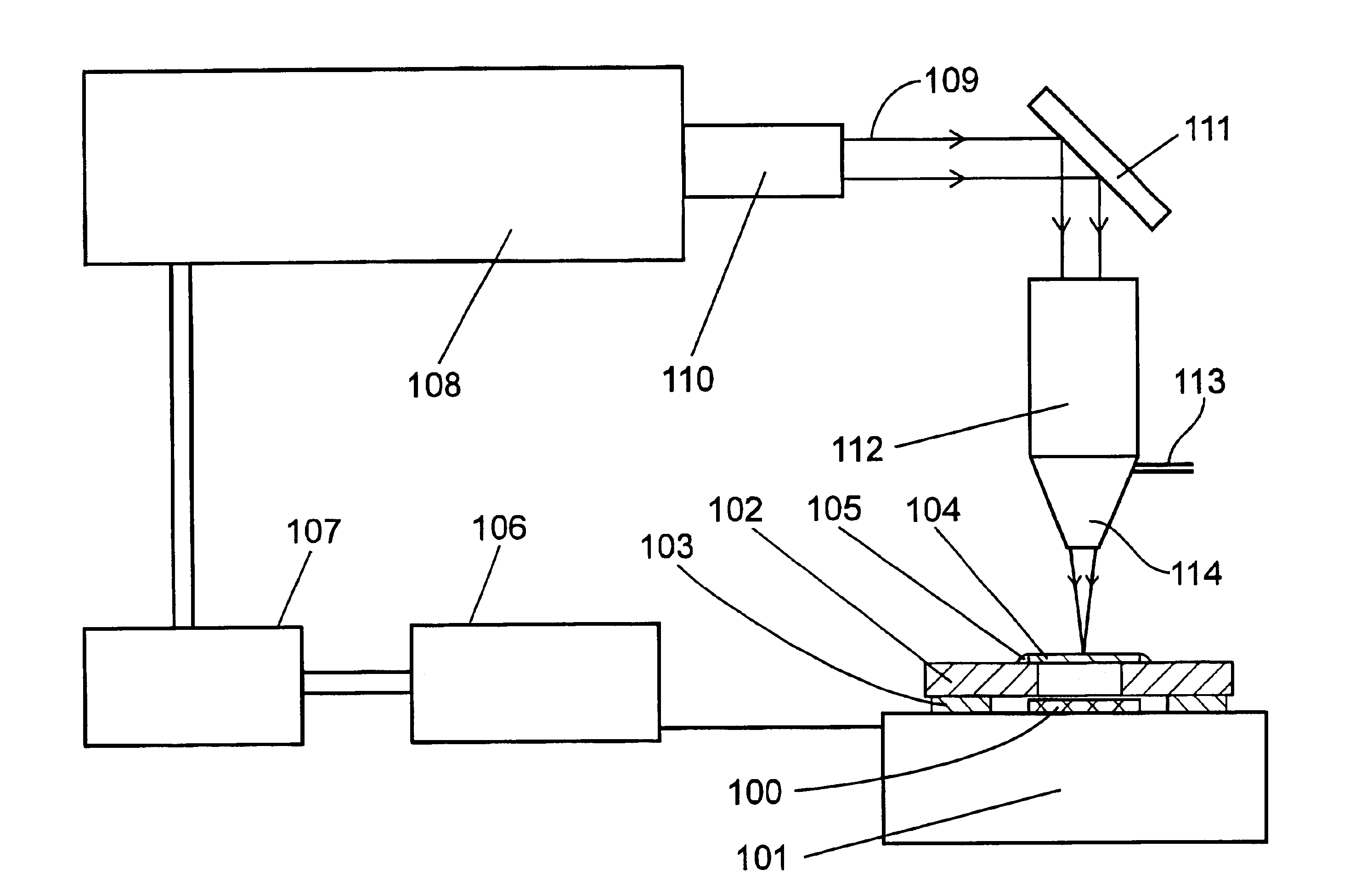

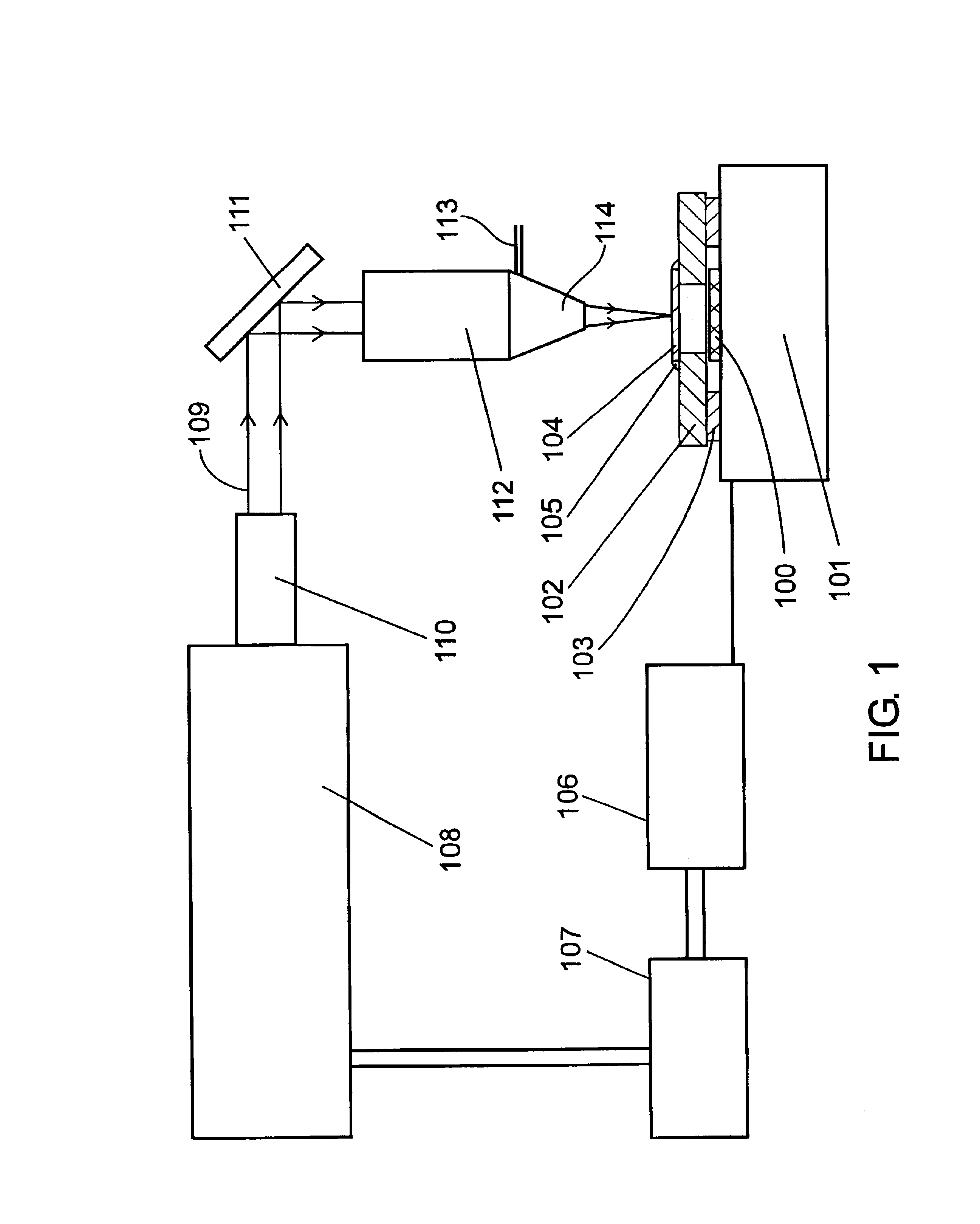

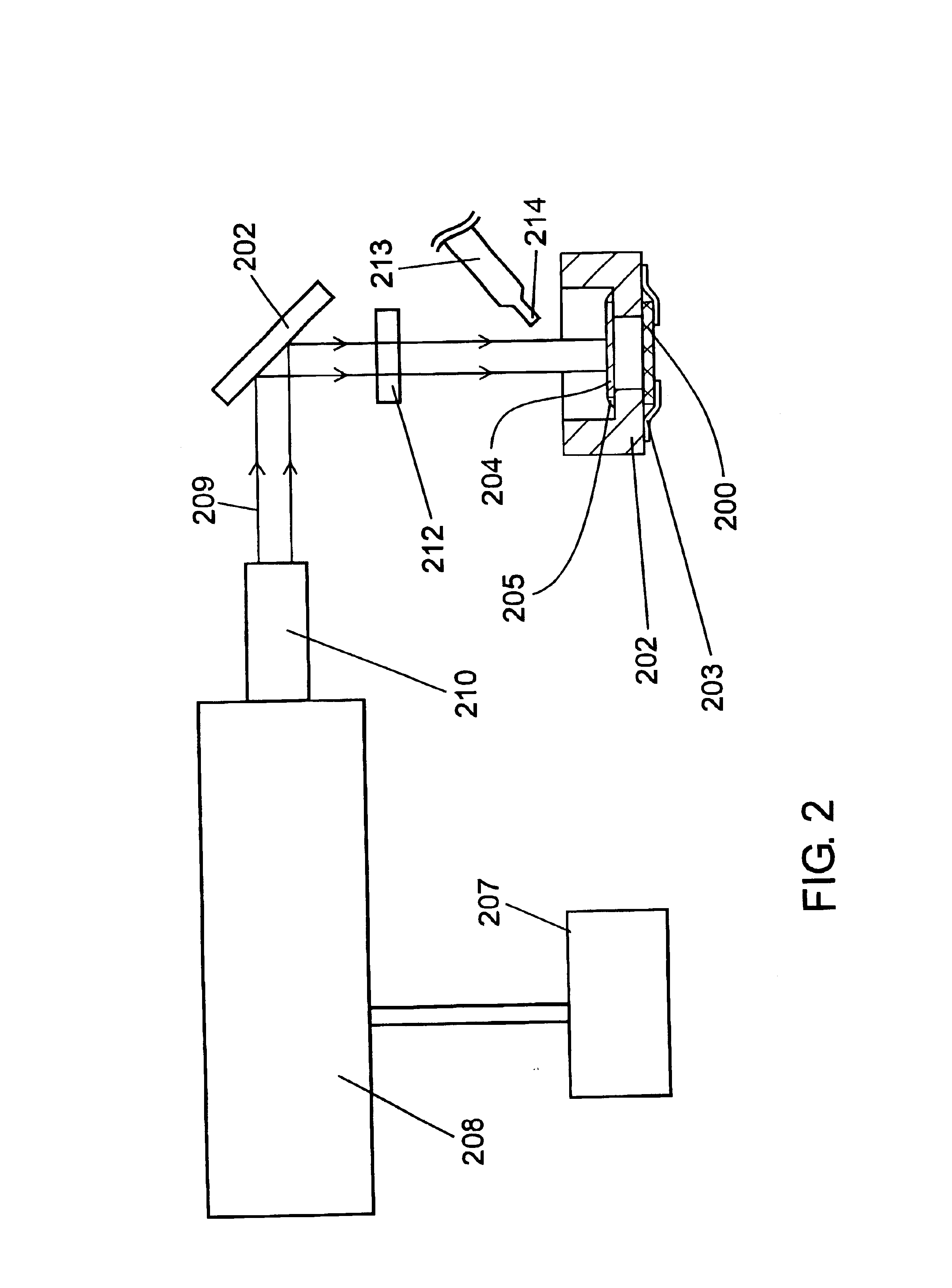

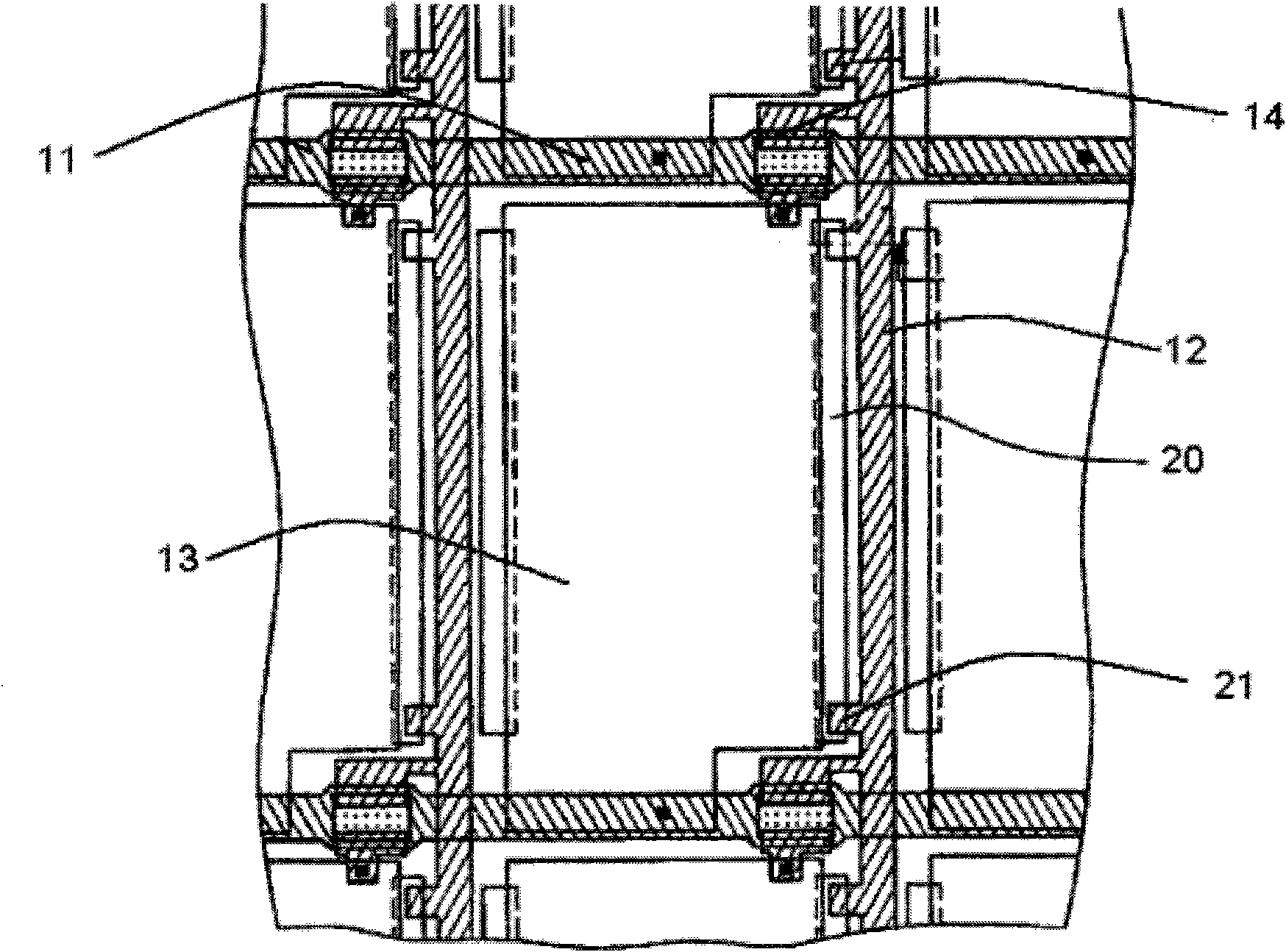

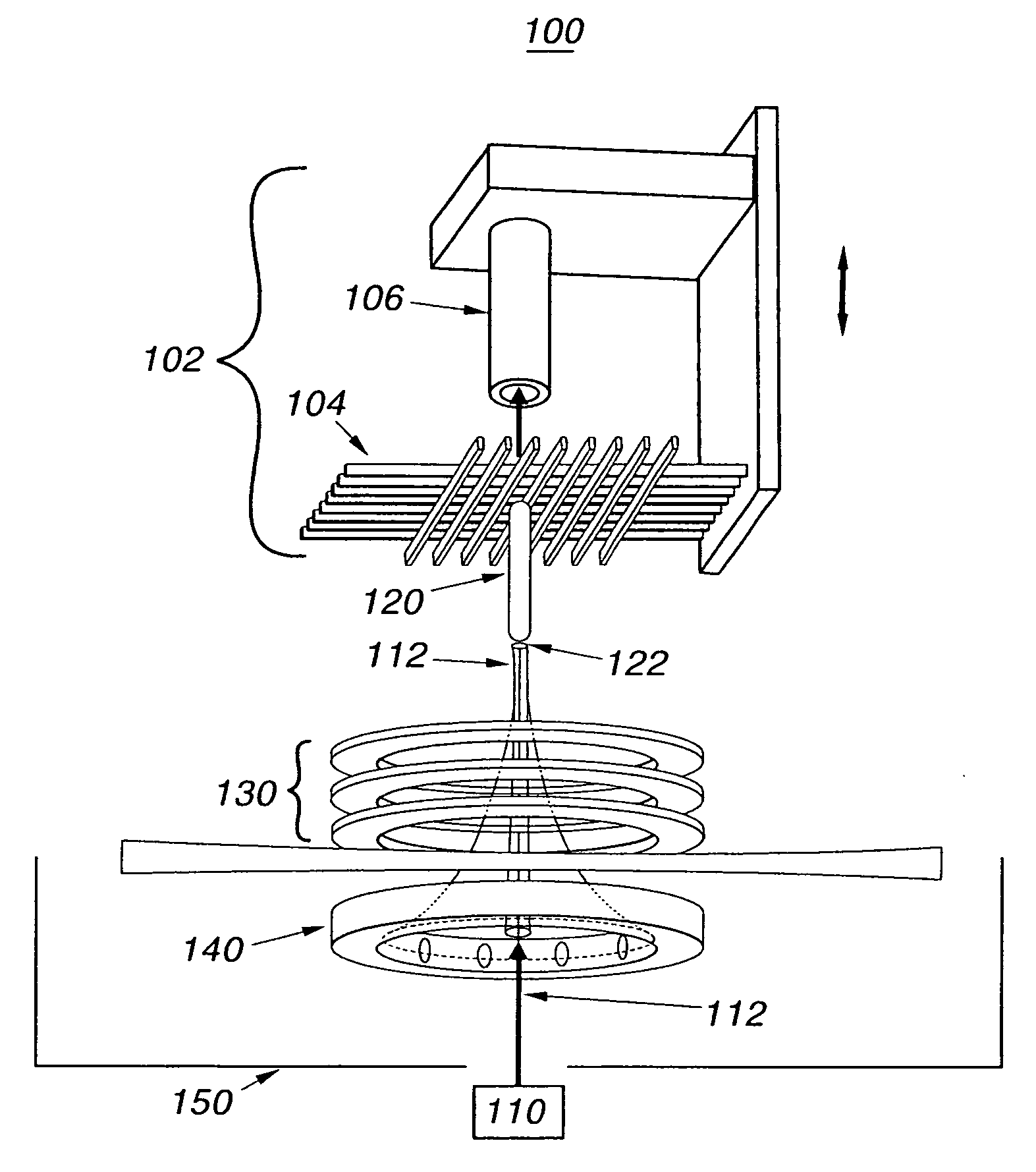

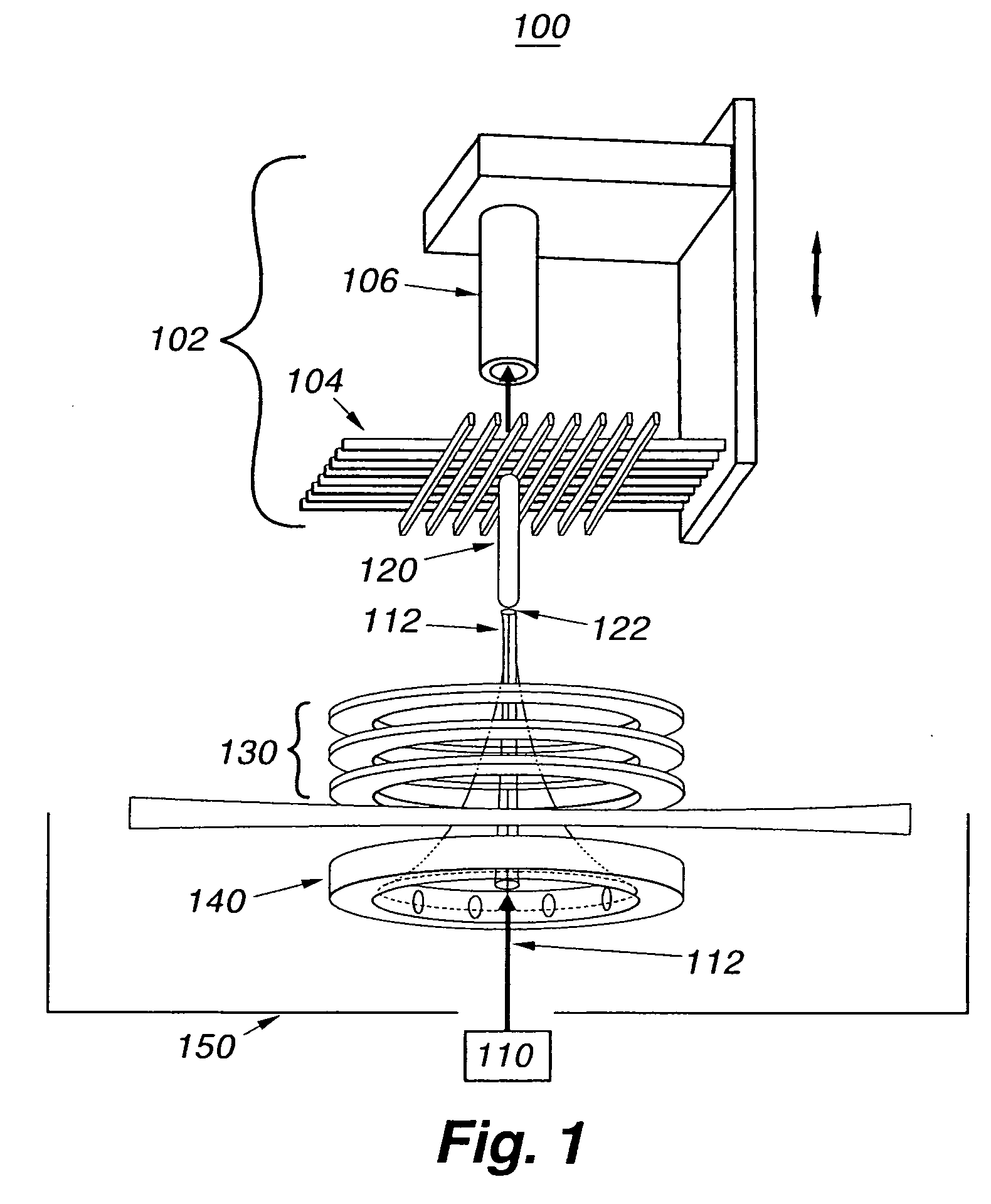

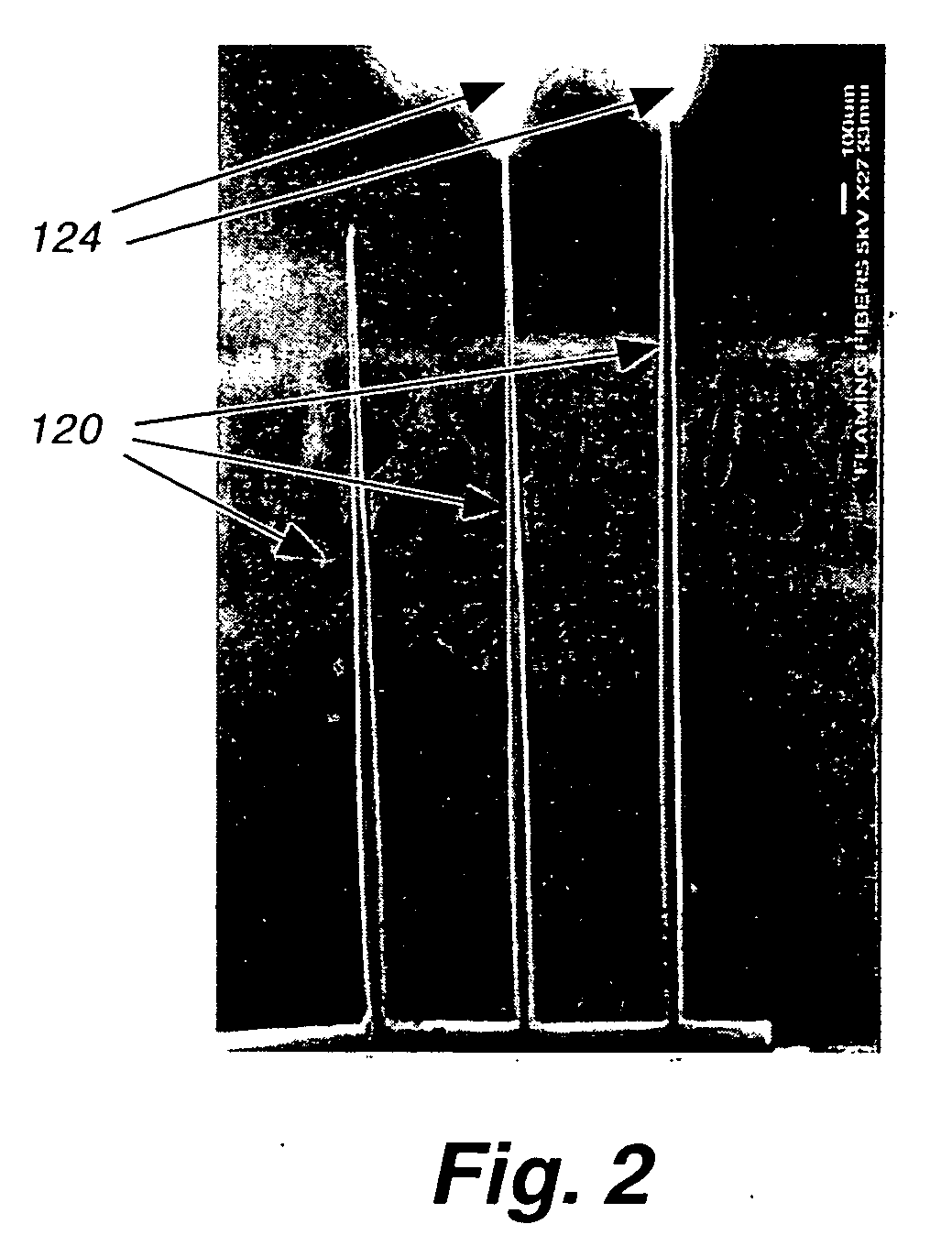

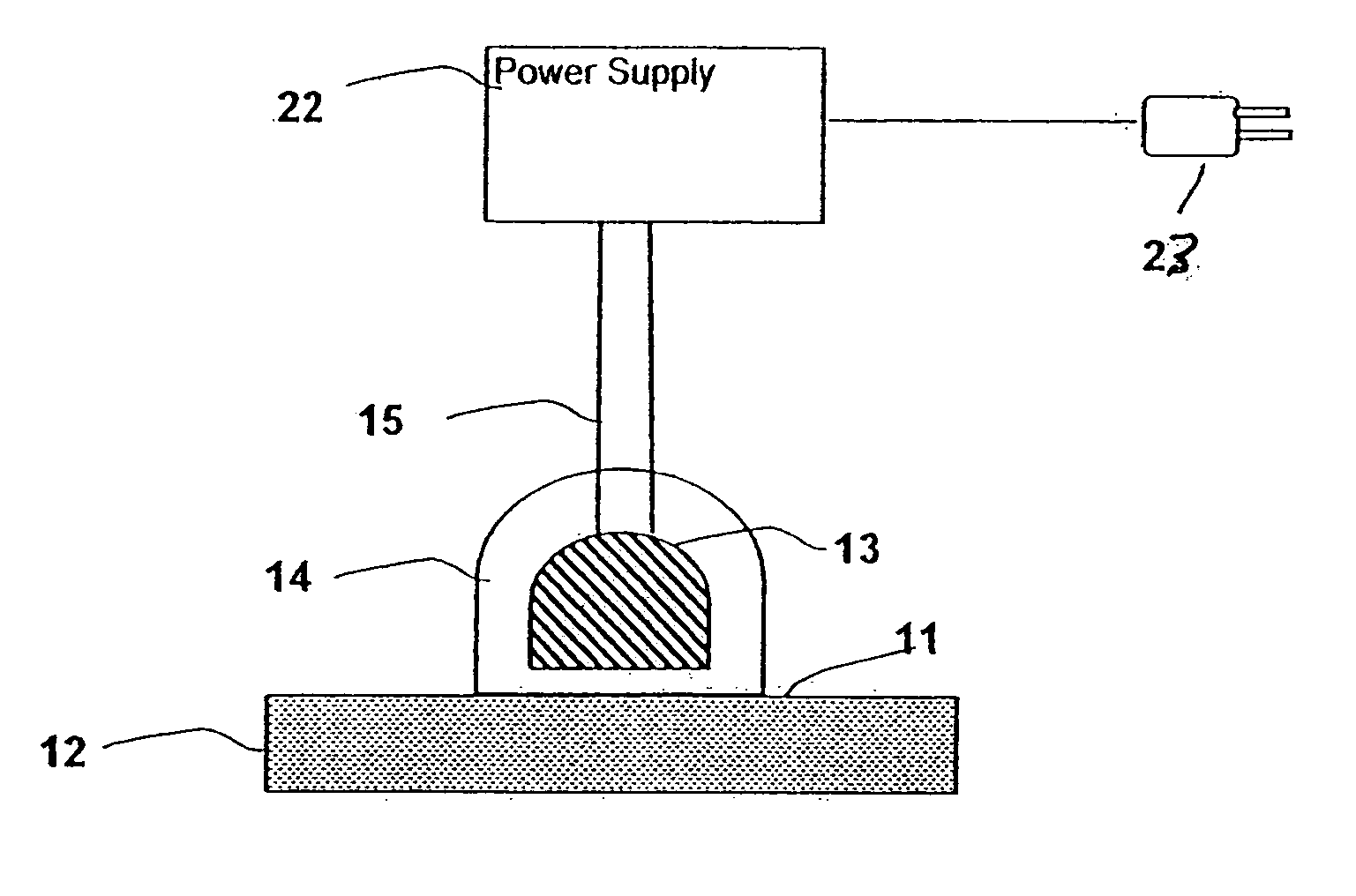

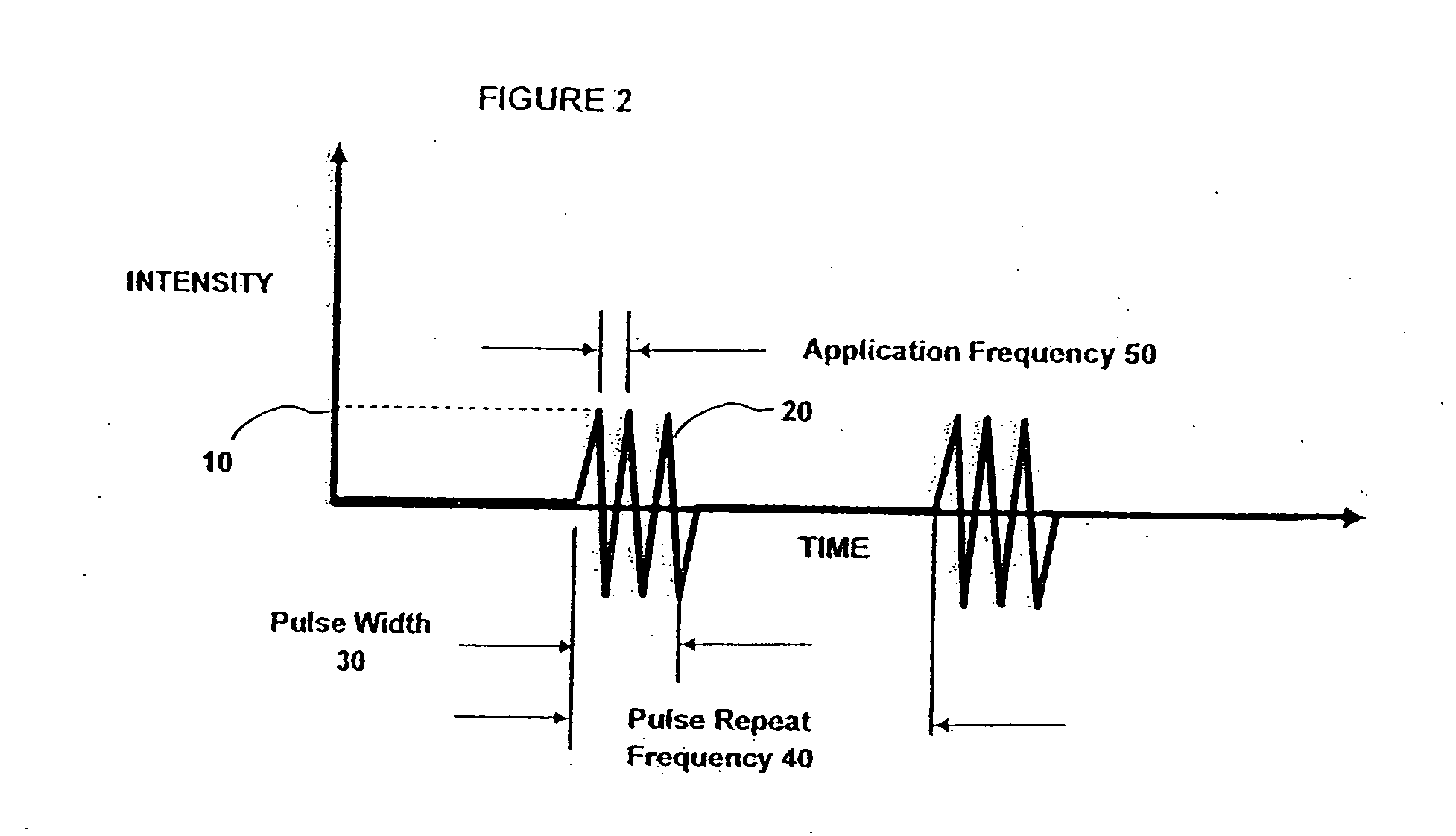

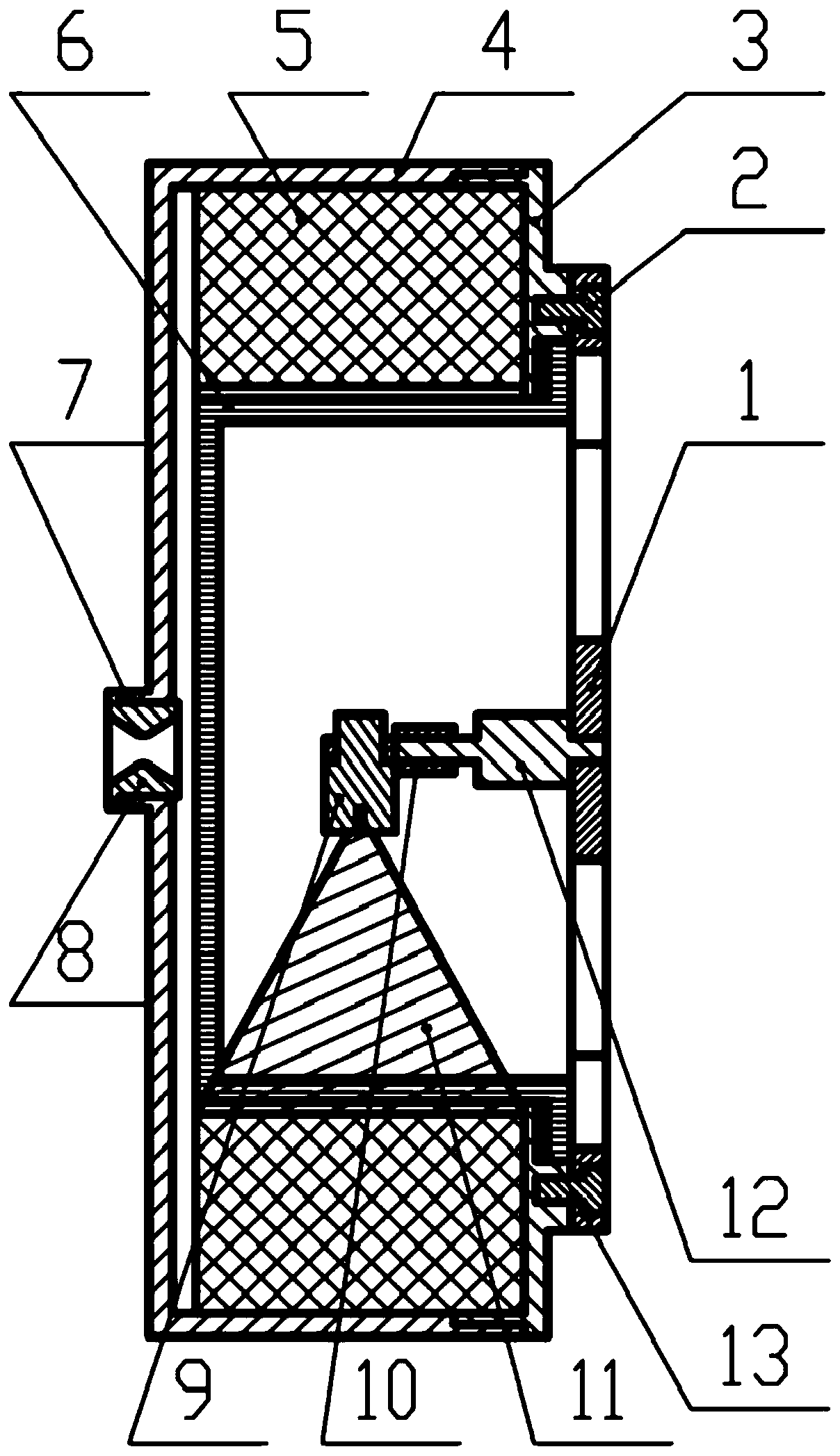

Method and apparatus for field-emission high-pressure-discharge laser chemical vapor deposition of free-standing structures

InactiveUS20060275537A1Simple structureIncrease ratingsChemical vapor deposition coatingFiberElectricity

A method of growing a free-standing structure, such as a fiber, rod, or tube. A laser beam having is focused on a terminal end of the fiber to heat the terminal end, and at least one gaseous precursor is provided into the beam. At least one electrode is located at a distance from the terminal end. The electrode is in electrical communication with the free-standing structure. A potential is applied between the terminal end and the at least one electrode. The applied potential creates a localized high pressure plasma in the vicinity of the terminal end, and generates reactive species from the gaseous precursor, and accelerates reactive species to the terminal end to grow the free-standing structure at an enhanced rate. An apparatus for growing fibers according to the method is also disclosed.

Owner:LOS ALAMOS NATIONAL SECURITY

Methods of diminishing permanent tissue markings and related apparatus

InactiveUS20080009774A1Efficient alterationDiminishment of permanent tissue markingsUltrasound therapyChiropractic devicesExcessive BleedingCombined use

A method of diminishing permanent tissue markings on a person caused by particles in the dermis includes applying ultrasound radiation to the tissue to generate cavitation bubbles and altering the tissue marking particles by collapse of the cavitation bubbles and transferring energy to the particles. The