Linear spot scanning laser chemical micro-thruster

A technology of micro-propeller and linear light spot, which is applied in the directions of jet propulsion, machine/engine, rocket engine, etc., to achieve the effect of reducing structural mass, improving system safety, and reducing system complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

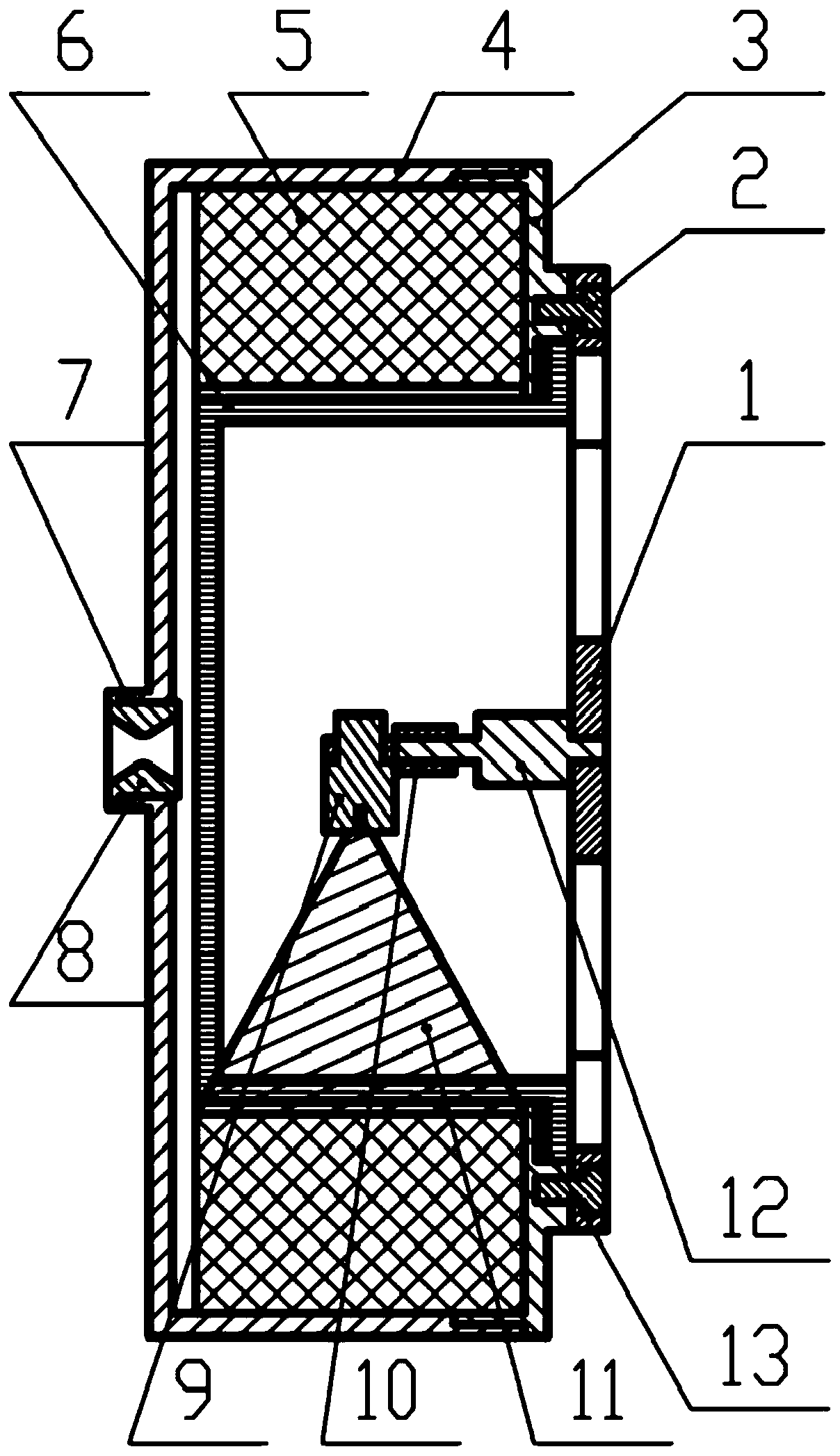

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

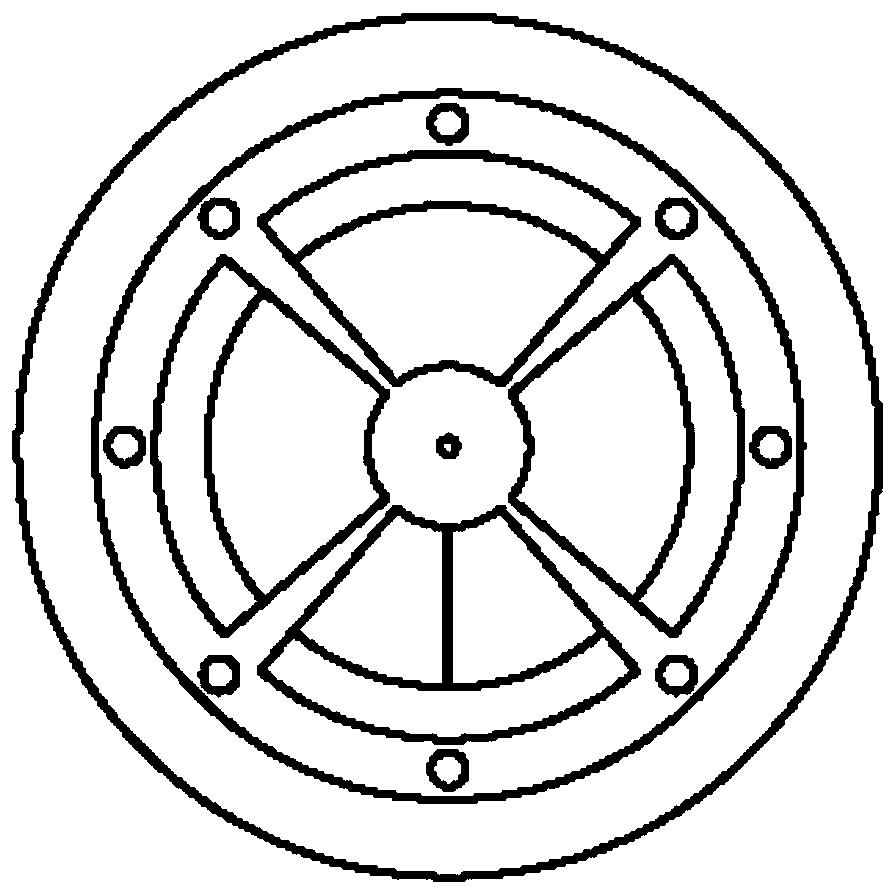

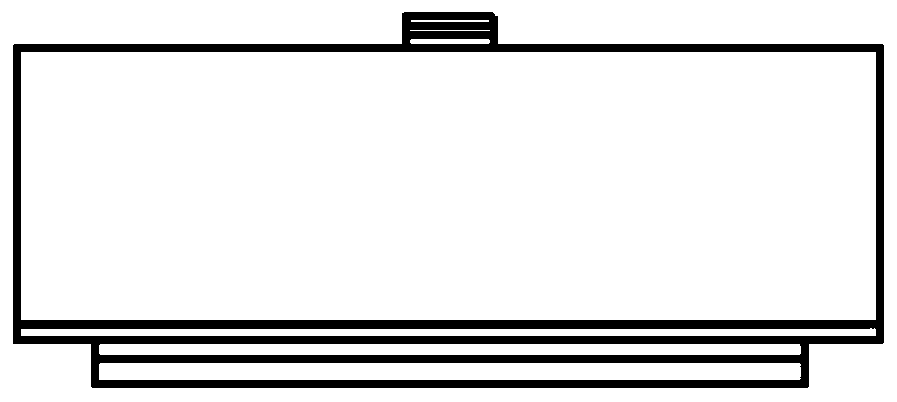

[0034] The invention provides a laser chemical micro-propeller of line-spot scanning type. The propeller uses laser light to control the combustion of photosensitive propellants, and the combustion gas products are accelerated and ejected through the internal flow field of the engine, thereby generating mN-level thrust. The specific implementation scheme is: the laser chemical micro-propeller of the line spot scanning type is composed of a photosensitive propellant, a combustion chamber, a Laval nozzle, a rotating steering gear and a line spot laser; High-speed stepping and rotating motion, the line spot laser scans the photosensitive propellant, and the photosensitive propellant burns non-self-sustainingly in the combustion chamber in the irradiated area of the line spot laser, and the gas generated by the combustion is ejected thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com