Rotation-driven charge structure for combined laser chemical propulsion

A technology of rotary drive and thruster, which is applied in the direction of jet propulsion devices, machines/engines, rocket engine devices, etc. It can solve the problems of complex structure and heavy weight of the engine, achieve light weight, high space utilization rate, and increase the amount of charge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

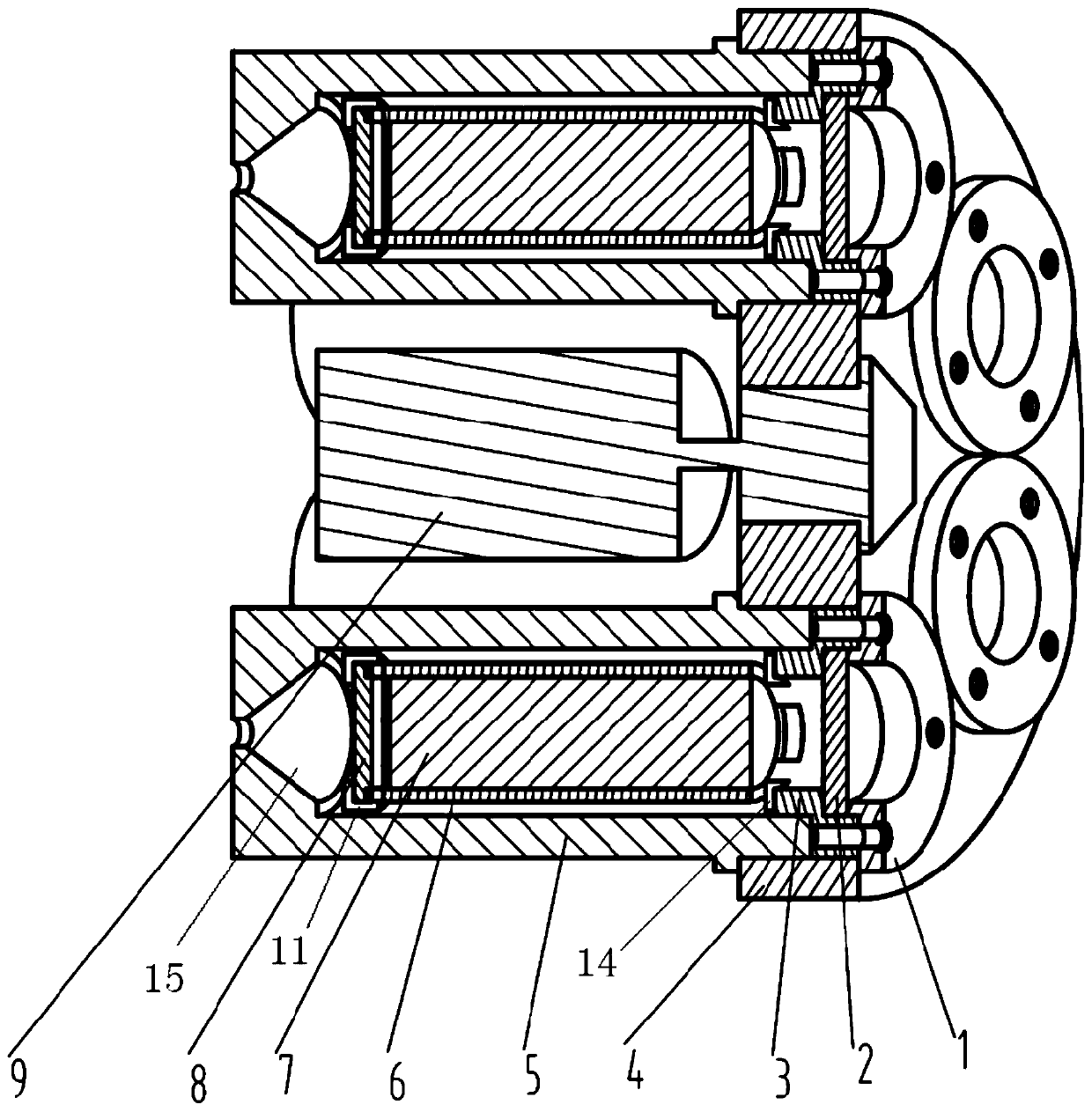

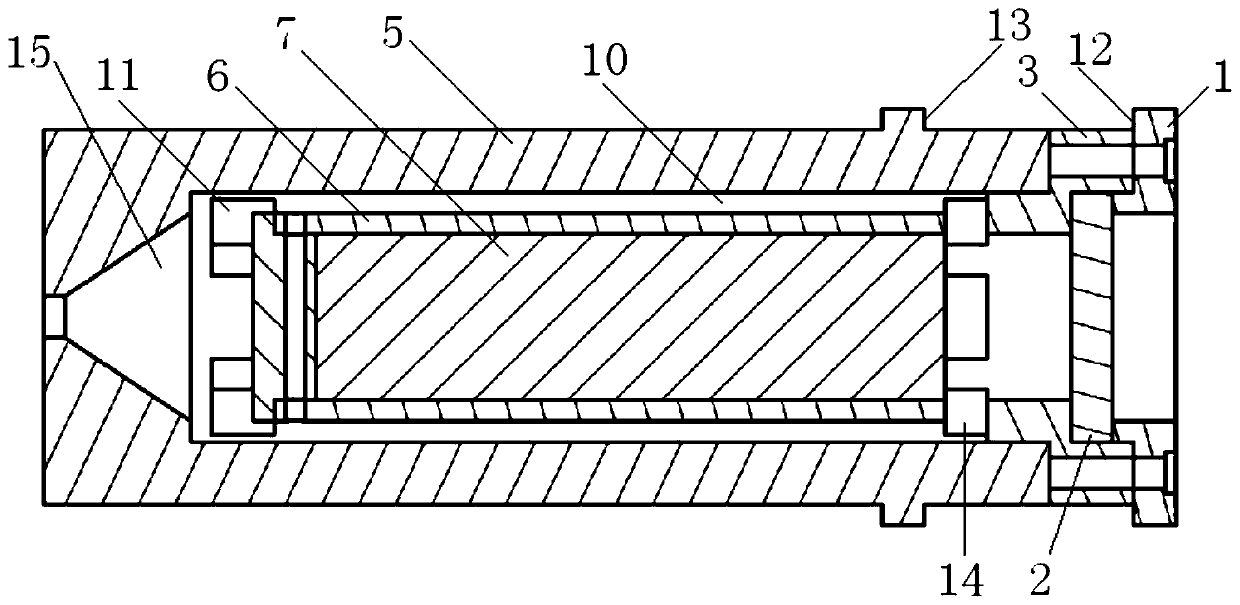

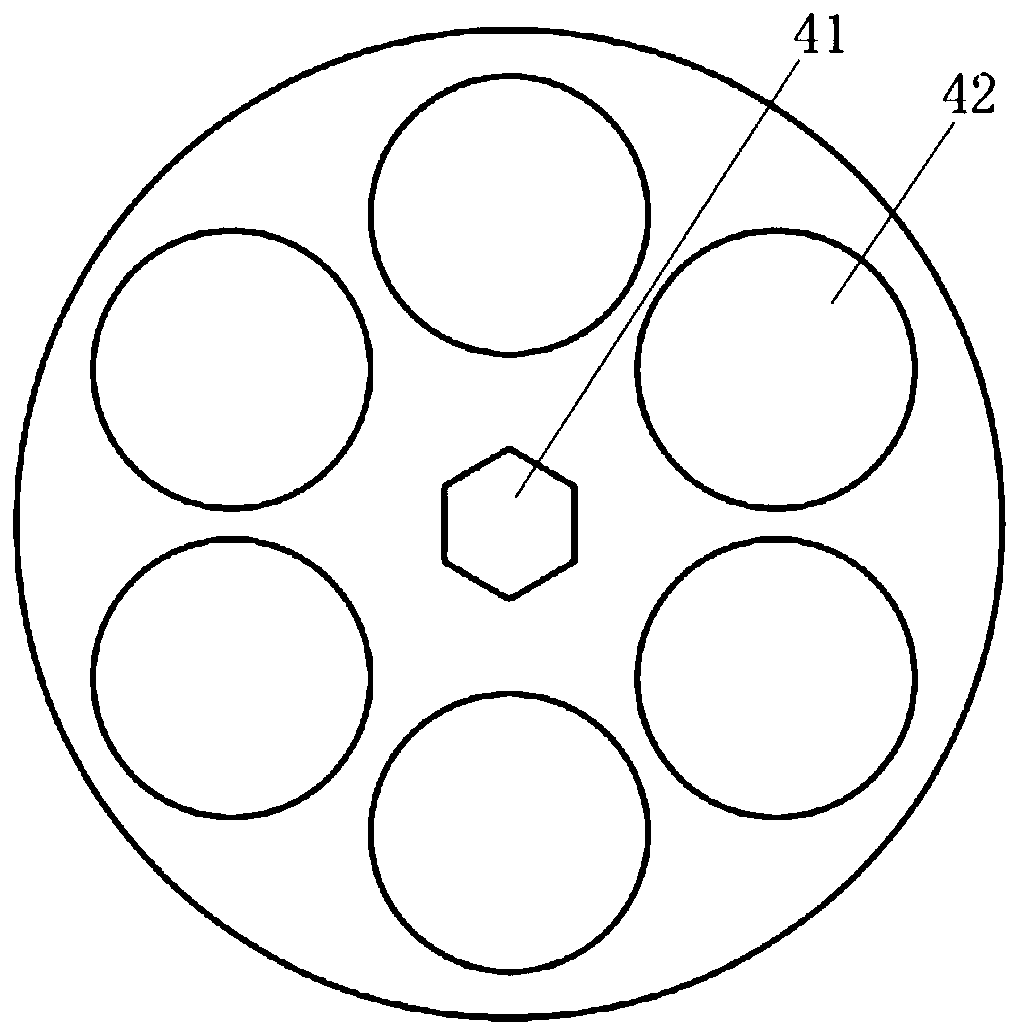

[0026] The following will combine Figure 1 to Figure 4 A further detailed description will be made on the rotation-driven charge structure used in the combined laser chemical thruster of the present invention.

[0027] figure 1 Shown is a cross-sectional view of a rotary-driven charge structure for a combined laser chemical thruster according to a preferred embodiment of the present invention; figure 2 Shown is a cross-sectional view of a single combustion chamber in a preferred embodiment of the present invention.

[0028] see figure 1 and figure 2 , the rotary-driven charge structure for the combined laser chemical thruster of this embodiment includes a turntable 4, a rotary steering gear 9 and at least two combustion chambers;

[0029] The rotary steering gear 9 is connected to the turntable 4, and the rotary steering gear 9 is used to drive the turntable 4 to rotate;

[0030] The combustion chamber is sealed and fixedly connected with the turntable 4, and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com