ultrasound radiation in one embodiment may have a frequency of about 15 KHz to 2 MHz and may be pulsed. The process may be repeated at the same location or other locations while resisting undesired, excessive bleeding of the dermis. The permanent tissue markings may be tattoos. The method may be used in conjunction with other methods of removing the permanent tissue markings, which may include laser, chemical agents, and biological agents. Related apparatus is enclosed.

Owner:UNIVERSITY OF PITTSBURGH

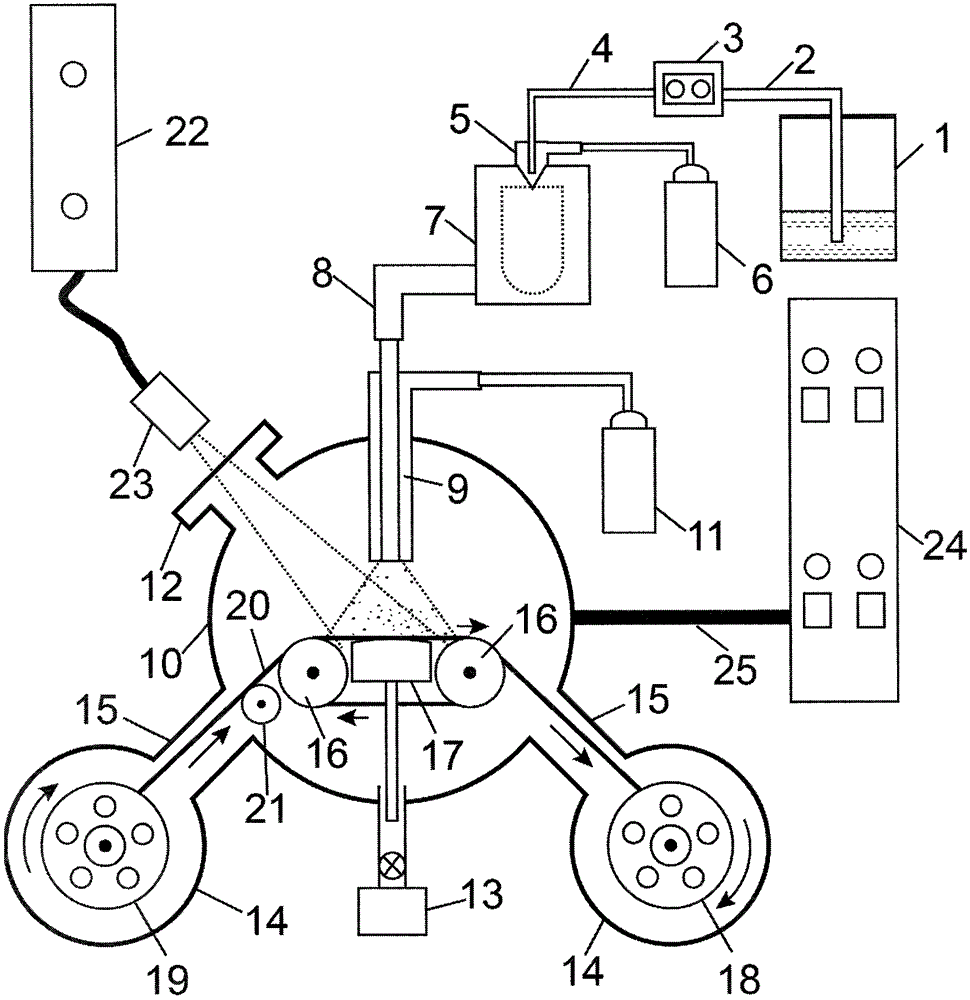

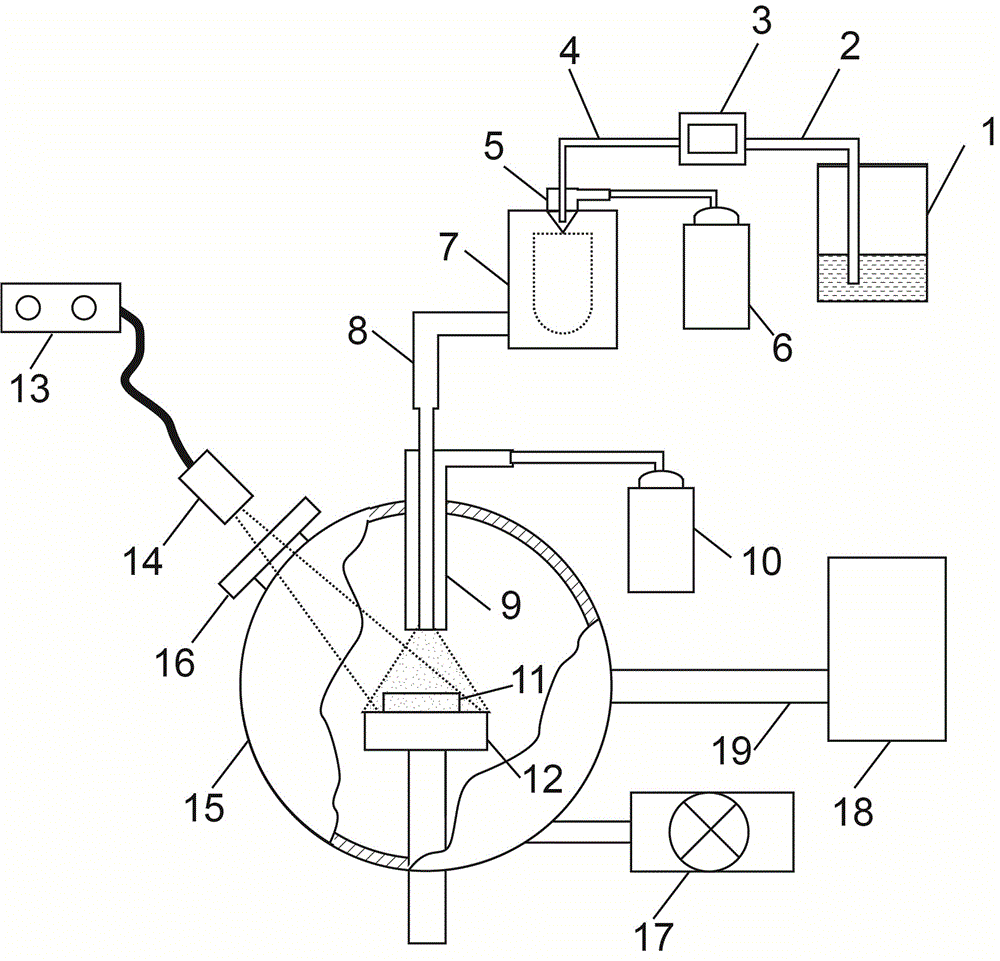

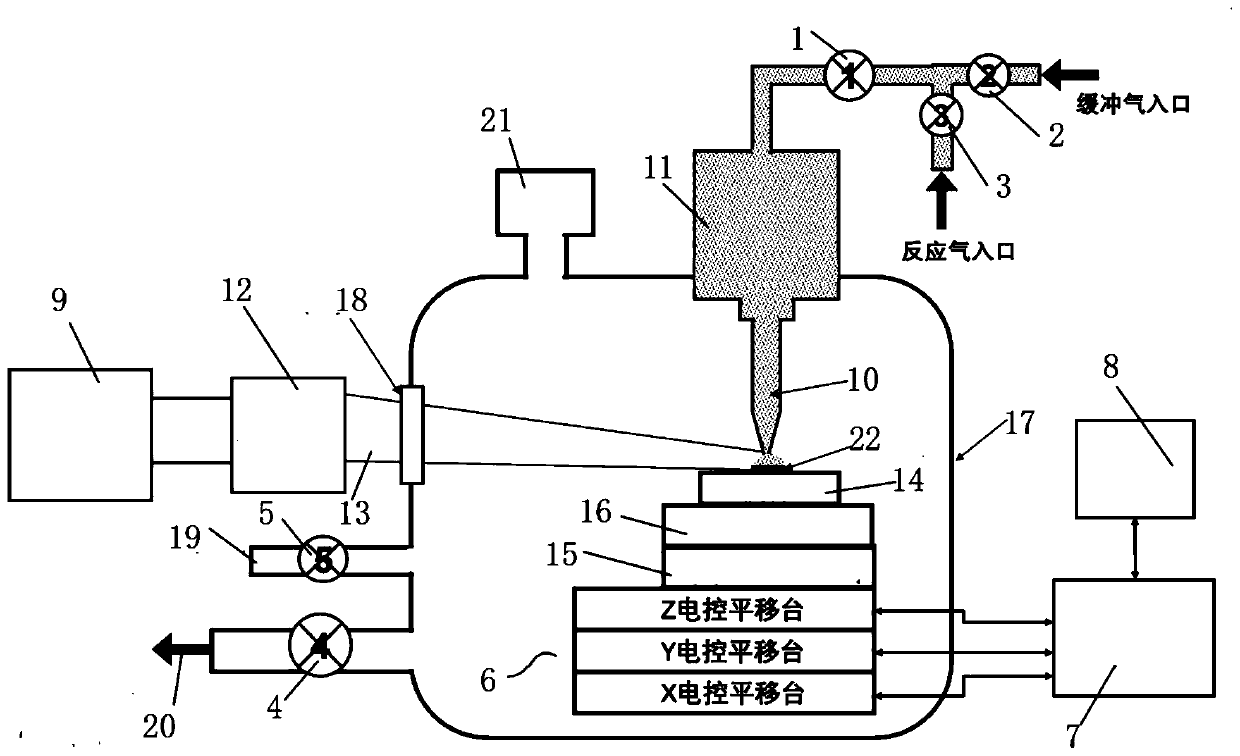

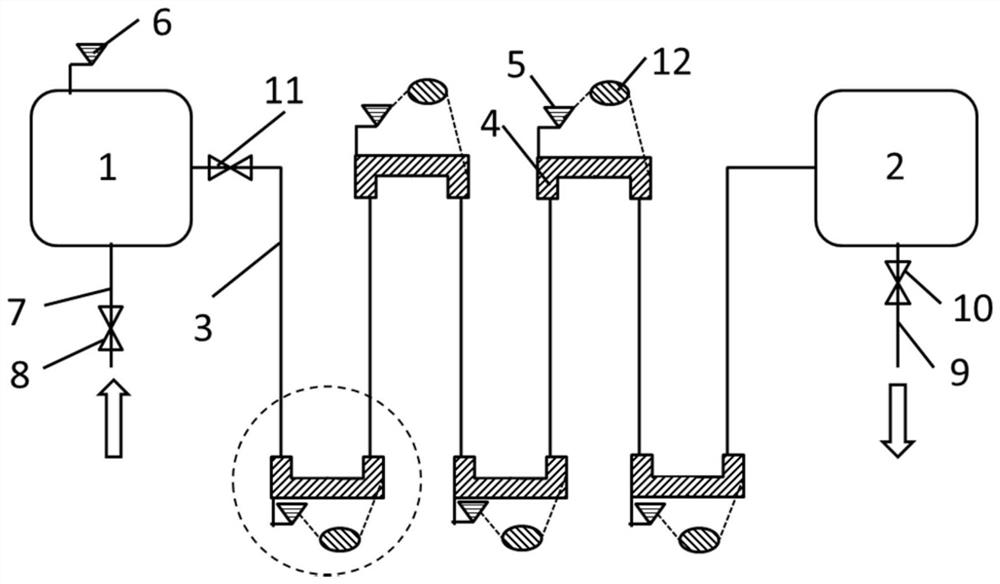

Technique and equipment for preparing high-temperature super-conduction strip materials by virtue of laser chemical vapor deposition method

The invention relates to a technique and equipment for rapidly and continuously preparing second-generation high-temperature super-conduction strip materials by virtue of a liquid injection atomization-multielement eutectoid laser chemical vapor deposition method. According to a liquid raw material supply system of the equipment, the problems that accurate, stable and continuous raw material steam cannot be supplied for a long time by virtue of a traditional chemical vapor deposition method, and components of a thin film cannot be accurately controlled in a preparation process of a multielement thin film are solved. Based on the liquid raw material supply system of the equipment, by illuminating the surface of a substrate by virtue of laser, the reaction activation energy among molecules of a gas phase raw material is substantially reduced, and the speed of the chemical reaction is increased. By virtue of a compound roller transmission system of the equipment, long flexible substrate strip materials can be gradually transported to a deposition region of a heating table, so as to rapidly and continuously prepare second-generation high-temperature super-conduction strip material products.

Owner:WUHAN XINGUI TECH QIANJIANG CO LTD

Laser chemical order controllable preparation method of monocrystalline silicon inverted pyramid suede

InactiveCN103426736ASimple manufacturing processEasy to operateSemiconductor/solid-state device manufacturingPicosecond laserLaser scanning

The invention discloses a laser chemical order controllable preparation method of a monocrystalline silicon inverted pyramid suede. The laser chemical order controllable preparation method comprises the following steps of 1 performing laser scanning, tapping and positioning, namely utilizing software to draw a required felting graph (computer aided design (CAD) drawing), performing the scanning and the tapping on the surface of a cleaned silicon wafer through picoseconds laser according to the graph to form a micron-sized inverted-cone-shaped suede with evenly-distributed holes; 2 performing acid washing of the poroid suede, firstly using hydrogen fluoride (HF) to perform the acid washing and then using distilled water to perform the washing; 3 performing acid washing of a poroid suede layer, firstly using the HF to perform acid washing and then using ultrapure water to perform washing; 4 preparing the inverted pyramid suede, namely placing a sample subjected to the acid washing into a prepared alkaline solution to perform heating in water bath so as to prepare the micron-sized inverted pyramid suede. A preparing and mask-removing process is omitted and replaced by a laser scanning and tapping technology, and the size and the shape of a felting region can be customized through the software (CAD). The monocrystalline silicon inverted pyramid suede has excellent reflection-reducing effect on a 400-700nm wave band with intensive solar spectrum photons, and the reflection rate reaches up to 5%.

Owner:BEIJING UNIV OF TECH

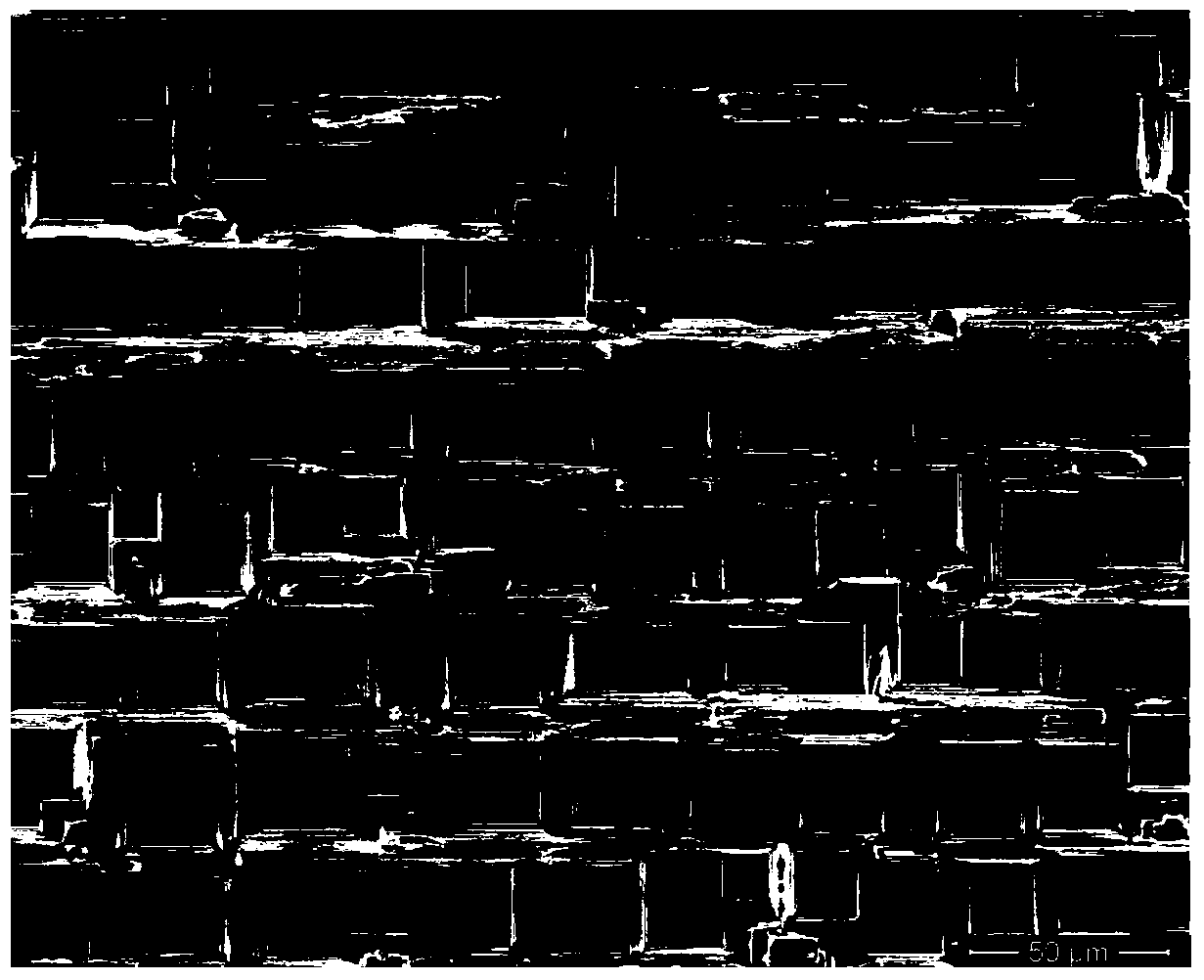

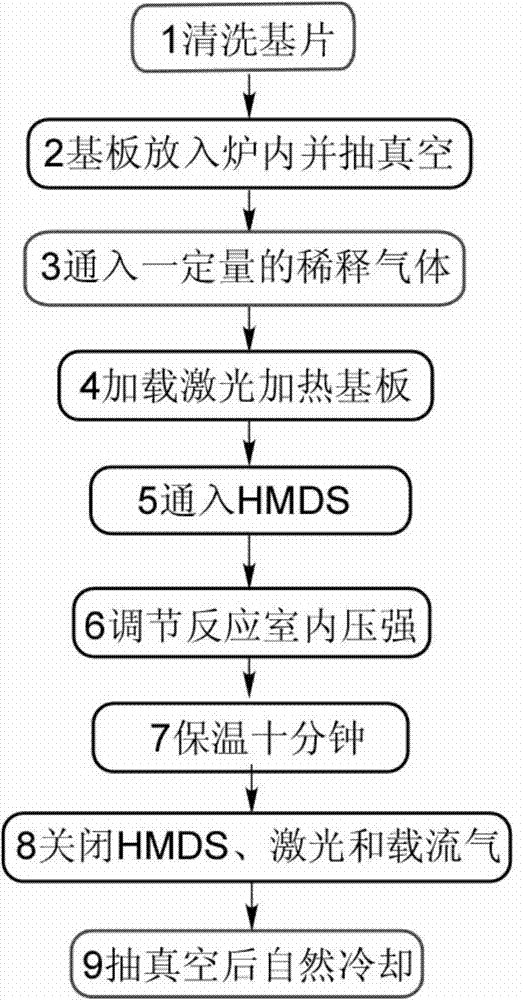

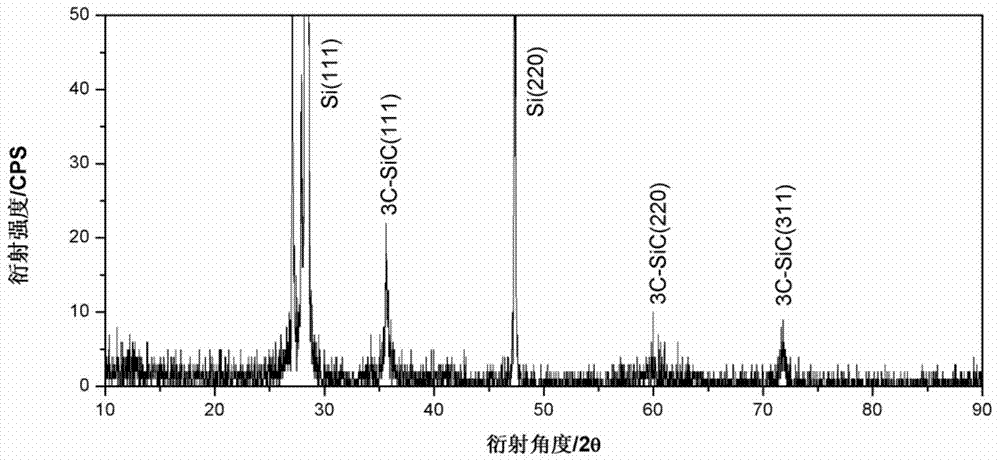

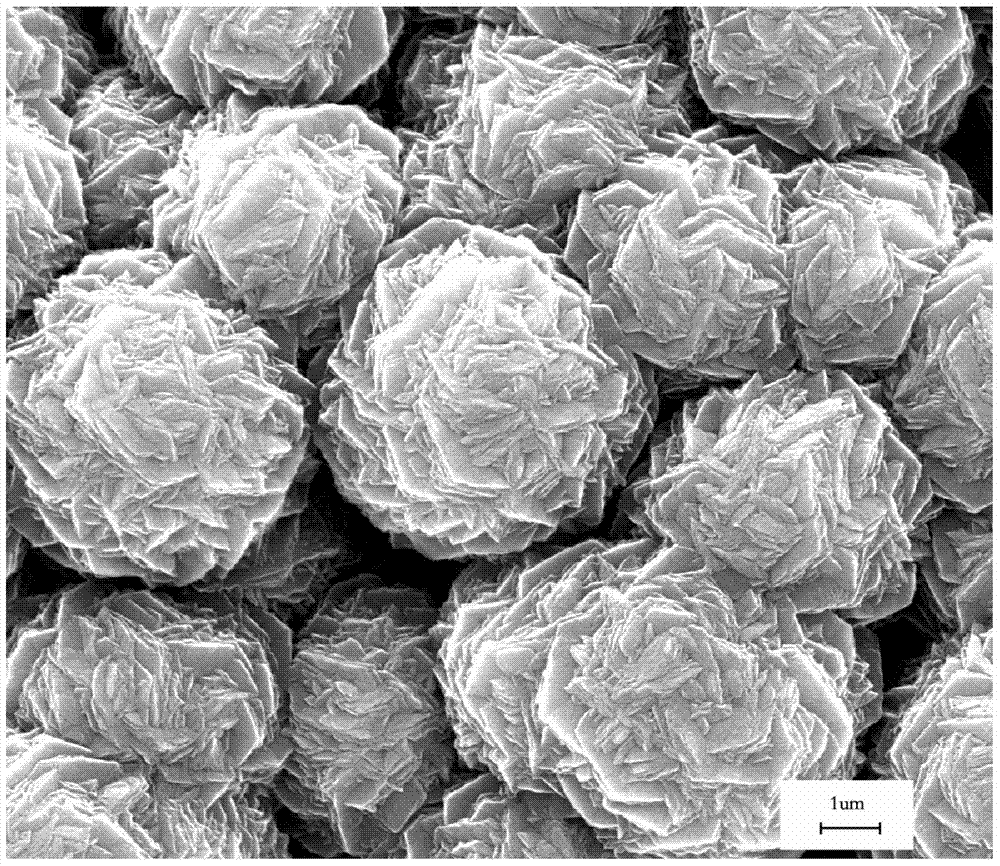

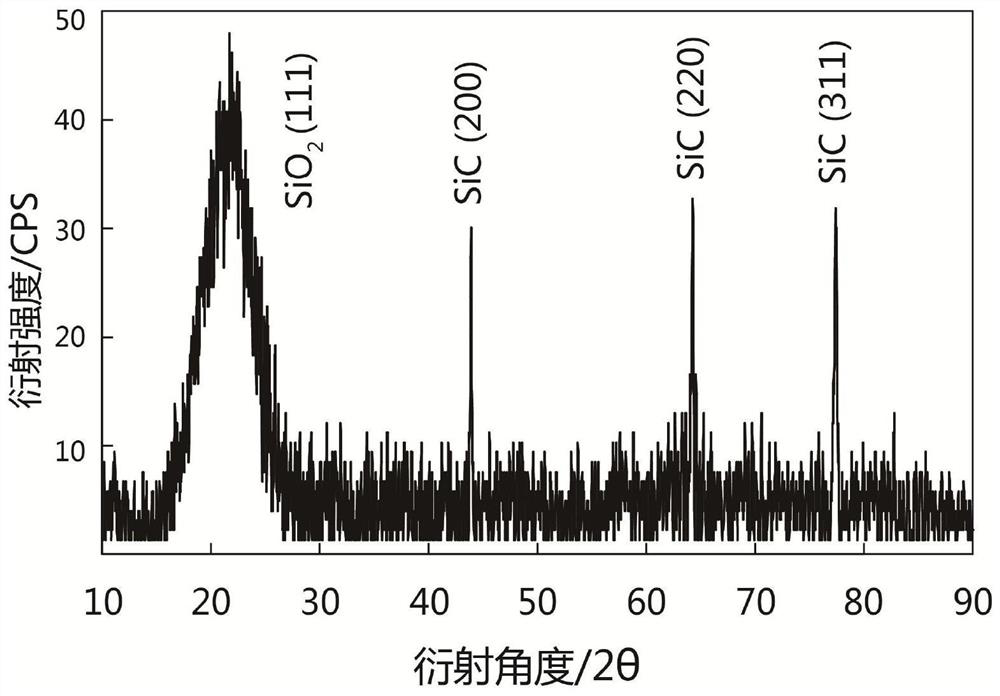

Preparation method of silicon carbide film

ActiveCN104498897ALarge specific surface areaRich Surface TopographyCatalyst carriersChemical vapor deposition coatingCubic silicon carbideGas phase

The invention relates to a preparation method of a cubic silicon carbide film, which comprises the following steps: putting a cleaned substrate onto a substrate seat of cold-wall laser chemical vapor deposition device, and vacuumizing; introducing a right amount of argon; starting the laser to radiate the substrate surface until the substrate temperature rises to the set temperature for depositing the silicon carbide film, and keeping the temperature stable; starting a current-carrying gas containing HMDS, adjusting the vacuum degree of the reaction chamber, and keeping for 5-30 minutes; and shutting down the current-carrying gas containing HMDS, shutting down the laser and diluting gas, vacuumizing, and naturally cooling to room temperature. The silicon carbide film has the advantages of higher specific area and abundant surface topography. Therefore, the catalyst can be attached to the silicon carbide support surface more easily, thereby enhancing the supporting capacity of the catalyst and the adhesive force of the support, prolonging the service life of the catalyst, increasing the contact area between the catalyst and reaction substance and enhancing the catalytic efficiency of the catalyst.

Owner:WUHAN UNIV OF TECH

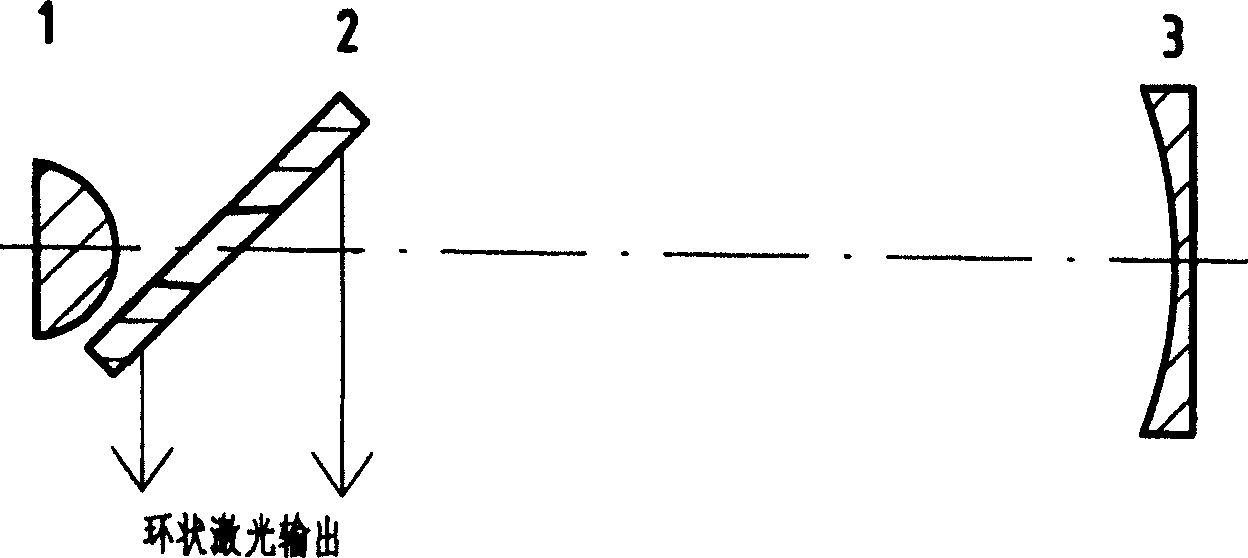

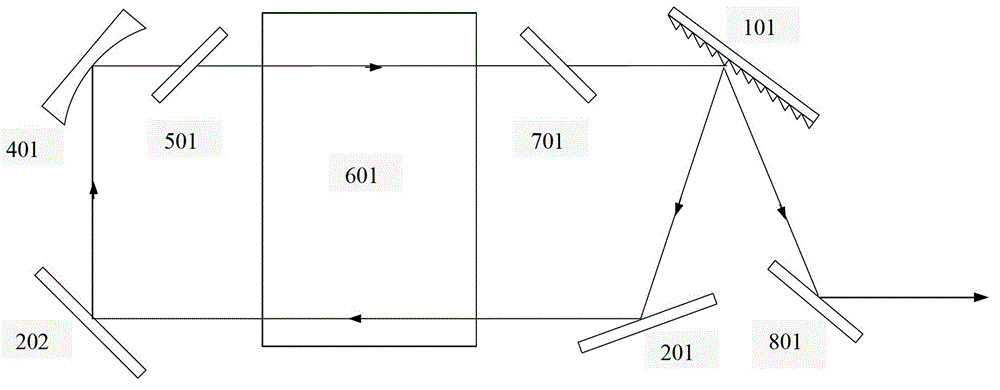

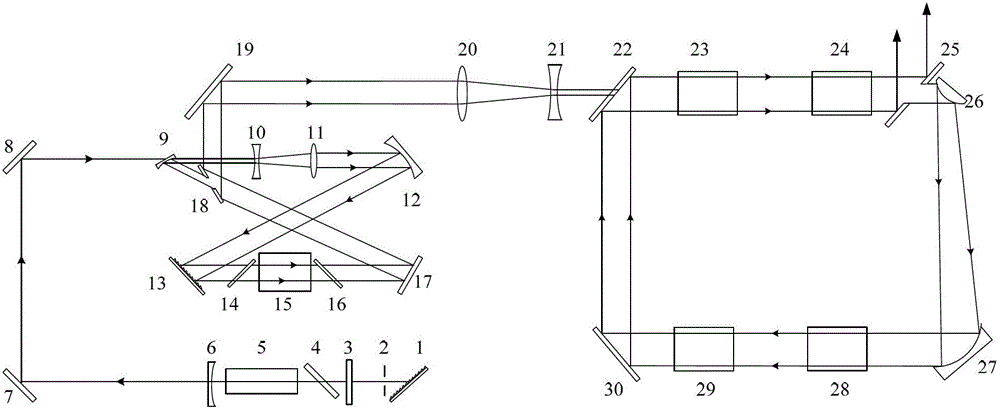

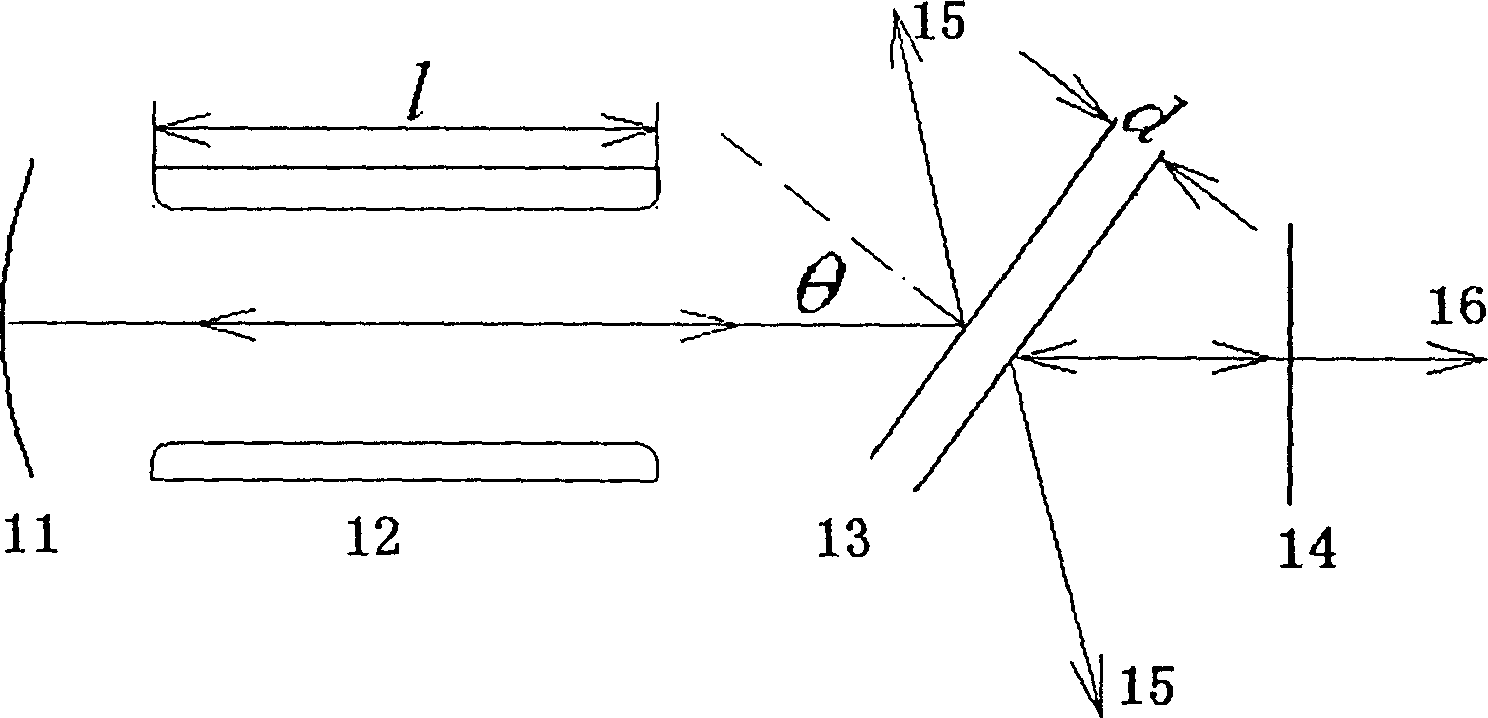

Unstable laser cavity tunned by grating

InactiveCN1761110ALow cavity lossHigh energy laserOptical resonator shape and constructionLow dissipationHydrogen fluoride

The invention is suitable to tuning unstable laser cavity in high power through grating. The laser cavity is composed of convex spherical reflector, concave spherical reflector with center hole and composite converging optical system of grating behind the concave spherical reflector. The convex spherical reflector, the concave spherical reflector and the composite converging optical system of grating are aligned along a common optical axis. There is a Littrow angle between normal of grating and optical axis. The grating is a reflecting concave spherical diffraction grating or reflecting plane diffraction grating. Advantages are: low dissipation of laser cavity, high output laser energy and laser power. The invention is applicable to multiple turnable lasers including carbon dioxide laser, carbon monoxide laser, hydrogen fluoride / deuterium fluoride laser etc. There is wide applied foreground in areas of laser chemistry, processing and radar, and atmospheric propagation etc.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

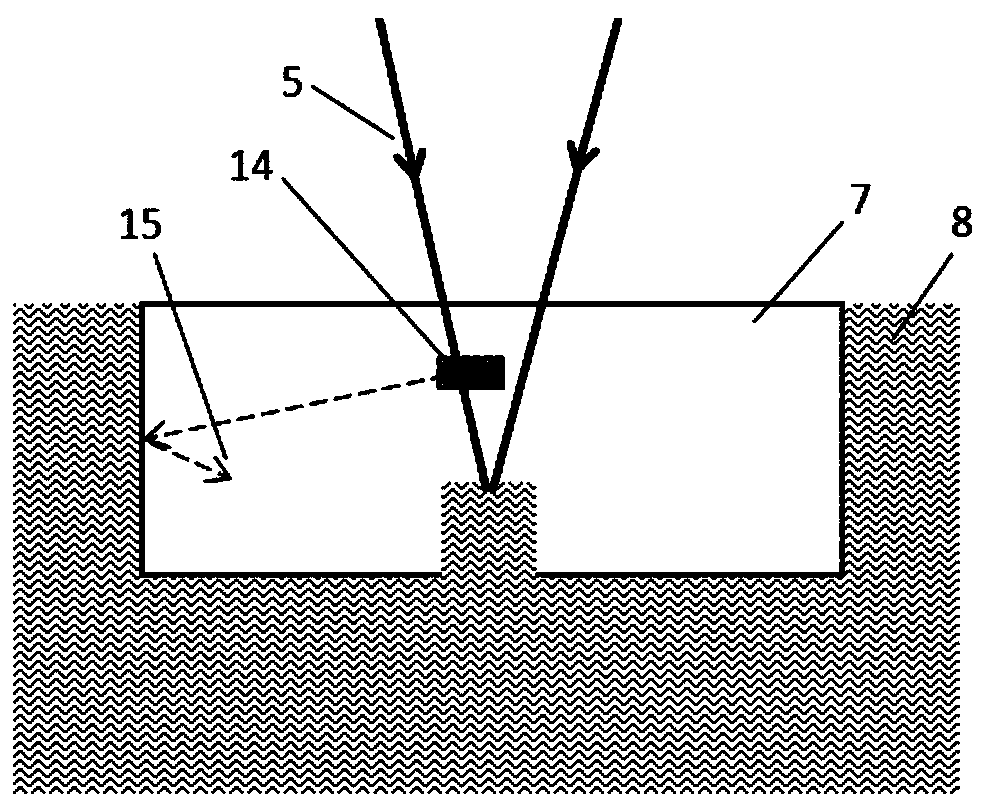

Device and method for auxiliary laser back etching of low-taper glass deep hole by means of liquid flowing coating

ActiveCN110640337AReduce taperReduce crackingLaser beam welding apparatusLaser processingControl system

The invention discloses a device and method for auxiliary laser back etching of a low-taper glass deep hole by means of a liquid flowing coating, and belongs to the field of laser machining in non-traditional machining. The device comprises a laser chemical combined machining system and a control system. The problem that the laser absorption efficiency of transparent hard and brittle material is low is solved. By adopting an alkaline solution added with a colorant, the laser absorptivity of the material machining region can be increased, and the material internal stress accumulation can be reduced. Compared with the prior art that a common solid coating can only achieve the effect at the moment of laser impact, the liquid flowing coating can achieve self-adaptation laser machining of marks, the coating can achieve the continuous effect along with depth changes of laser drilling, and the coating is particularly applicable to machining deep holes. The method sufficiently utilizes the laser pre-machining front face effect, compared with existing methods, the method is low in cost, the deep hole taper can be remarkably lowered, the deep hole wall quality is improved, and the laser energy utilization rate is increased.

Owner:JIANGSU UNIV

Novel technology and equipment for preparing various functional and structural thin films at high speed

InactiveCN104419911APrecise controlStable controlChemical vapor deposition coatingChemical reactionActivation energy

The invention relates to equipment for preparing functional and structural thin films by using a spray-liquid atomizing-multielement eutectoid laser induced chemical vapor deposition method. According to the equipment, a liquid raw material supply system is introduced to replace a solid raw material heating tank which is used by the conventional chemical vapor deposition equipment, so that the problems that the conventional chemical vapor deposition method cannot provide accurate, stable and continuous raw material steam for a long time and the thin film components in the multielement thin film preparation process cannot be accurately controlled and the like can be effectively solved. On the basis, the reaction activation energy among vapor raw material molecules can be reduced to a great extent so as to improve the chemical reaction rate by adopting a method of laser radiation of a surface of a basal plate. Therefore, various oxides and non-oxidized thin films can be accurately, stably and continuously prepared on a large scale at the maximum rate.

Owner:赵培

Czochralski growing method of magnesium aluminate spinel crystal doped with transition metal ions

ActiveCN104005088ASmall sizeQuality improvementPolycrystalline material growthBy pulling from meltIridiumSeed crystal

The invention discloses a growing method of a magnesium aluminate spinel crystal doped with transition metal ions. The molecular formula of the crystal can be expressed as TM2xMgAl2(1-x)O4 and Tm'yMg1-yAl2O4 (TM=Ti<3+>, Cr<3+>, Fe<3+> and Ni<3+>; TM'=Mn<2+>, V<2+> and Co<2+>, 0<x<1, and 0<y<1). The growing method is characterized in that MgAl2O4 polycrystalline raw materials synthesized with the flame method and transition metal oxides prepared according to the proportional concentration are placed in an iridium crucible and sufficiently heated to be molten, the magnesium aluminate spinel crystal or the doped magnesium aluminate spinel crystal is adopted as a seed crystal, and crystal growth is conducted with the Czochralski method. According to the method, the crystal with the large size and high quality can be obtained and be expected to be applied to the fields of micromachining, laser medicine, laser chemistry, laser printing, military application, underwater communication and axis isotope separation.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

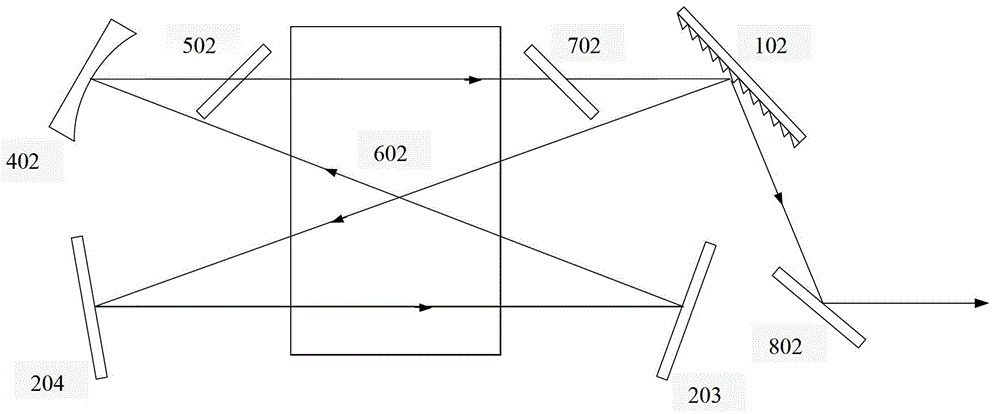

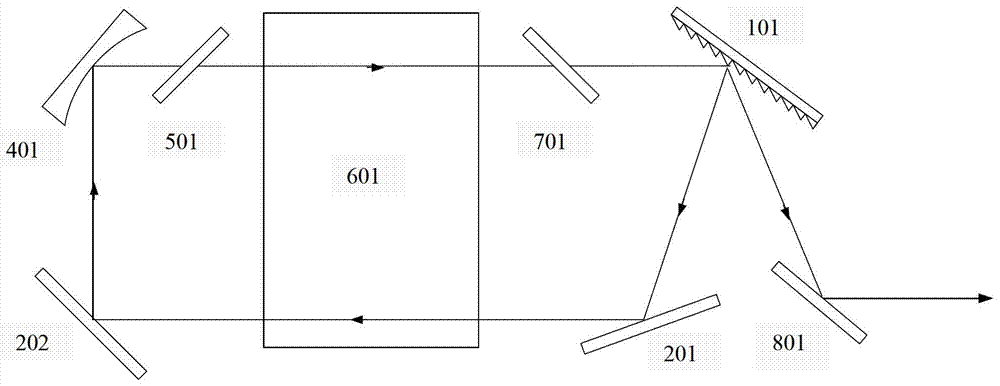

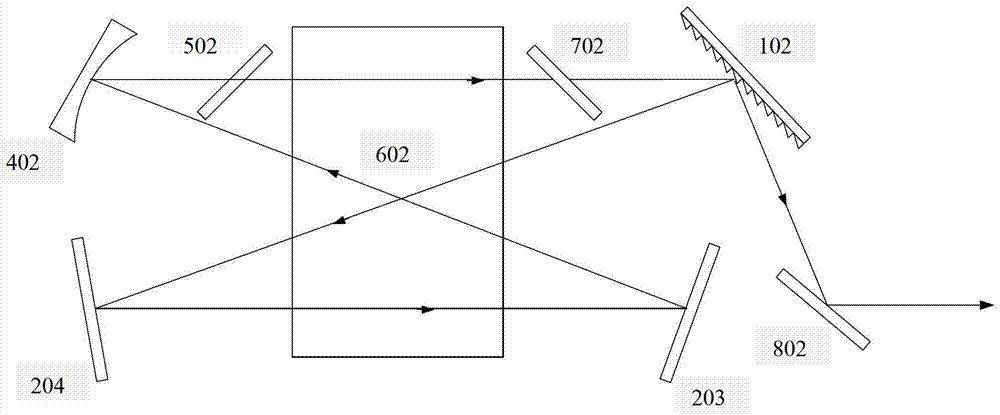

Line selection ring cavity for chemical laser device

The invention relates to a line selection ring cavity for a chemical laser device. The device is in a stable ring cavity structure and is sequentially provided with a blazed grating, a plane mirror, a plane mirror, a plano-concave reflector, a Brewster piece, an activating medium area and a Brewster piece, and a zero level zero level output of the blazed grating is provided with the plane mirrors. According to the laser device provided by the invention, the line selection output of the chemical laser device can be realized by using the zero level, primary diffraction vibration and zero diffraction output. A resonant cavity of the laser device is in either a four-mirror rectangular travelling-wave cavity or a four-mirror '8'-shaped annular travelling-wave cavity, therefore, the laser device can more effectively extract active particles in a gain medium area and the output power of the line selection laser can be improved; furthermore, the line selection ring cavity has the characteristics of compact structure, high power, good beam quality, high stability and the like, thereby being extensively applied to the fields of laser physics, laser chemistry, materials processing and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

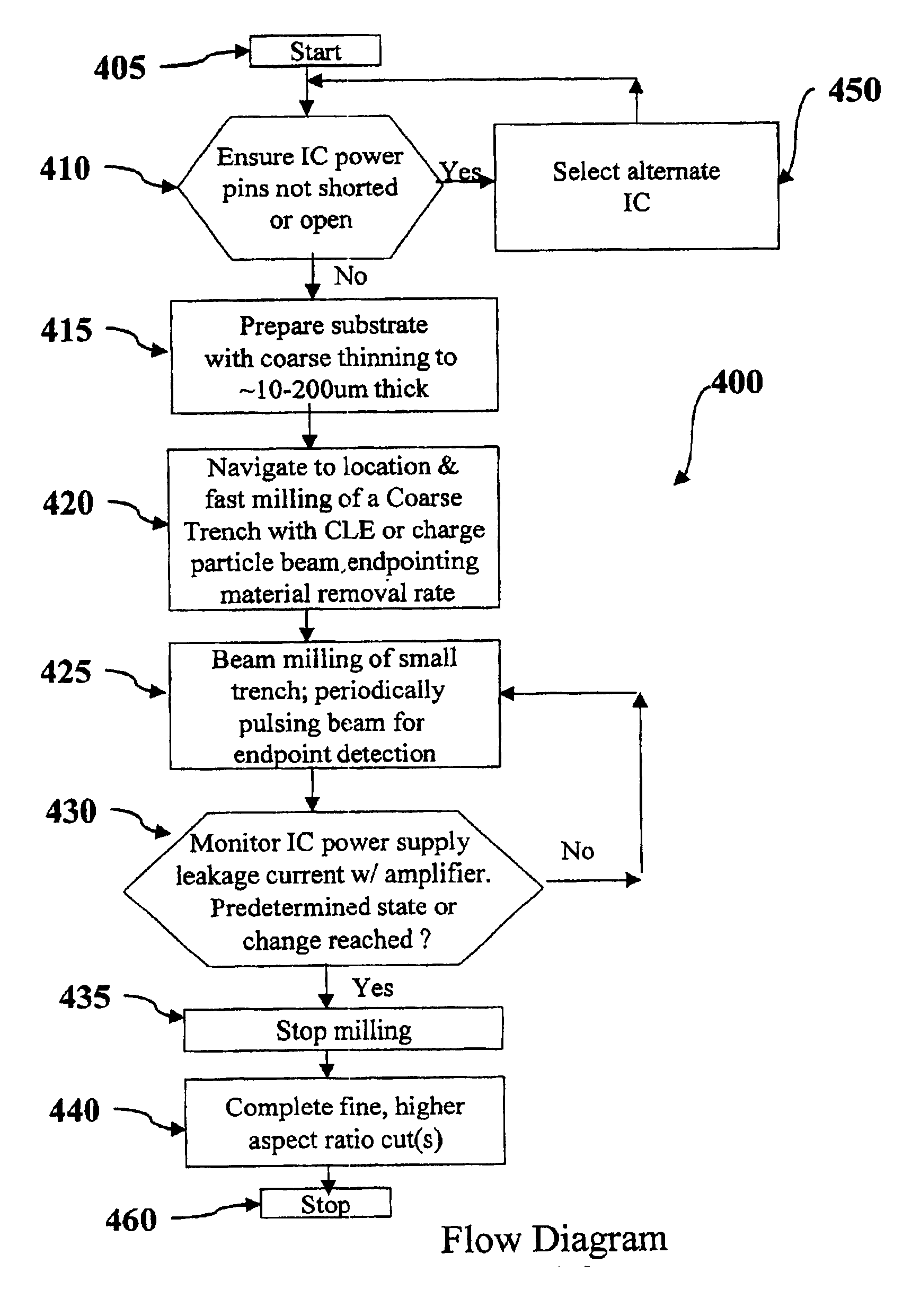

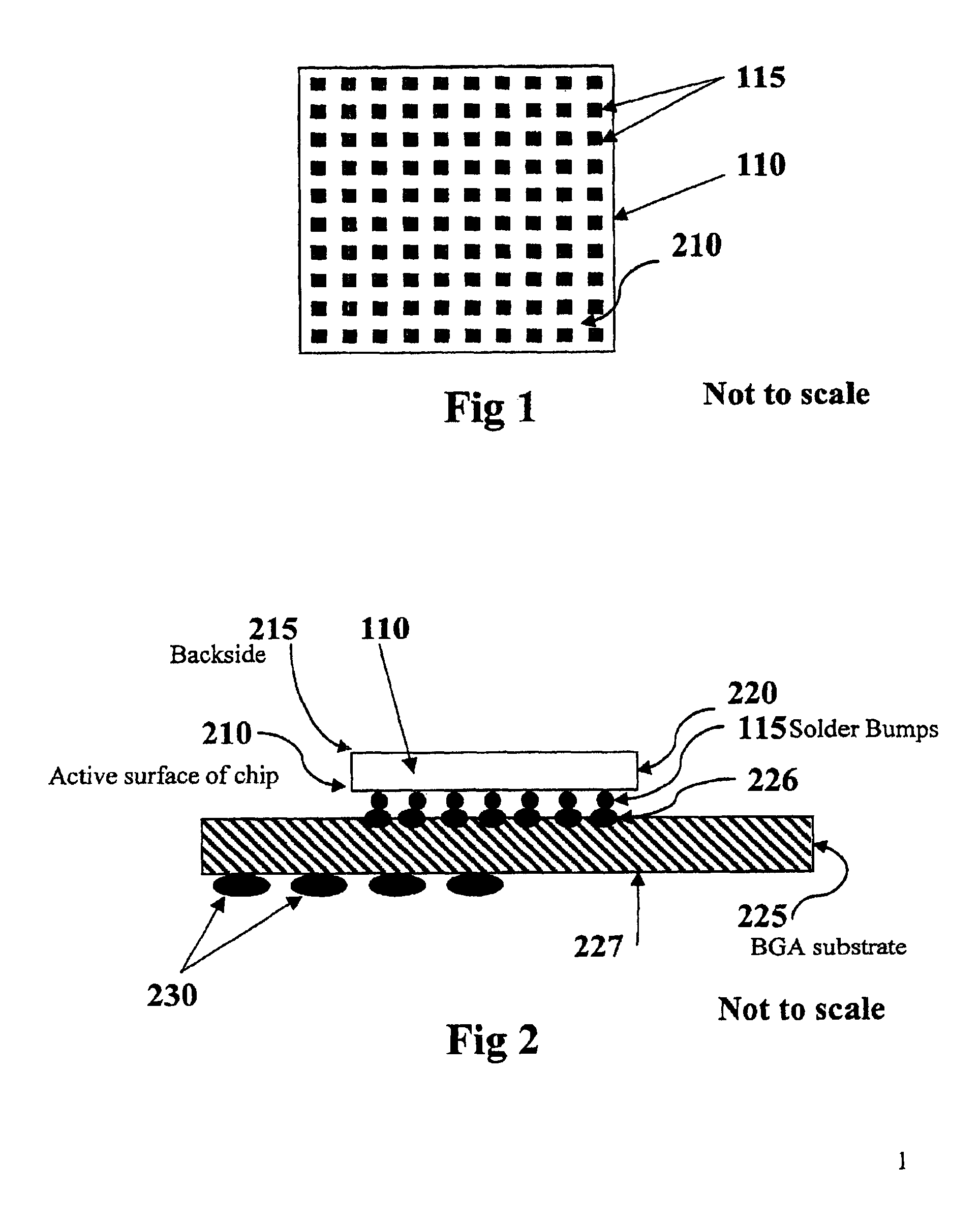

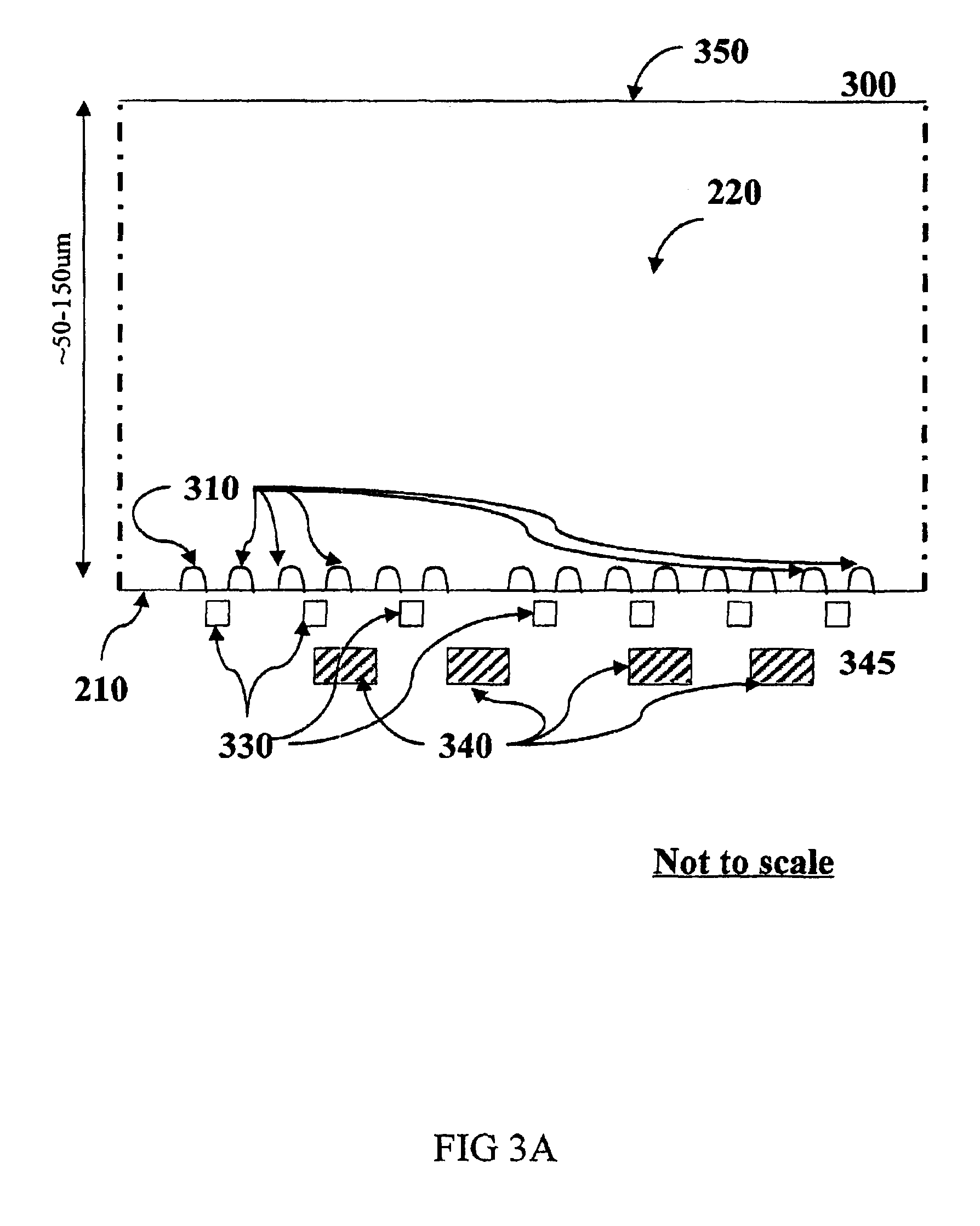

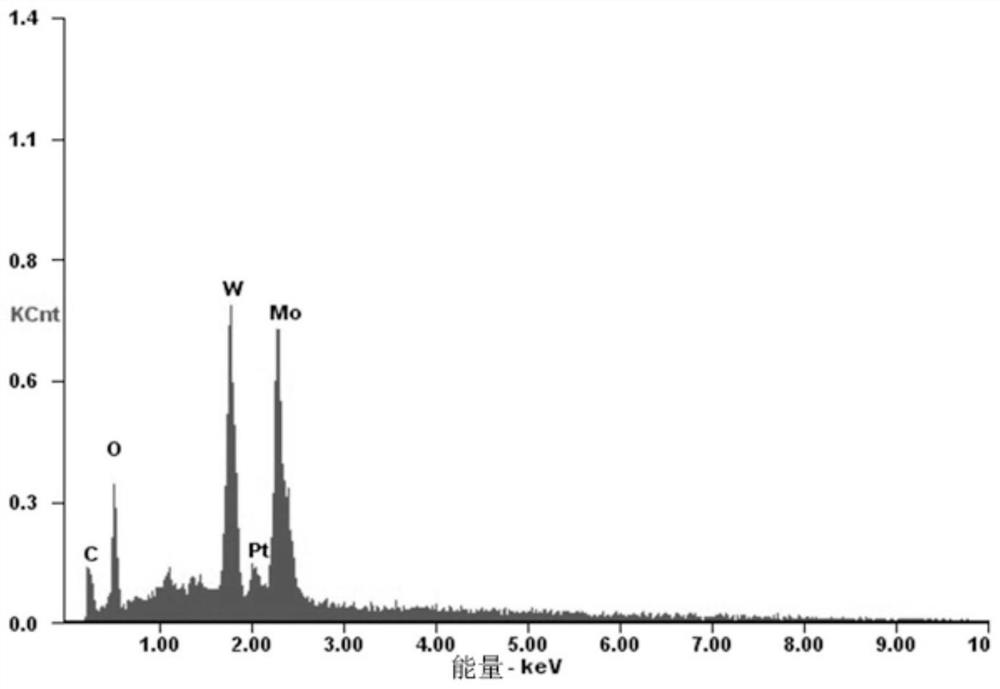

Precise, in-situ endpoint detection for charged particle beam processing

InactiveUS6905623B2Low costLess complexElectric discharge tubesVacuum gauge using ionisation effectsElectron holeEtching

A system and method for determining precisely in-situ the endpoint of halogen-assisted charged particle beam milling of a hole or trench in the backside of the substrate of a flipchip packaged IC. The backside of the IC is mechanically thinned. Optionally, a coarse trench is then milled in the thinned backside of the IC using either laser chemical etching or halogen-assisted charged particle beam milling. A further small trench is milled using a halogen-assisted charged-particle beam (electron or ion beam). The endpoint for milling this small trench is determined precisely by monitoring the power supply leakage current of the IC induced by electron-hole pairs created by the milling process. A precise in-situ endpoint detection signal is generated by modulating the beam at a reference frequency and then amplifying that frequency component in the power supply leakage current with an amplifier, narrow-band amplifier or lock-in amplifier. The precise, in-situ, endpoint signal is processed and displayed for manual or automatic precise in-situ endpoint detection. This approach avoids or minimizes unintentional damage or perturbation of the active diffusion regions in the IC. A range of further operations on the IC can then be performed.

Owner:CREDENCE SYSTEMS

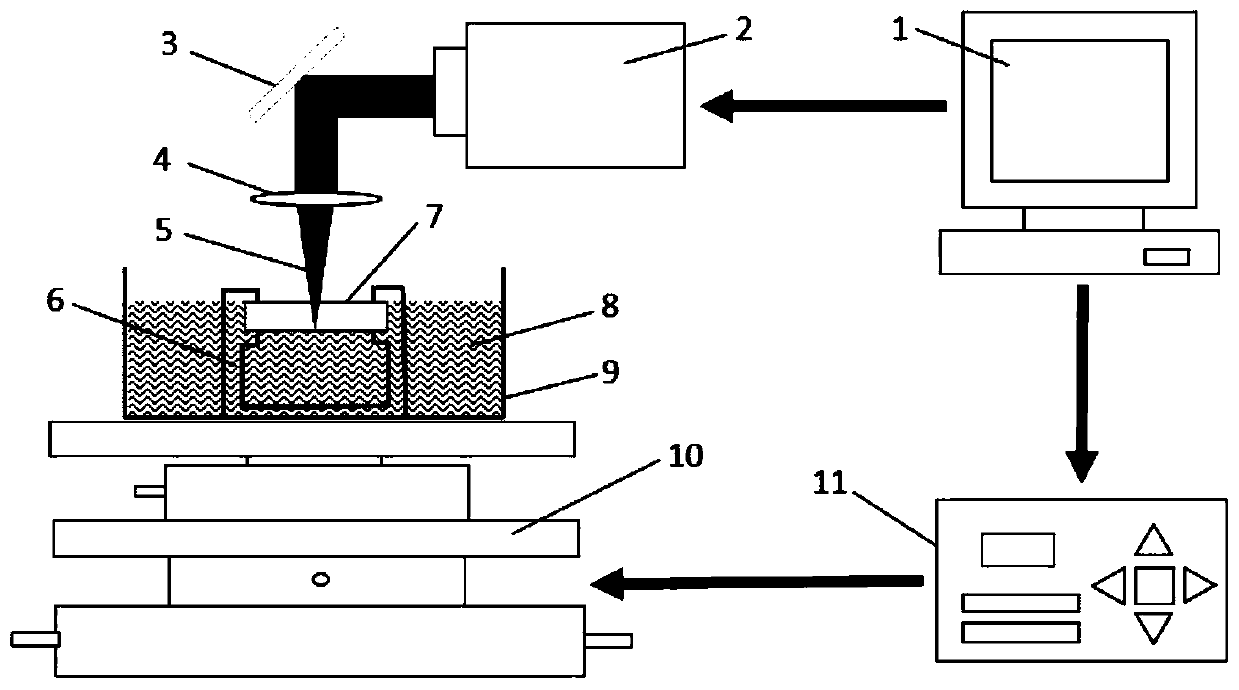

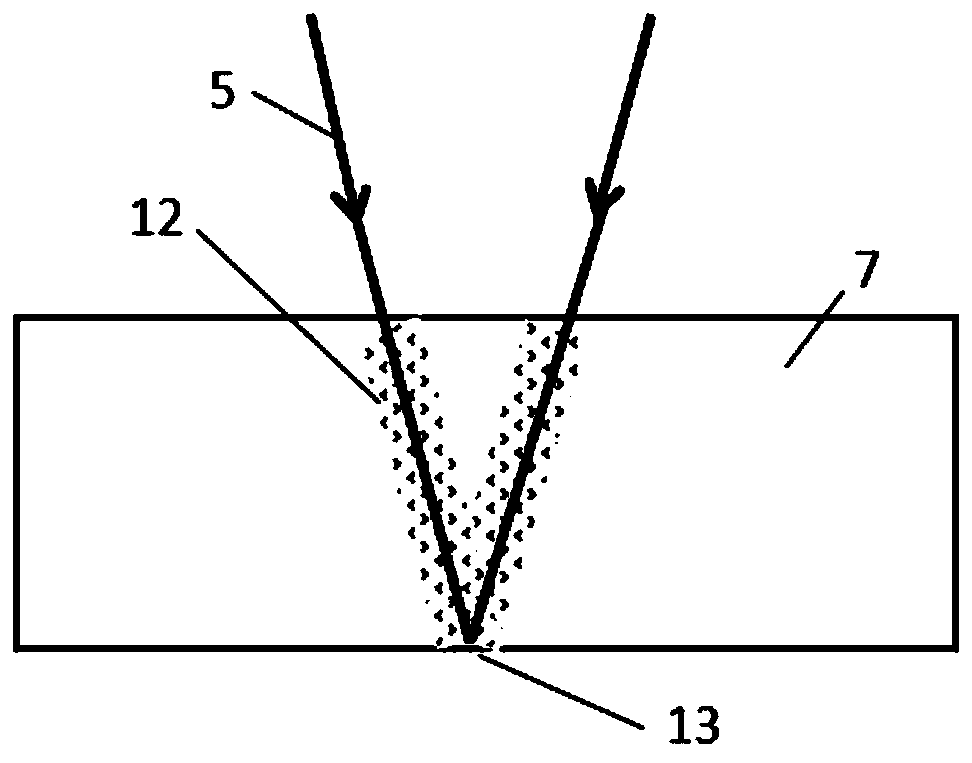

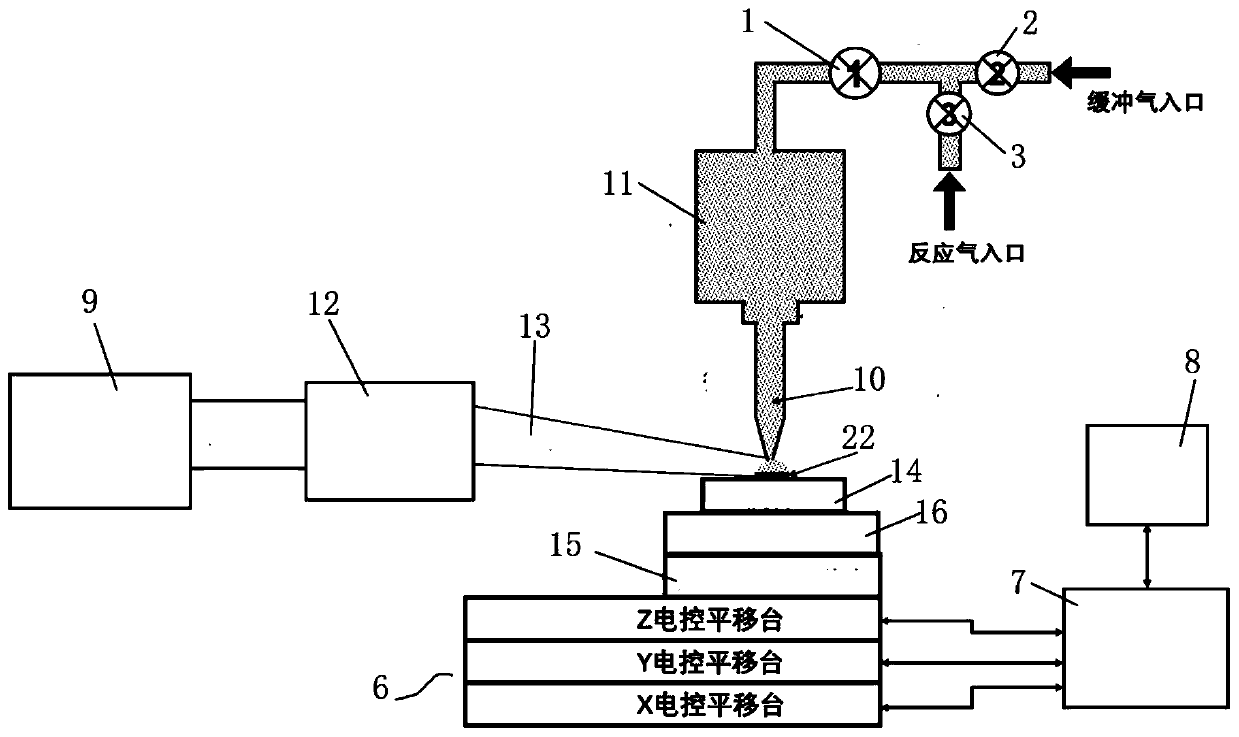

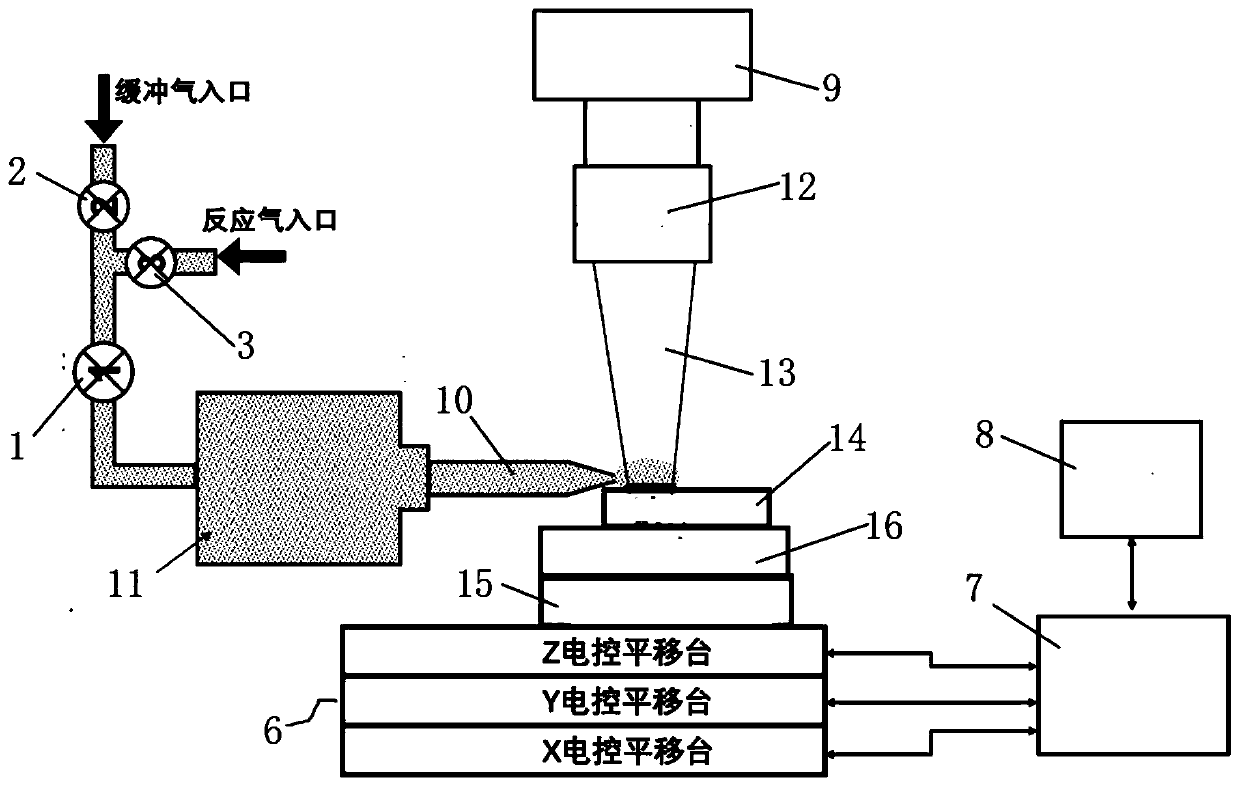

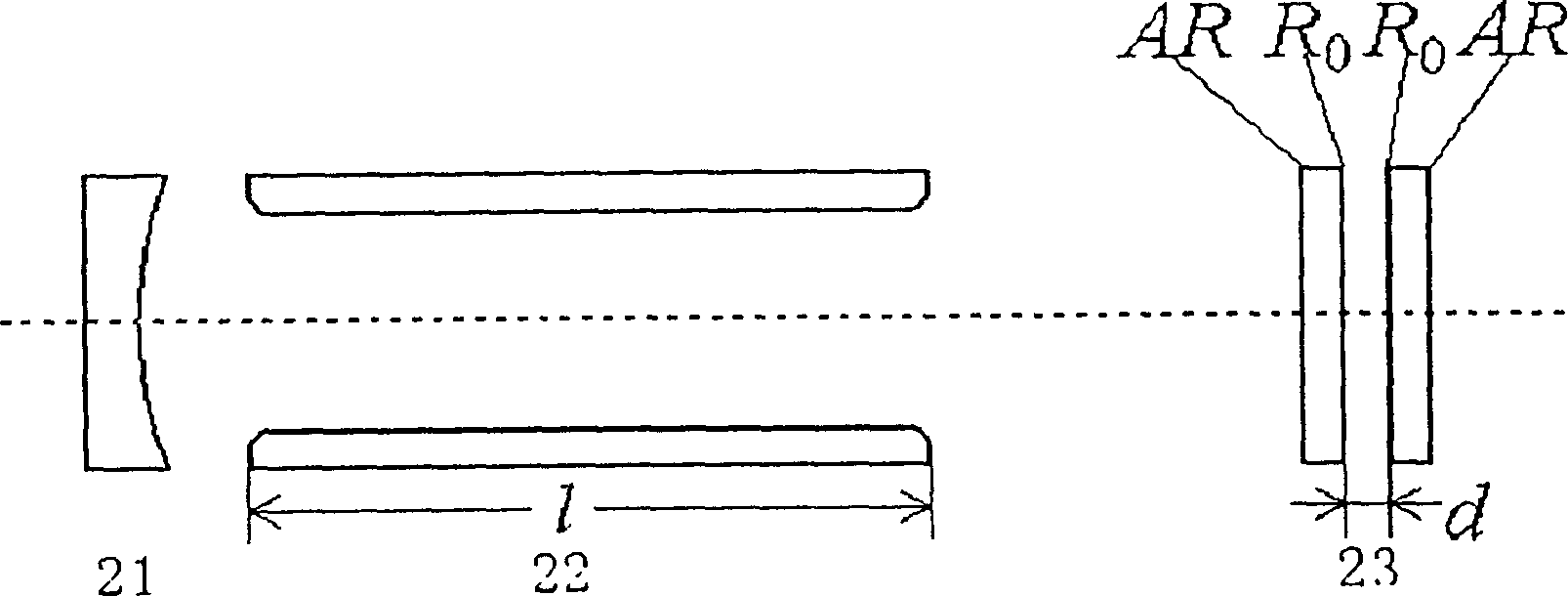

Micro-nano three-dimensional printing method and device based on laser chemical vapor deposition

ActiveCN110512193ADiffusion is weakImprove printing accuracyAdditive manufacturing apparatusChemical vapor deposition coatingMicron scaleMicro nano

The invention provides a micro-nano three-dimensional printing method based on laser chemical vapor deposition; and the laser chemical deposition is combined with a localized gas injection technologybased on a micropipe to realize micro-nano 3D printing of wide material systems and to improve the printing precision. Laser beams emitted by a laser are collected to microareas to be processed on thesurfaces of samples after passing through an optical element set; reaction gas and buffer gas are mixed and injected in a gas cavity; the gas cavity communicates with the micropipe by an adapter; themixed gas of the reaction gas and the buffer gas is injected to the microareas to be processed on the surfaces of the samples by the tip end of the micropipe, and is radiated by the collected laser beams; under the laser pyrolysis effect and / or the photolysis effect, the reaction gas is dissociated, and the decomposed products are deposited on the surfaces of the products to form plating layers;the inner diameter of the tip end of the micropipe is nanometer or micron-scale; and according to preset patterns, an electric control translation platform is adjusted to move in a coordinated mode torealize three-dimensional relative movement of the micropipe and the surfaces of the samples so as to generate three-dimensional micro-nano patterns.

Owner:橙河微系统科技(上海)有限公司

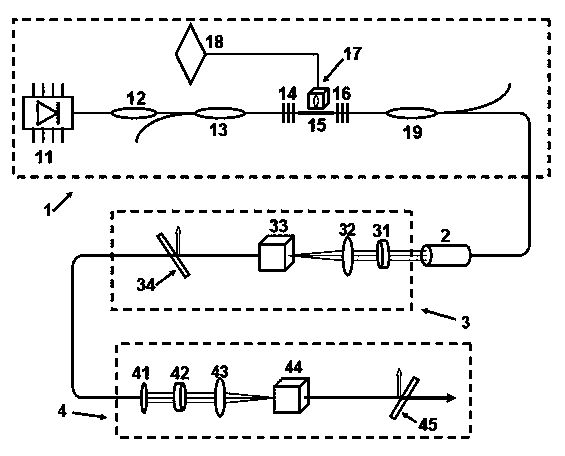

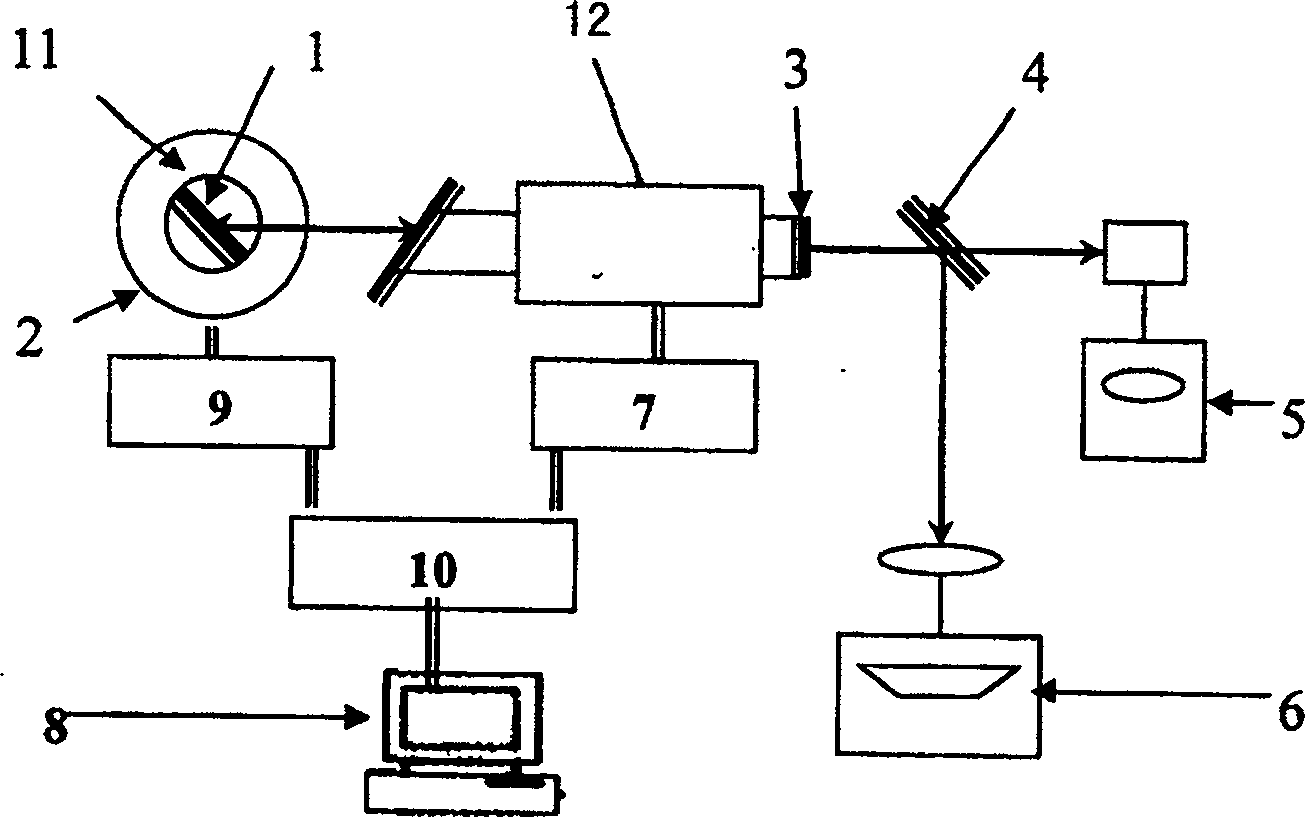

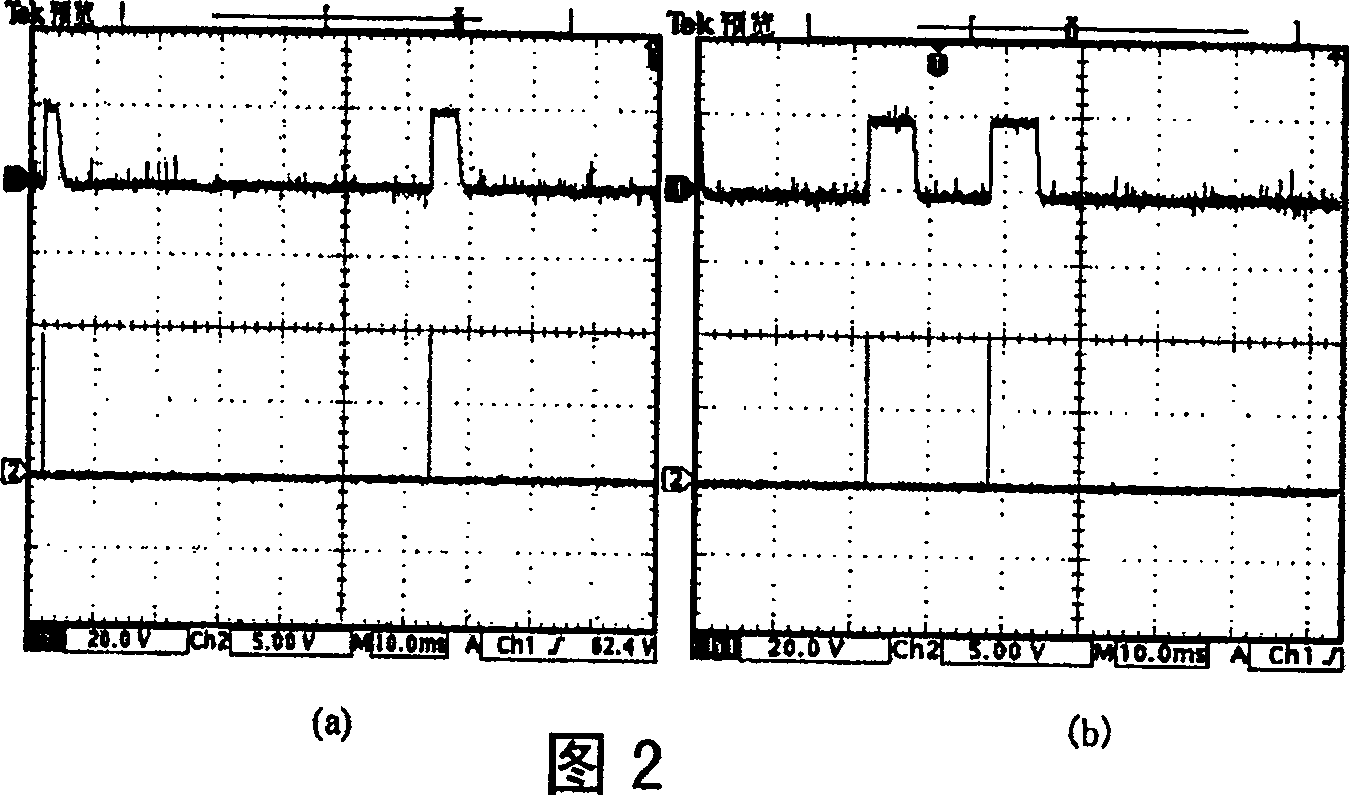

Novel single-frequency pulse ultraviolet light source on basis of 978nm single-frequency pulse optical fiber laser

The invention discloses a novel single-frequency pulse ultraviolet light source on the basis of 978nm single-frequency pulse optical fiber laser, which is characterized by comprising a linear polarization single-frequency Q-switched pulse 978nm all-optical-fiber laser 1, a collimator 2, a first frequency doubling system 3 and a second frequency doubling system 4, wherein 978nm single-frequency pulse optical fiber laser is collimated and output at the signal end of the linear polarization single-frequency Q-switched pulse 978nm all-optical-fiber laser 1 by the collimator 2 and then single-frequency pulse ultraviolet light is output by the first frequency doubling system 3 and the second frequency doubling system 4. According to the invention, on the basis of the single-frequency pulse all-optical-fiber laser, the 978nm single-frequency pulse light output by the single-frequency pulse all-optical-fiber laser is subjected to frequency doubling for twice and generation of the single-frequency pulse ultraviolet light is implemented; and the novel single-frequency pulse ultraviolet light source has important application value in the fields of molecules, atom detection, laser spectroscopy, laser chemistry and biomedicine.

Owner:HFB PHOTONICS CO LTD

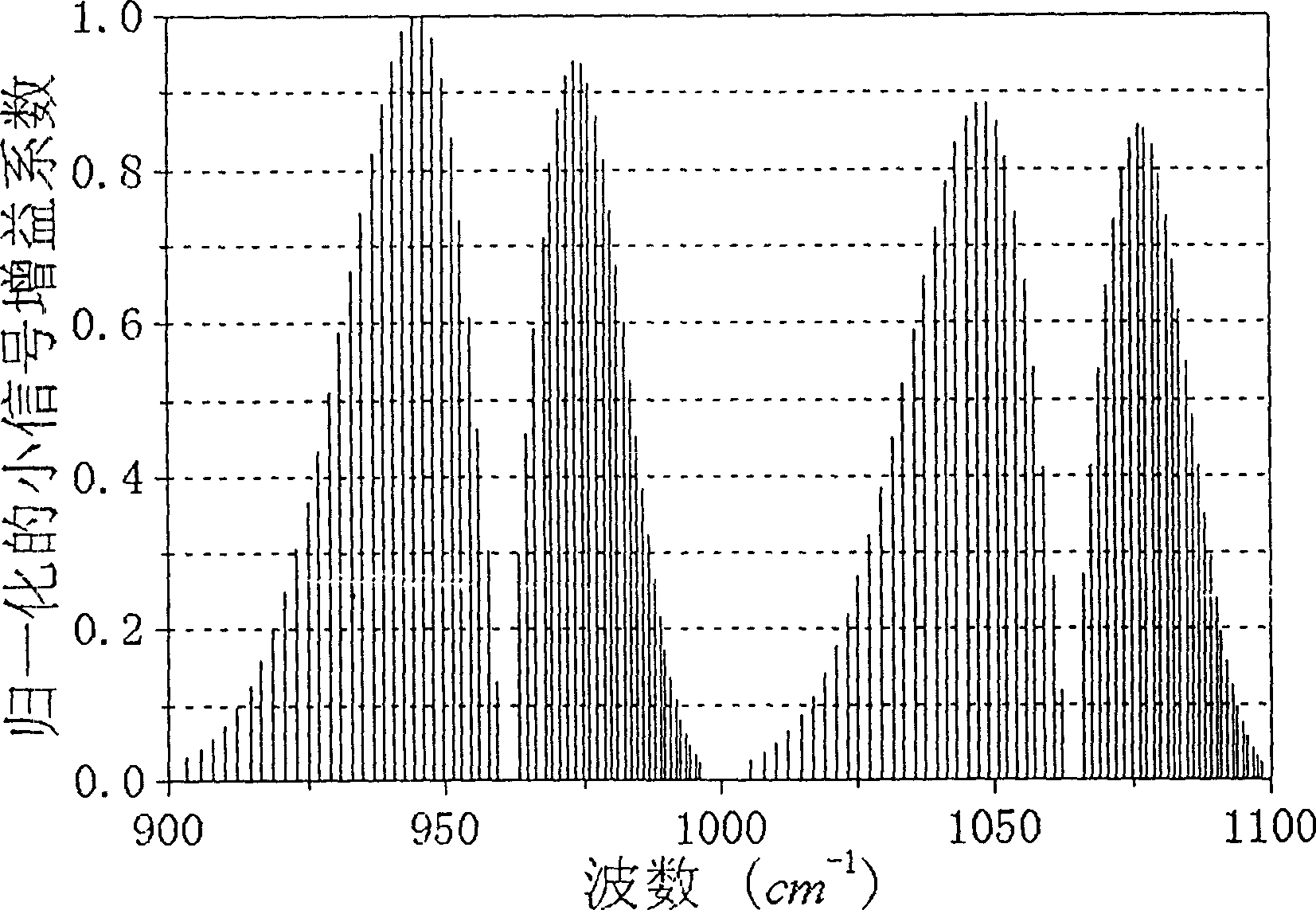

Two-stage injection amplification apparatus based on large-power airflow chemical laser system

ActiveCN104064958AGet Line Select OutputOutput is easy to implementLaser arrangementsAudio power amplifierOptoelectronics

The invention relates to a two-stage injection amplification apparatus based on a large-power airflow chemical laser system. The apparatus comprises a seed laser, a primary injection amplifier and a secondary injection amplifier. The apparatus employs such a structure that seed laser is injected to a primary laser amplifier for amplification first and then is injected to the secondary amplifier for amplification output. The seed laser is a single-mode line-selection chemical laser, the primary injection amplifier employs an "8-shaped" annular cavity structure, and the secondary injection amplifier employs a rectangular cavity structure so as to realize amplification output of line-selection airflow chemical laser. According to the invention, the apparatus can realize high-power, single-mode and line polarization output of the line-selection chemical laser, thereby being widely applied to such fields as laser physics, laser chemistry and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

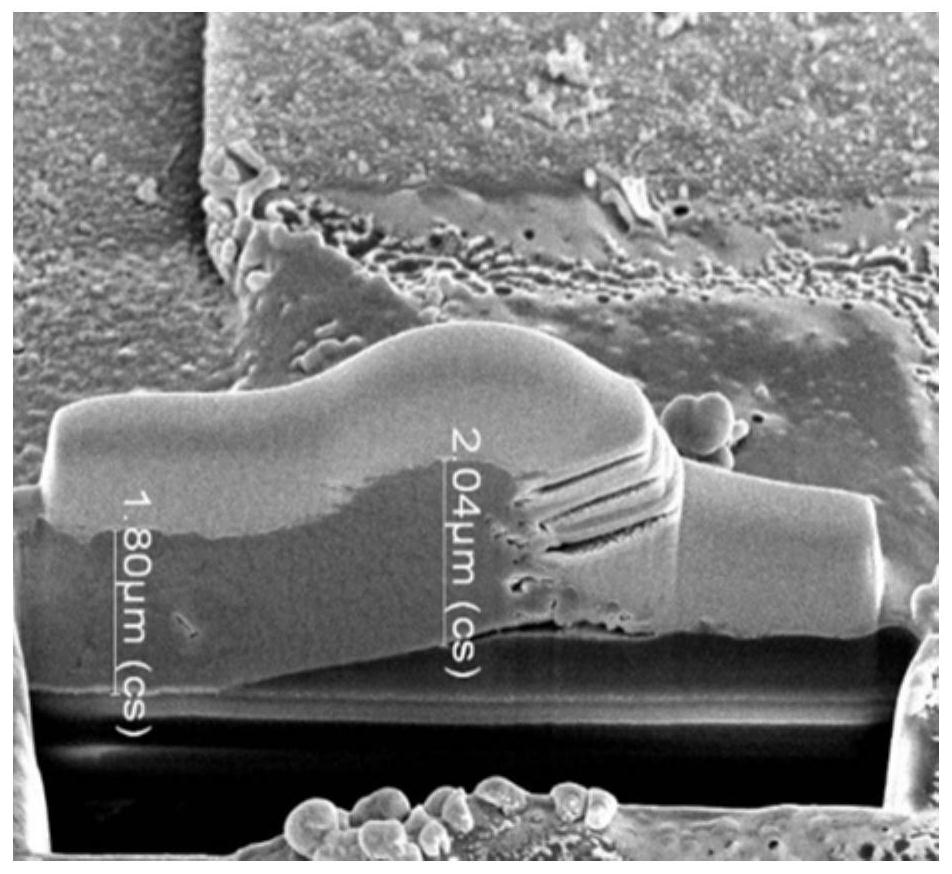

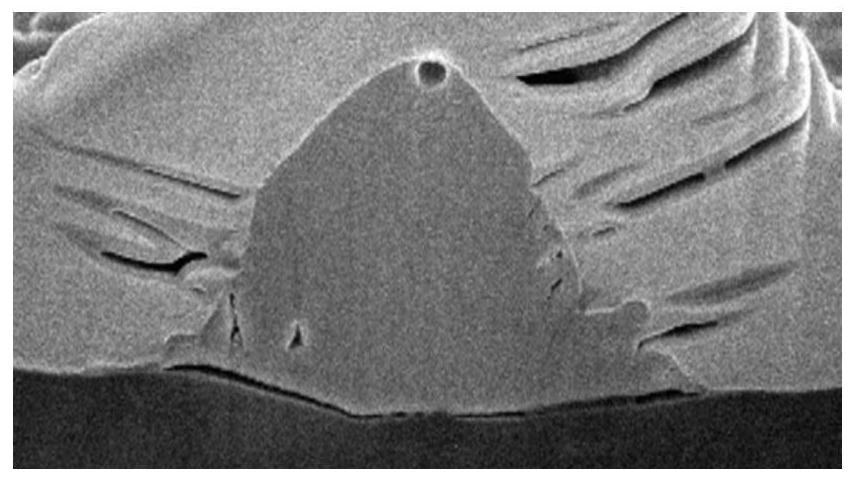

Method for forming micro wire by using laser chemical vapor deposition

PendingCN111615868AAvoid short circuitSemiconductor/solid-state device manufacturingPrinted circuit secondary treatmentPhysical chemistryAlloy deposition

Disclosed is a micro wire forming method comprising the steps of: forming an alloy wire comprising multiple metal elements on a substrate while supplying a source gas comprising multiple metal elements through laser chemical vapor deposition (LCVD); and performing laser heat treatment in an area comprising the metal wire. According to the micro wire forming method of the present invention, a microwire is formed primarily in an LCVD type, a high-thickness growth having a narrow width and an excellent film quality is accomplished within a short period of time through alloy deposition, and innerfilm quality defects of the micro wire are removed through subsequent laser heat treatment. Accordingly, the texture compactness and the film quality can be improved, and the uniformity and the conductive stability can be increased. In addition, the emission width, the output intensity, and the emission type are adjusted such that patterns are condensed in the process of partial melting and cooling, thereby forming a micro wire having a line width of 2 [mu]m or less.

Owner:苏州科韵激光科技有限公司

Device and method for preventing crystallization of deposition gas in laser chemical vapor deposition

PendingCN112680723APrevent crystallizationAvoid cloggingChemical vapor deposition coatingTwo temperatureEngineering

The invention relates to a device and a method for preventing crystallization of deposition gas in laser chemical vapor deposition. The device comprises a deposition gas storage container, a reaction cavity and a pipeline connecting the deposition gas storage container and the reaction cavity and used for conveying the deposition gas, and the pipeline comprises at least two temperature loss areas in the flow direction of the deposition gas. Corresponding to the temperature loss areas, the device is further provided with a temperature maintaining device and a first temperature monitoring device, and the monitoring target temperature of the first temperature monitoring device is in an increasing trend. By means of the device, the deposition gas in the pipeline can be kept in a continuous gasification state, the phenomenon that the deposition gas is solidified and crystallized when meeting cold in the pipeline or on a base plate in the reaction cavity is effectively prevented, the serious problems that the pipeline is blocked or the base plate is scrapped are effectively avoided, and huge economic losses are effectively avoided.

Owner:苏州科韵激光科技有限公司

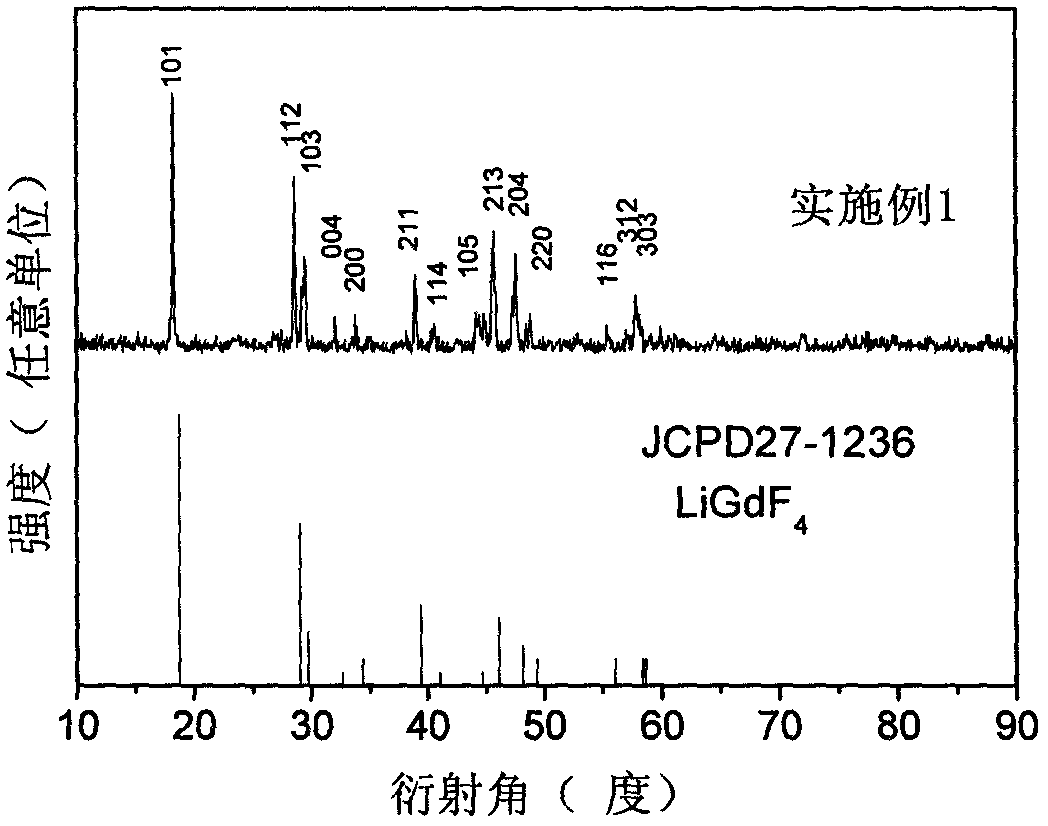

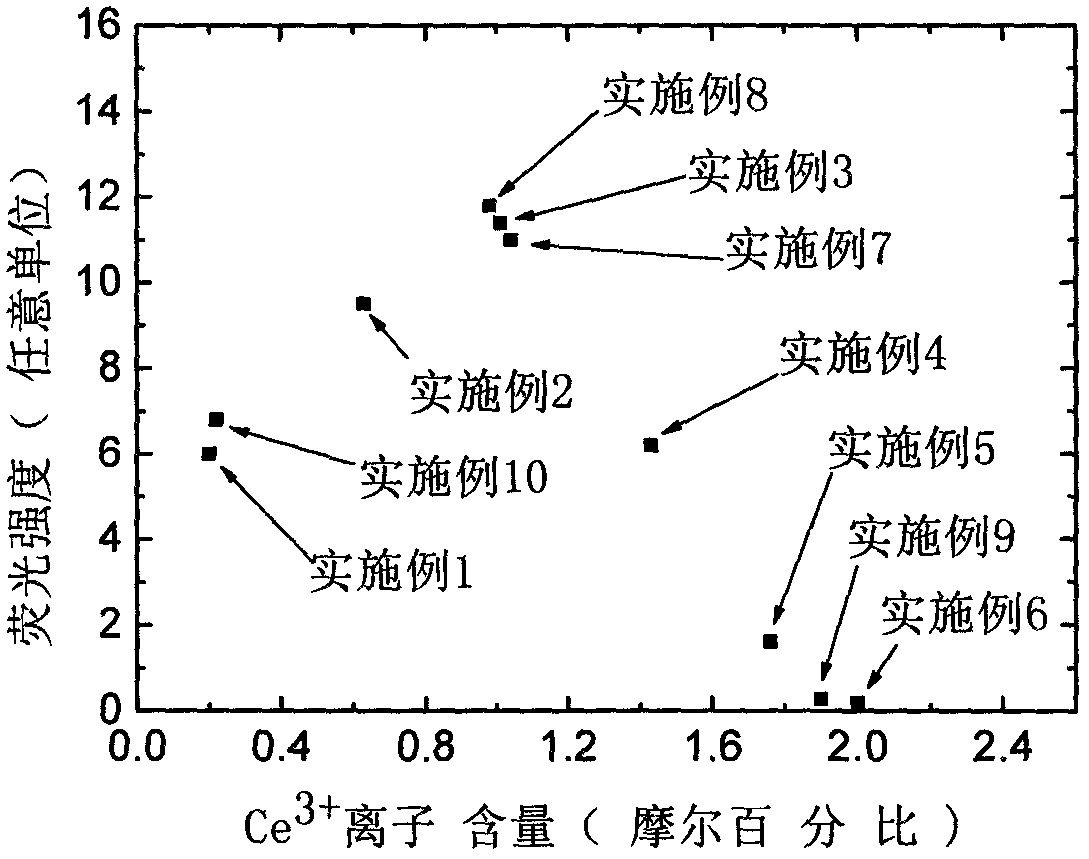

Ce<3+> doped gadolinium lithium fluoride ultraviolet laser crystal and preparation method thereof

InactiveCN103820854AQuality improvementReduce volatilityPolycrystalline material growthFrom frozen solutionsSpectroscopyMaterials processing

The invention discloses a Ce<3+> doped gadolinium lithium fluoride ultraviolet laser crystal and a preparation method thereof. Ce<3+> rare earth ions are doped into LiGdF4 crystals to generate monocrystals with the chemical formula of LiGd(1-alpha)CealphaF4. The fluoride monocrystals have the characteristics of low growth temperature, uniform distribution of Ce<3+>, small stress, and good calorimetric, mechanical and chemical stability. The preparation method adopts a water and oxygen insulation sealed crucible descent technology and allows raw materials to undergo high temperature fluorination treatment in order to obtain high-quality crystals containing almost no hydroxide ions. The crystals emit strong 300-345nm ultraviolet fluorescence under the excitation of light with the wavelength of 296nm, and can be expected to be applied in the laser medicine field, the material processing field, the laser spectroscopy field, the laser chemistry field and the like.

Owner:NINGBO UNIV

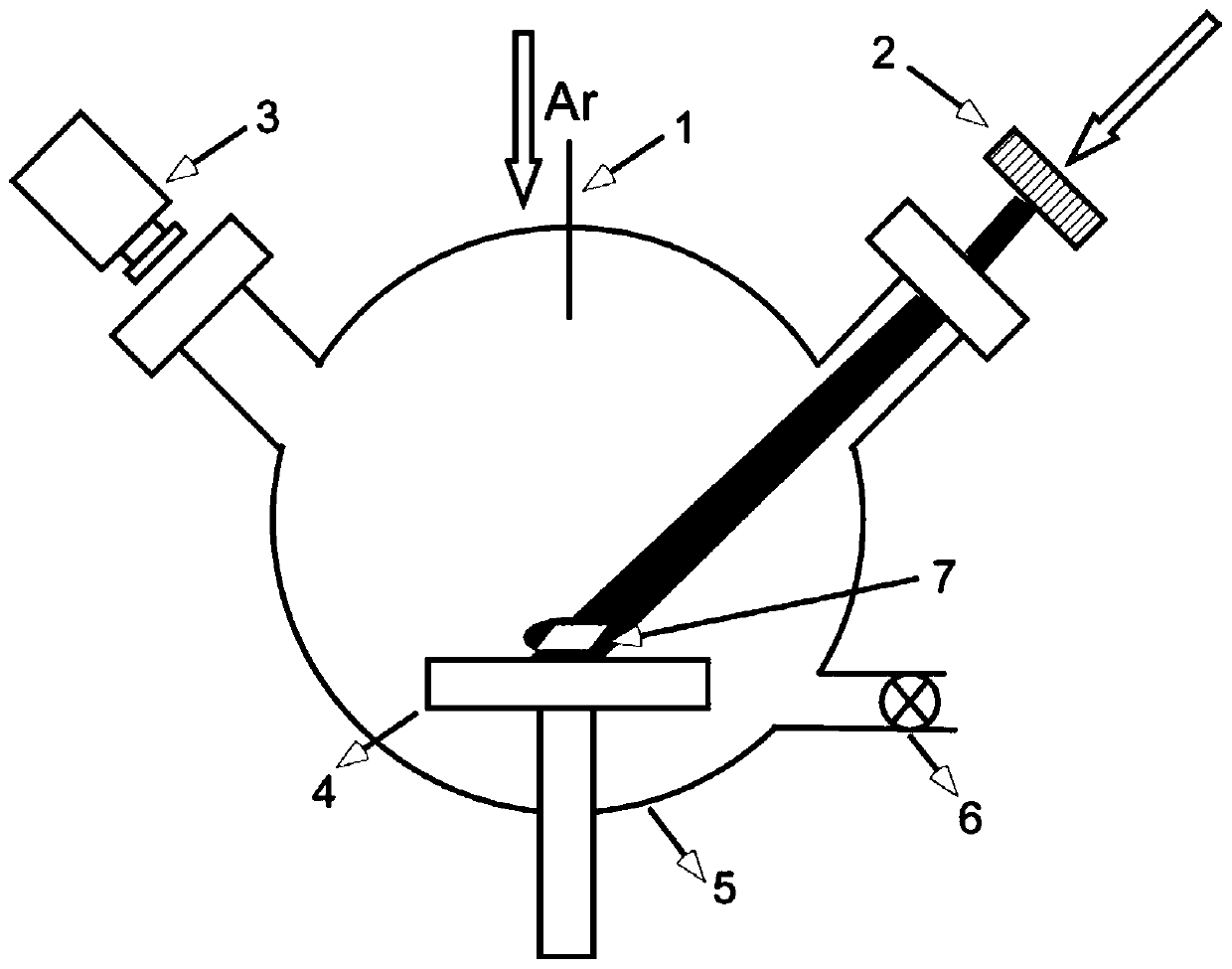

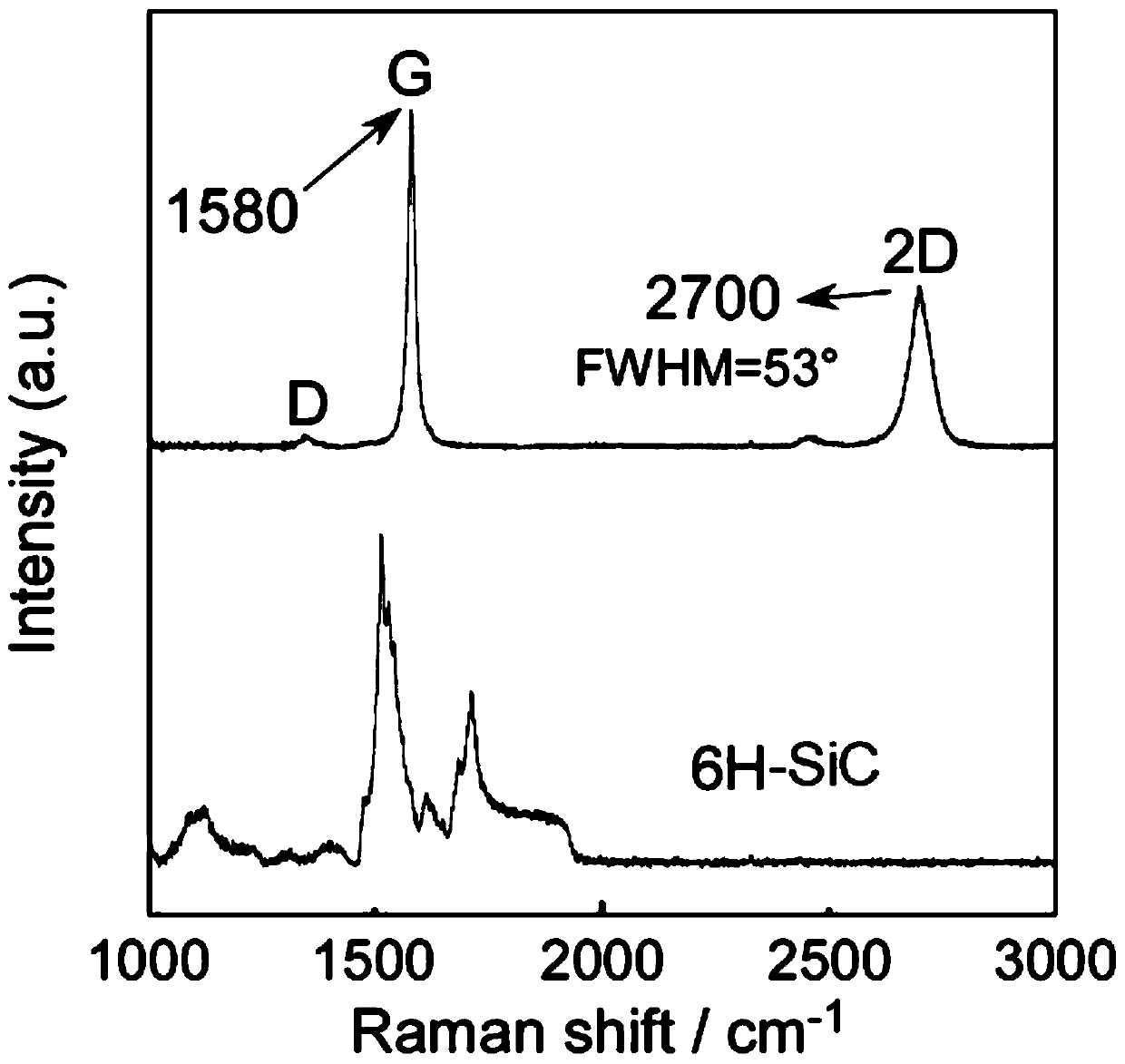

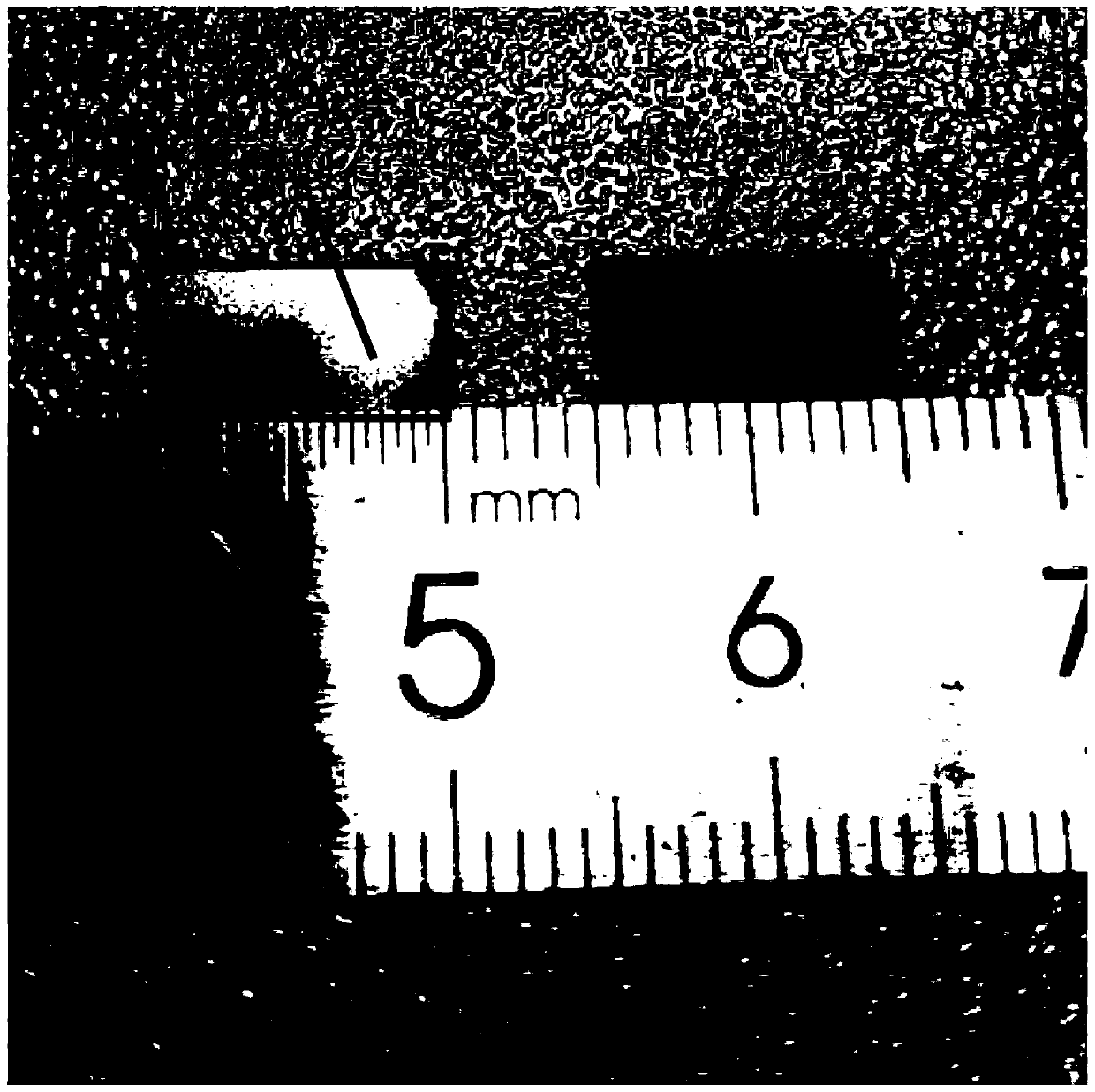

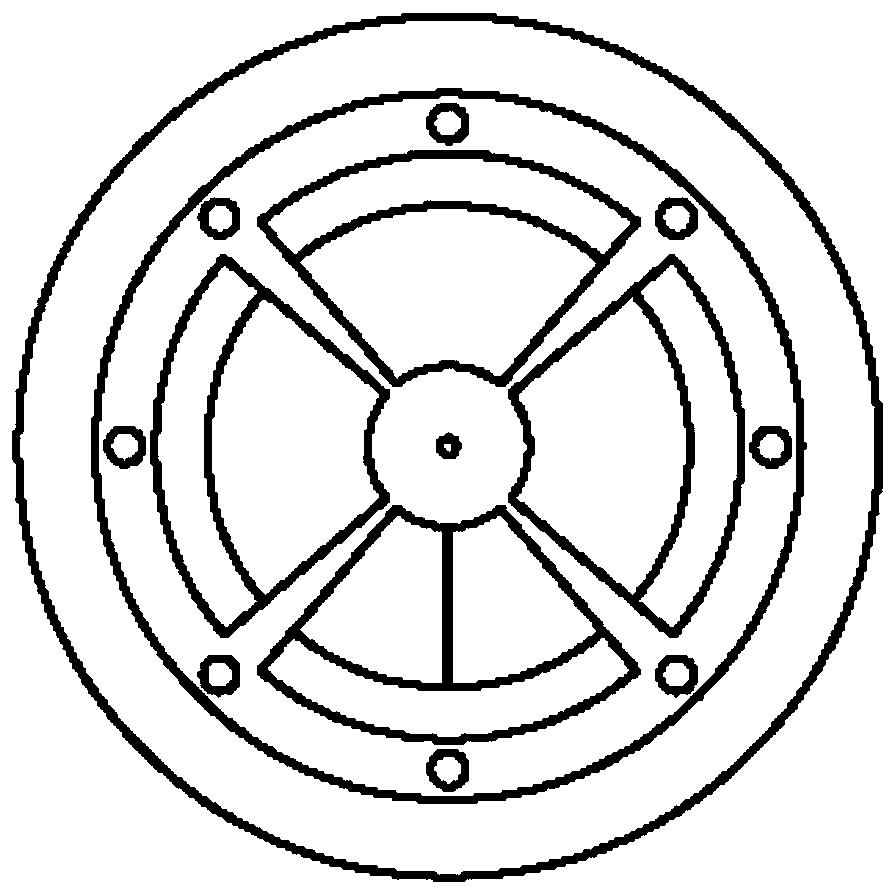

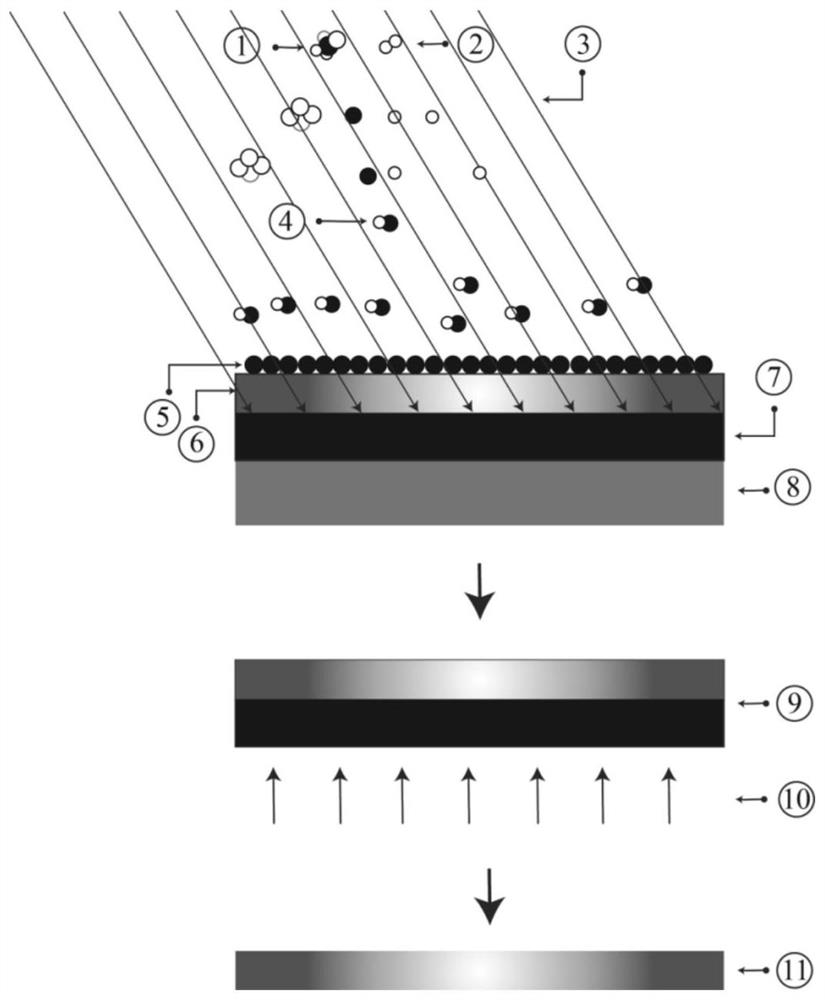

Method for preparing epitaxial graphene through laser heating

ActiveCN111017914AReduce square resistanceThe number of layers is controllableGraphenePhysical chemistryGraphite

The invention provides a method for preparing epitaxial graphene by laser heating. The method comprises the following steps: 1) putting a SiC substrate into a deposition cavity of a laser chemical vapor deposition device, and introducing high-purity Ar gas into the cavity to regulate the gas pressure in the cavity to 1000-10000 Pa; (2) starting laser to irradiate the SiC substrate to heat the surface of the substrate to 1500-2000 DEG C at a rate of 400-600 DEG C / s, and continuously irradiating for 1-5 min; and 3) adjusting the laser power to reduce the temperature of the surface of the substrate to 600 DEG C at a rate of 100-200 DEG C / s, and naturally cooling to room temperature to obtain the epitaxial graphene on the surface of the SiC substrate. The method can rapidly prepare the epitaxial graphene with a large growth area, and the prepared epitaxial graphene has the characteristics of high conductivity, controllable layer number and high crystal quality.

Owner:气相科技(武汉)有限公司

Laser chemistry-microwave ceramic preparation method

InactiveCN108484170ALarge specific surface areaHigh specific surface energyCeramicwareLaser beam welding apparatusMicrowaveHigh activity

The invention discloses a laser chemistry-microwave ceramic preparation method. According to the laser chemistry-microwave ceramic preparation method, the depth of conduction of heat generated by interaction between laser and ceramic into a substrate is reduced, so that the thickness of a recast layer produced due to heat melting and rapid cooling is reduced; a laser beam irradiates a ceramic sample, and the energy density at a focus of the laser beam exceeds a ceramic failure threshold, so that the ceramic at a cutting position is vaporized into ceramic particles; the vaporized ceramic particles are quickly removed by blowing in compressed air so as to avoid affecting subsequent machining. The ceramic prepared by the laser chemistry-microwave ceramic preparation method provided by the invention has the advantages of high specific surface area, high specific surface energy, high activity and easy sintering, so that the ceramic is easily cut; in addition, an adsorbent is used for adsorbing laser energy, so that the cutting efficiency is improved.

Owner:李冰雪

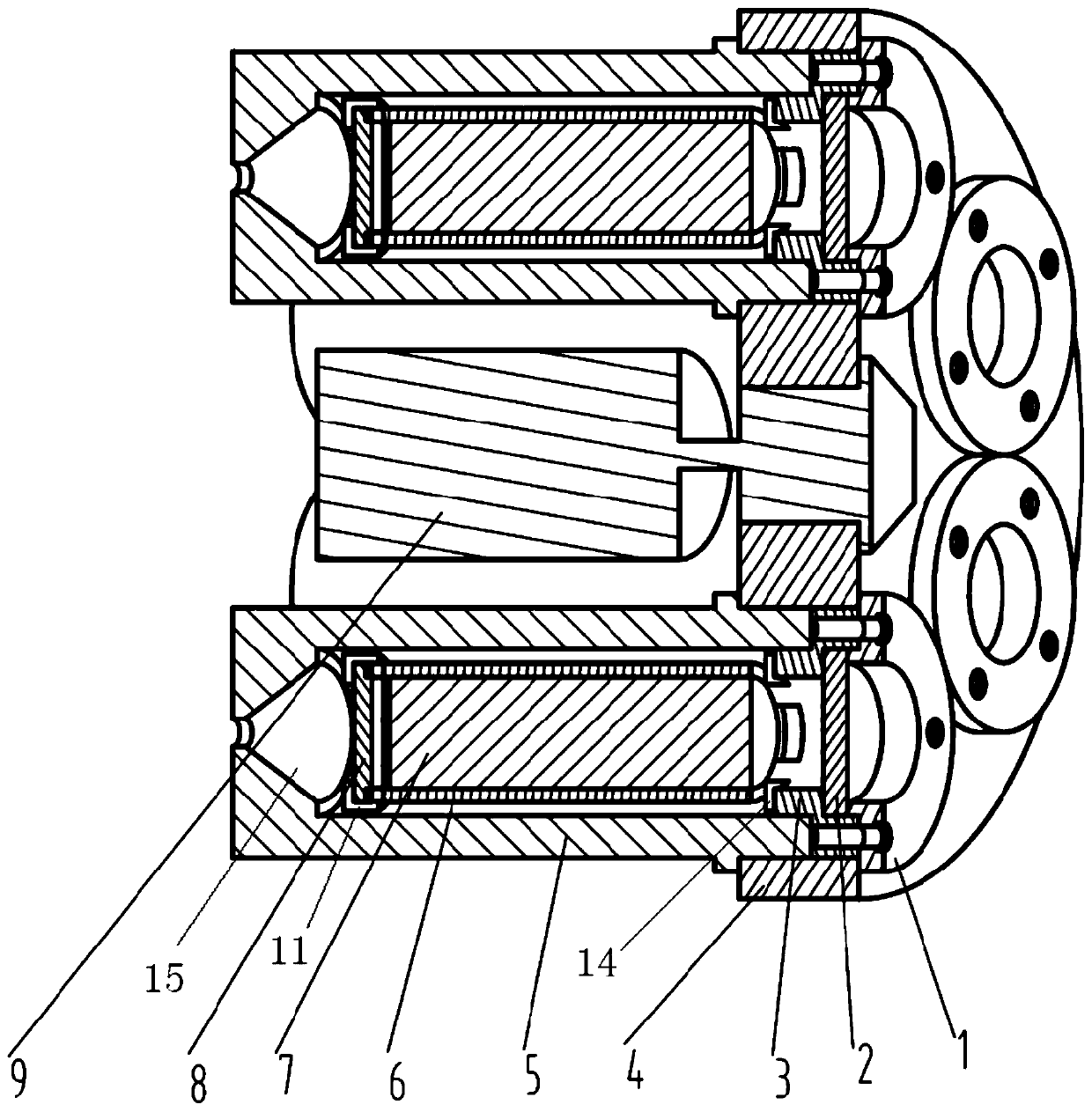

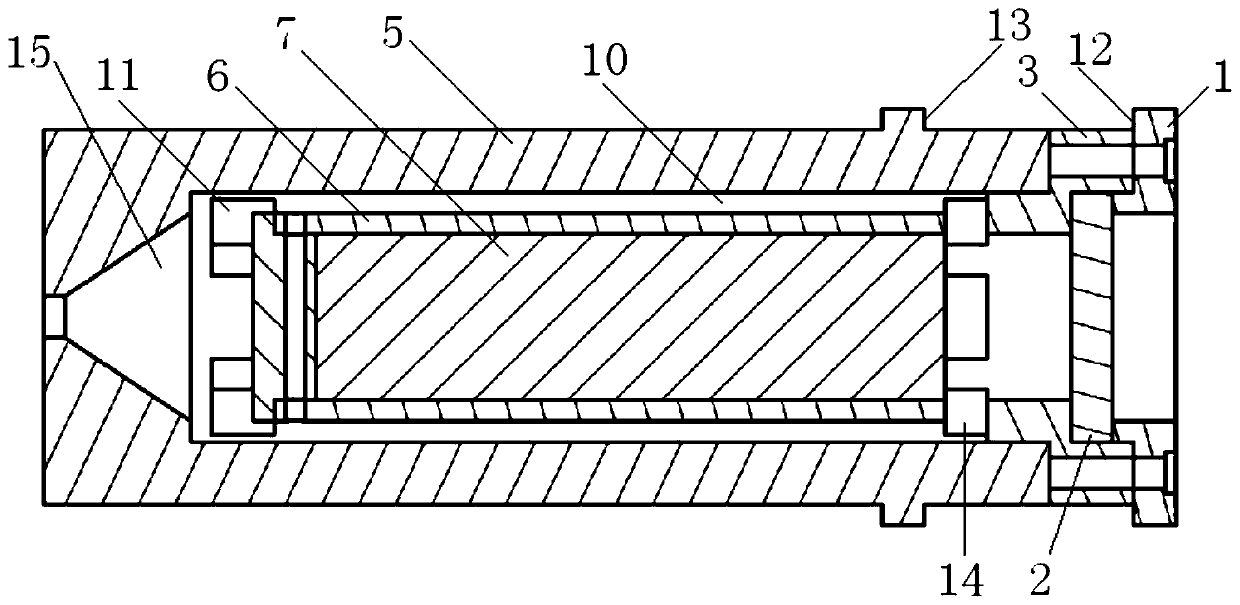

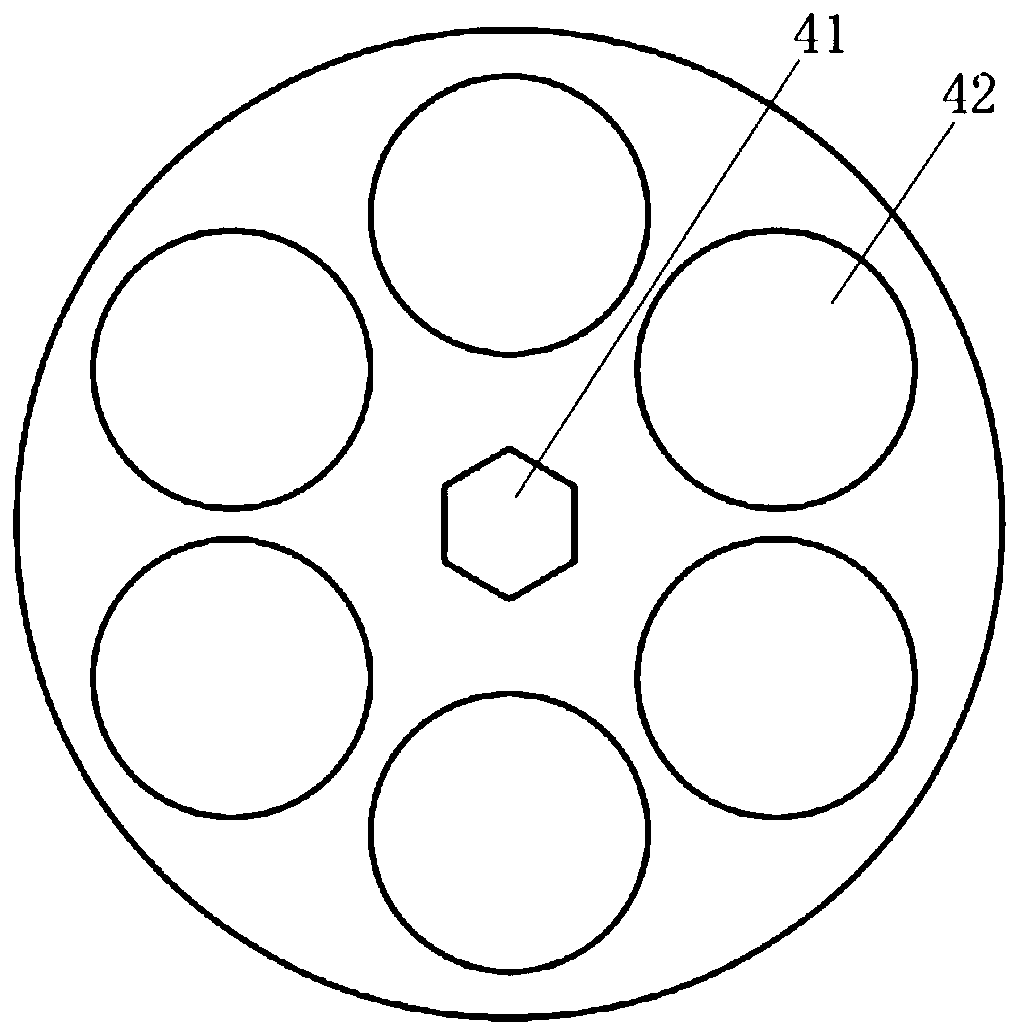

Linear spot scanning laser chemical micro-thruster

ActiveCN111022215ASatisfy micro-satellite attitude controlMeet needsRocket engine plantsCombustion chamberLaser scanning

The invention relates to a linear spot scanning laser chemical micro-thruster capable of providing mN micro-thrust. The micro-thruster comprises a photosensitive propellant, a cylindrical combustion chamber, a Laval nozzle, a rotary steering gear and a linear spot laser. The rotary steering engine drives the linear spot laser to perform 360-degree stepping rotation, the linear spot laser scans andignites the photosensitive propellant in the cylindrical combustion chamber, and fuel gas is sprayed out via the Laval nozzle and generates mN thrust. The rotary steering gear can adjust the rotationangle and rotation speed, so that laser scanning speed of a linear spot is adjusted, the photosensitive propellant can be subjected to non-self-sustained combustion under laser irradiation, combustion and extinguishing of the propellant are achieved by turning on or turning off the laser, and thus, repeated start of thrust is achieved. The micro-thruster has small size and low weight, and can generate mN thrust under the vacuum condition, and the power demand of attitude control and orbit change of microsatellites is met.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

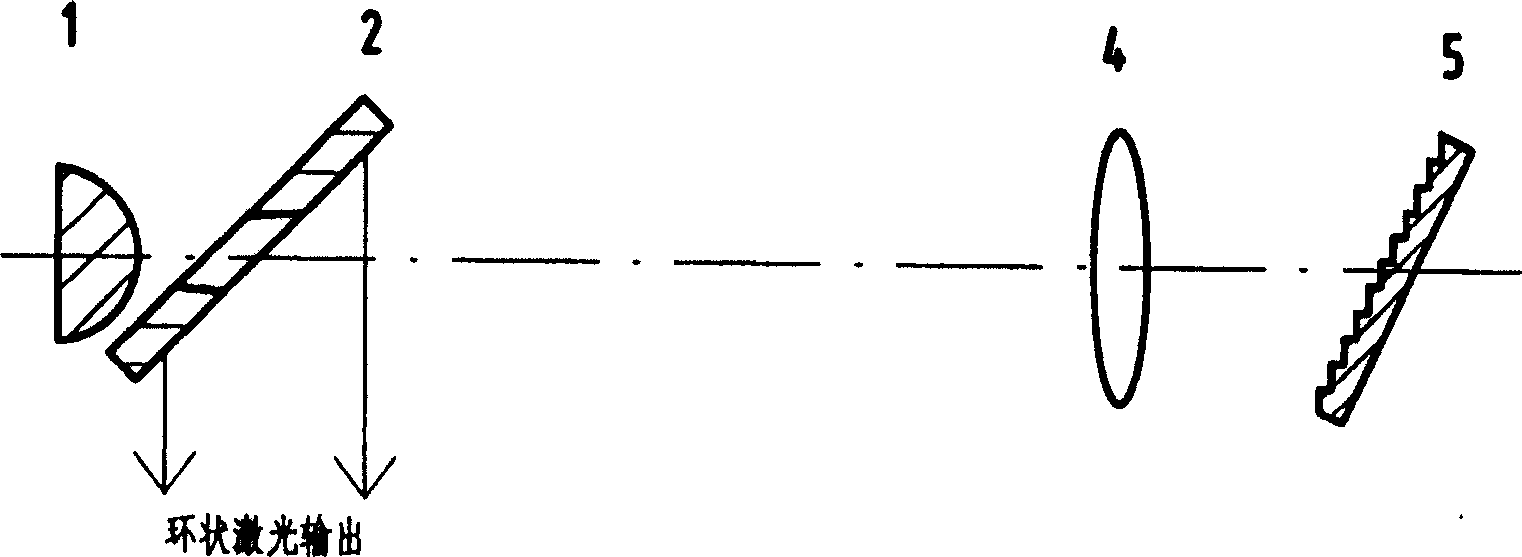

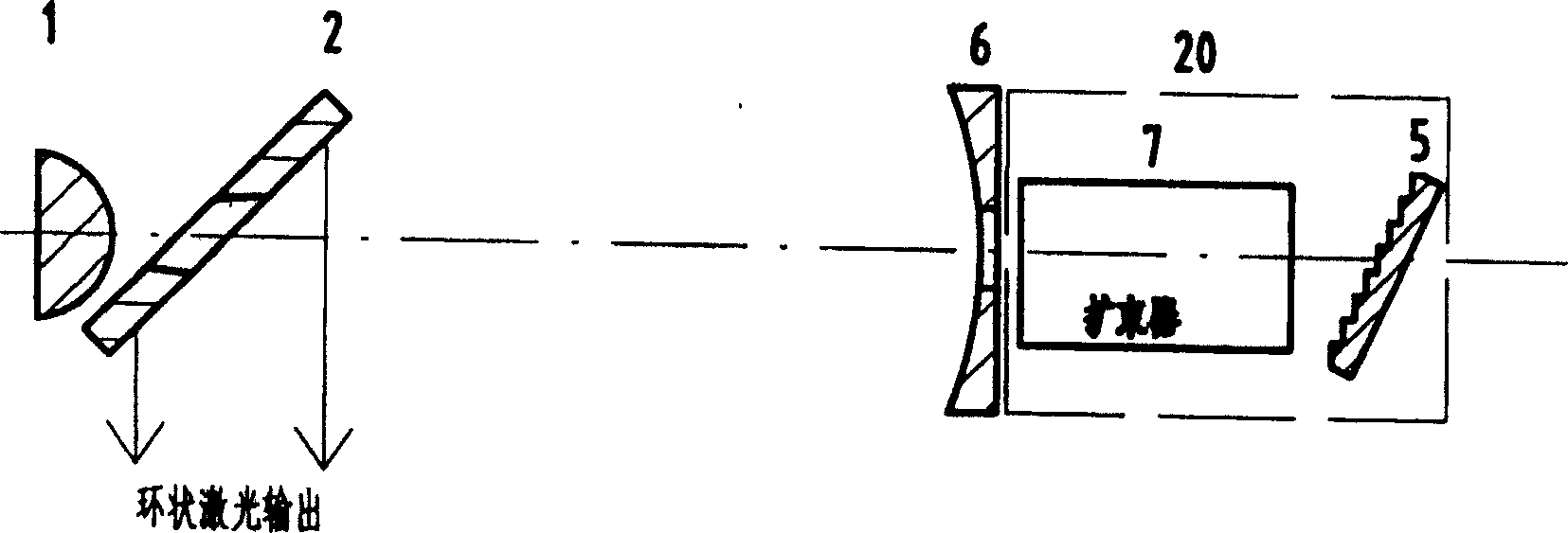

Grating-selected quick tuning laser resonant cavity

InactiveCN100466402CFast tuningLarge tuning rangeOptical resonator shape and constructionAutomatic controlPlane mirror

The invention is of a grating election rapid tunable laser resonator, involving laser technology, the laser resonator with servo-motor-driven rotary turntable grating and accurate positioning and achieve grating election of the rapid line tunable lasers. The laser resonator cavity of the laser output mirror, grating, grating turntable, the servo motor, servo motor drive modules and control modules and other components, which is part of the output mirror reflection of the transmission type spherical mirror or plane mirror, grating for the plane or spherical reflecting diffraction grating. Total output mirror and a grating optical axis, and the normal and the optical axis grating into the quasi-rectangular. This invention achieved a grating election rapid tuning of the laser output, tuning speed, tuning range, high precision tuning advantages. Apply to pulse CO2 laser pulse CO laser, pulsed HF / DF and other tunable laser pulse laser, laser atmospheric detection, laser chemistry, laser processing, and other fields have a broad application prospects.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

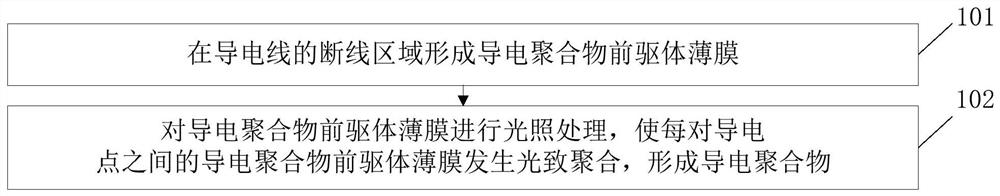

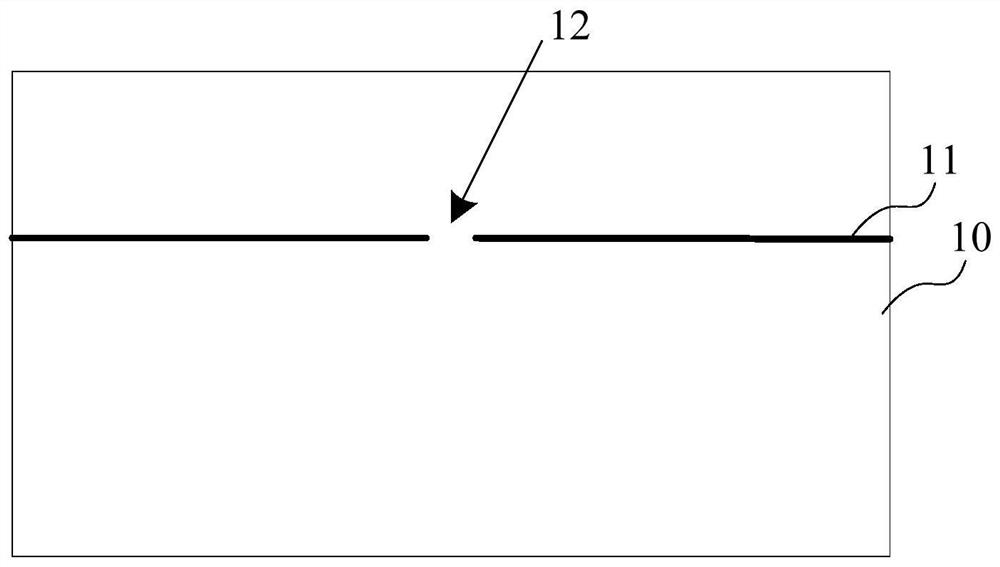

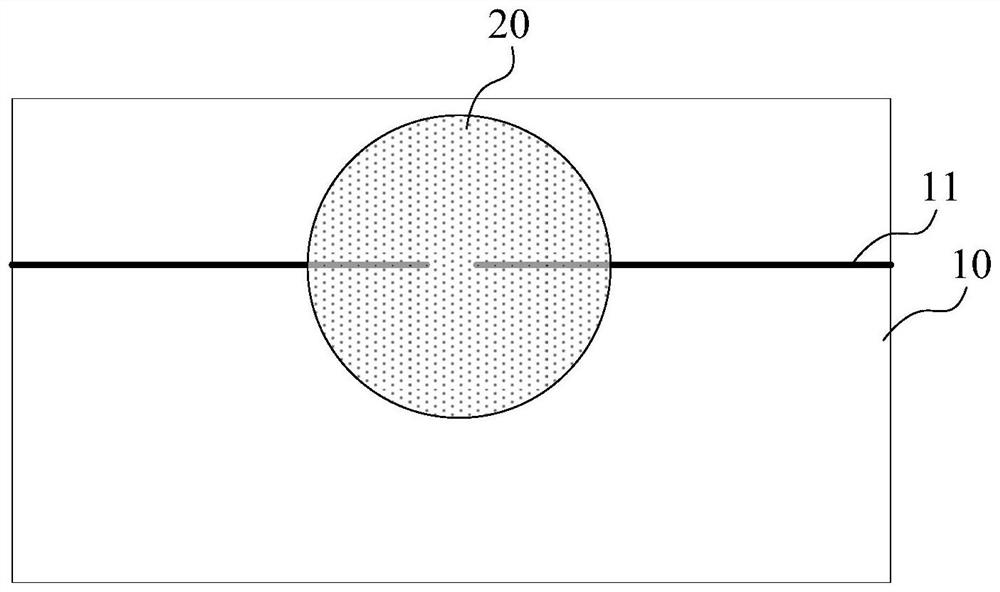

Disconnection repair method, substrate and display device

ActiveCN109307964BAchieve fixReduce repair costsConductive materialSolid-state devicesConductive polymerLight treatment

Owner:BOE TECH GRP CO LTD

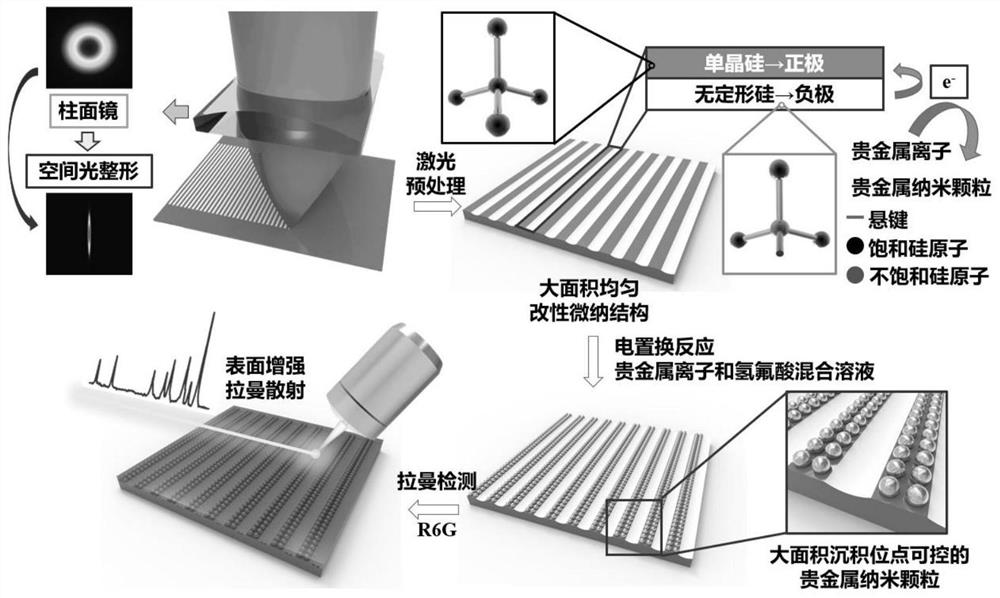

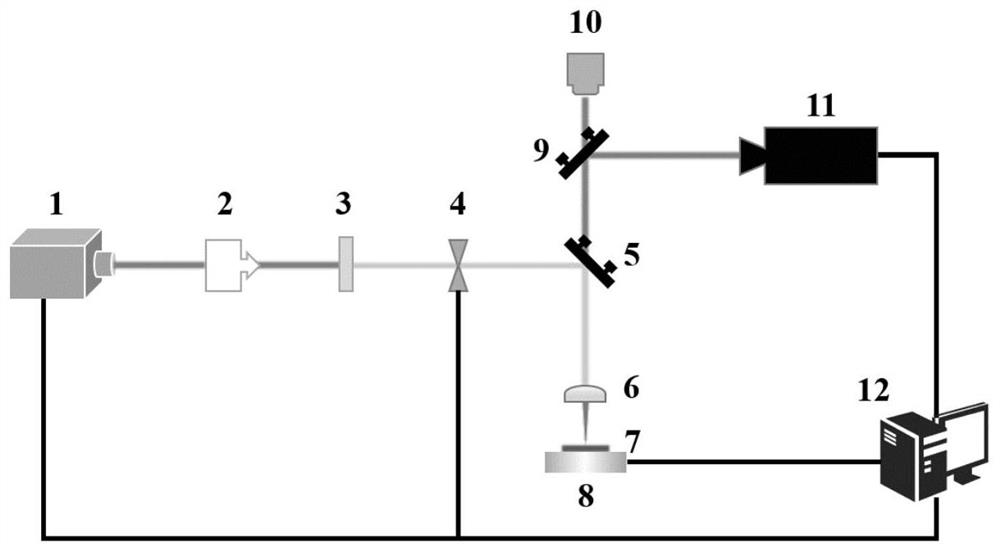

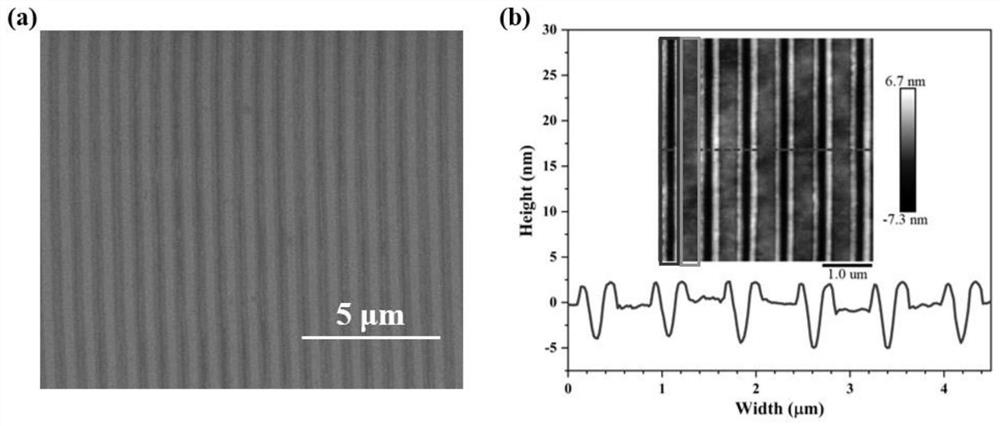

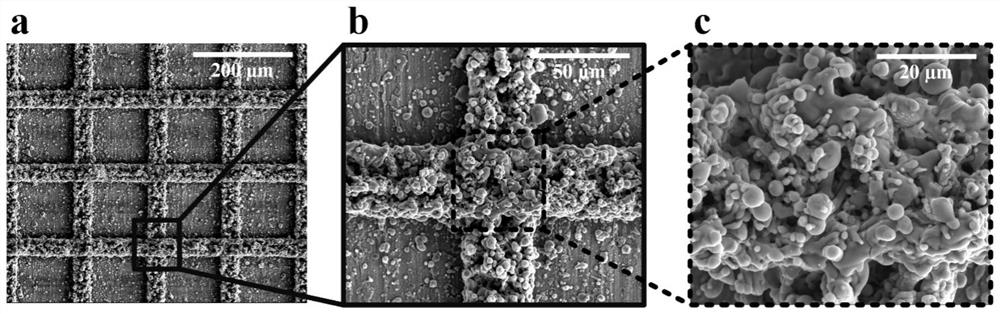

Method for preparing controllable noble metal nanoparticles through femtosecond laser regulation and control electric replacement reaction

PendingCN113201729AImprove processing efficiencyEfficient formationNanotechnologyLiquid/solution decomposition chemical coatingFree electron densityNano structuring

The invention discloses a method for preparing controllable noble metal nanoparticles through femtosecond laser regulation and control electric replacement reaction, and belongs to the field of laser chemistry. The implementation method comprises the following steps that 1, the local free electron density on the surface of monocrystalline silicon is regulated and controlled through cylindrical mirror spatial light-shaped femtosecond laser, periodic amorphous state transformation is generated, and a large-area uniform modified micro-nano structure is efficiently formed; and 2, noble metal ions is reduced by performing galvanic replacement reactions, single crystal silicon and the amorphous silicon which are adjacent can form a positive and negative electrode structure similar to a primary battery, and due to the fact that the amorphous silicon formed through laser induction contains a large number of dangling bonds, the chemical reducibility of the amorphous silicon is higher, the amorphous silicon as a negative electrode loses electrons in the electric replacement reaction, electrons are transferred to the surface of monocrystalline silicon serving as a positive electrode,noble metal nanoparticles are only selectively deposited in an area which is not modified by laser, the large-area precious metal nanoparticles with controllable deposition sites are simply, conveniently and efficiently prepared, and the application performance of the nanoparticles is improved by regulating and controlling the size and distribution density of the nanoparticles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

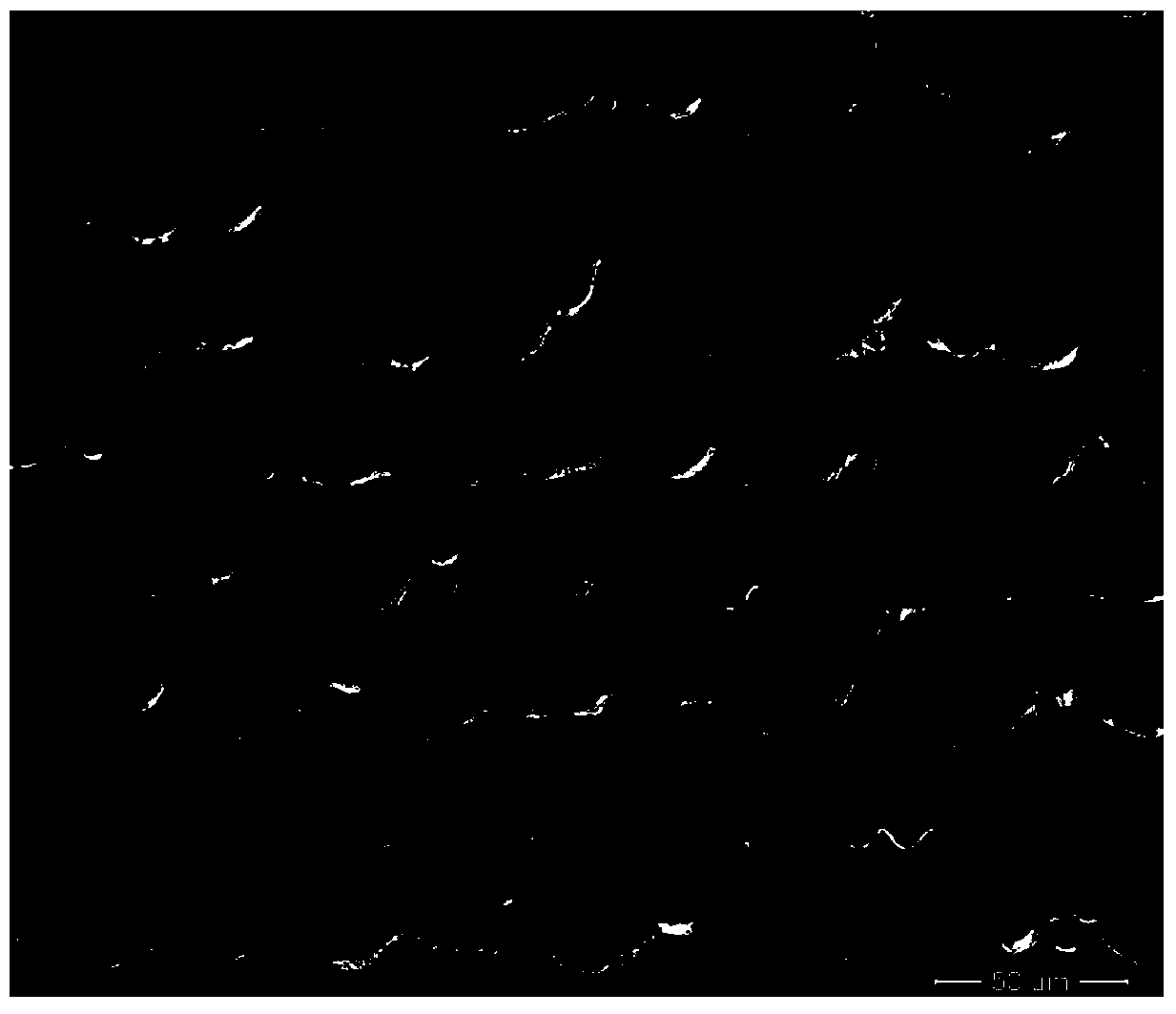

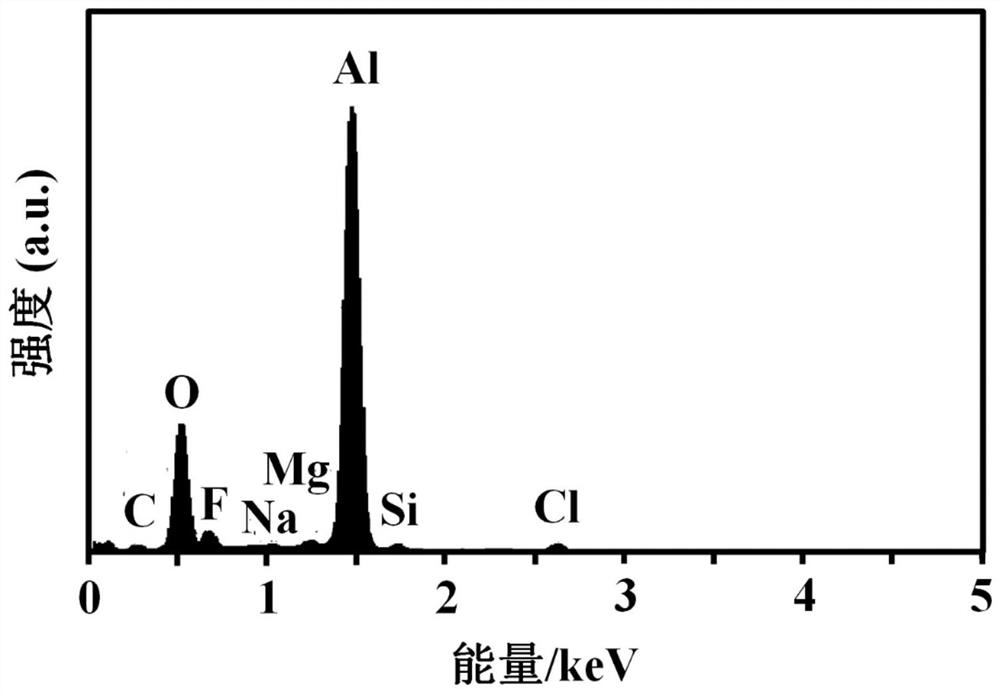

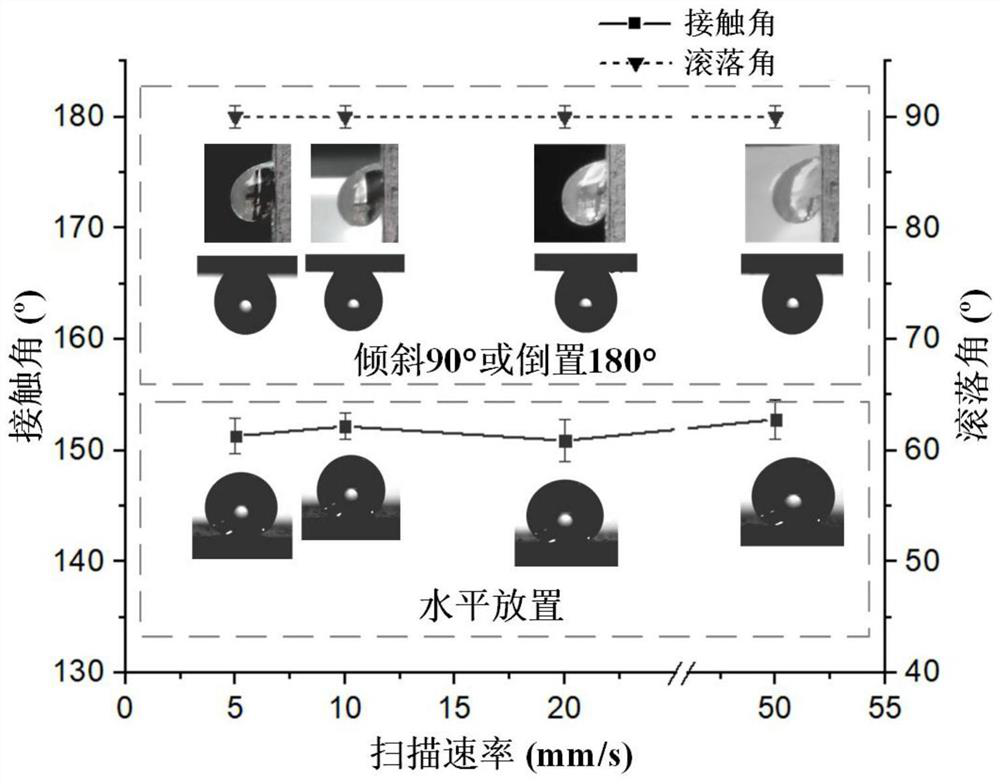

Preparation method of high-adhesion superhydrophobic surface based on laser chemical composite process

ActiveCN113275223BImprove production efficiencyImprove adhesionPretreated surfacesMetallic material coating processesNano structuringSilanes

The invention discloses a preparation method of a high-adhesion super-hydrophobic surface based on a laser chemical composite process, which improves the preparation efficiency. The method includes the following steps: step 10) cleaning the substrate; step 20) laser surface microtexture: using a laser beam to process micro-nano structures on the surface of the alloy substrate, and then ultrasonically cleaning in absolute ethanol; step 30) silane solution infiltration: the step 20) The treated alloy substrate is soaked in a mixed solution of 1H, 1H, 2H, 2H-tetrahydroperfluorooctyltrichlorosilane and ethanol, then taken out and placed in a nitrogen stream to dry, and finally placed in an oven Medium baking; Step 40) Sodium chloride solution soaking: soak the alloy substrate treated in step 30) in a sodium chloride solution, then take it out and clean it with deionized water, and finally place it in a nitrogen stream to dry it to obtain High adhesion superhydrophobic surface.

Owner:SOUTHEAST UNIV

A line-selecting annular cavity for chemical laser devices

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High power tunable CO2 laser

The CO2 laser includes one spherial reflector, one CO2 laser discharging gain region, and one Fabry-Perot modulator and features that the Fabry-Perot modulator is as one terminal reflector of the laser resonant cavity and for laser power to be transmitted to couple output. With simple structure and stable performance, the CO2 laser may be applied in laser chemistry, atmosphere transmission, material machining and other fields.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

A method for rapidly preparing ultra-thin ceramic sheets

ActiveCN108893723BIncrease deposition rateReduce the temperatureChemical vapor deposition coatingChemical vapor depositionEnergy consumption

The invention relates to a method for quickly preparing an ultrathin ceramic chip. The method comprises the following steps: utilizing a laser chemical vapor deposition technique to take a corresponding metallic organic source as a precursor raw material and deposit a uniform ceramic layer on a specific substrate under an activating effect of laser, and then separating the substrate from the prepared ceramic layer in the manner of ablating or grinding, thereby acquiring a single high-compactness specific ultrathin ceramic chip. The method not only can greatly reduce the sintering temperature of the ceramic chip and is beneficial to reducing energy consumption, but also is simple in posttreatment process, short in production period, lower in cost and huge in application prospect in the aspect of industrial production.

Owner:WUHAN XINGUI TECH QIANJIANG CO LTD

Rotation-driven charge structure for combined laser chemical propulsion

The invention relates to a rotary driving loading structure for a laser chemical combined propeller. The structure comprises a rotary disc, a rotary steering engine and at least two combustion rooms,wherein the rotary steering engine is connected to the rotary disc and is used for driving the rotary disc to rotate; the combustion rooms are hermetically and fixedly connected to the rotary disc, and the rotary disc rotates to drive the combustion rooms to rotate; each of the combustion rooms is provided with a solid propellant; and the combustion rooms are arranged in parallel, and the rotary steering engine is arranged parallel to the combustion rooms. The rotary driving loading structure for the laser chemical combined propeller provided by the invention is small in size and light in weight, and can meet the power demand on micro satellite orbit control.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com