Device and method for preventing crystallization of deposition gas in laser chemical vapor deposition

A technology of chemical vapor deposition and deposition gas, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., and can solve problems such as pipeline blockage, non-disclosure, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

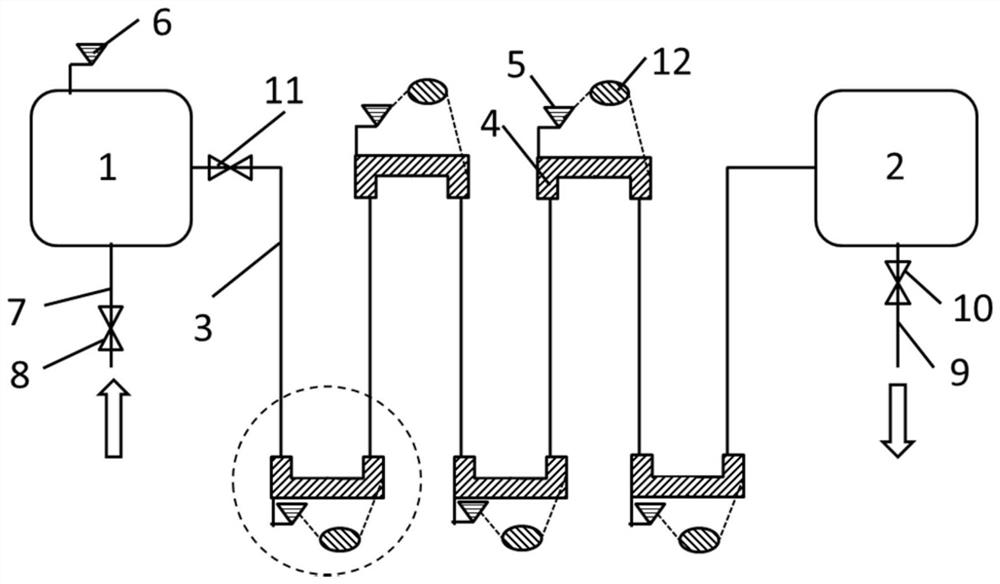

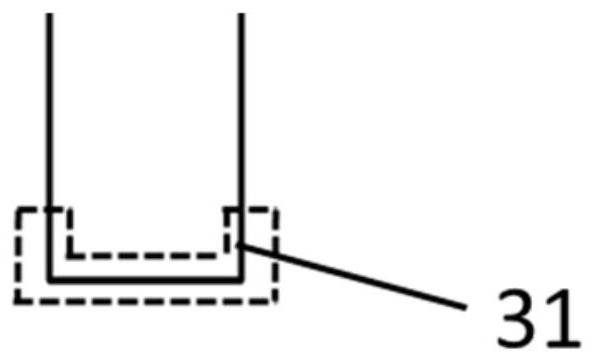

[0045] This embodiment provides a device and method for preventing crystallization of deposition gas in laser chemical vapor deposition, such as figure 1 and figure 2 As shown, the device includes: a deposition gas storage container 1, which is used to supply the deposition gas required for laser chemical vapor deposition; a reaction chamber 2, which is used to carry out the laser chemical vapor deposition process; a pipeline 3, which communicates with the deposition gas The storage container 1 and the reaction chamber 2 are used to transport the deposition gas from the deposition gas storage container 1 to the reaction chamber 2. Along the flow direction of the deposition gas, the pipeline 3 includes five temperature loss regions 31; a temperature maintaining device 4, which is arranged along the pipeline 3, and is used to keep the deposition gas in the pipeline 3 in a continuous gasification state, and the temperature maintaining There are five devices 4, which are corresp...

Embodiment 2

[0050] This embodiment provides a device and method for preventing the crystallization of deposition gas in laser chemical vapor deposition, which is the same as that of Embodiment 1. figure 1 and figure 2 Similarly, the device includes: a deposition gas storage container 1 for supplying the deposition gas required for laser chemical vapor deposition; a reaction chamber 2 for carrying out the laser chemical vapor deposition process; a pipeline 3 connected to the deposition gas storage The container 1 and the reaction chamber 2 are used to transport the deposition gas from the deposition gas storage container 1 to the reaction chamber 2. Along the flow direction of the deposition gas, the pipeline 3 It includes seven temperature loss areas 31; a temperature maintaining device 4, which is arranged along the pipeline 3, and is used to keep the deposition gas in the pipeline 3 in a continuous gasification state, and the temperature maintaining device 4 is seven, which are corres...

Embodiment 3

[0055] This embodiment provides a device and method for preventing the crystallization of deposition gas in laser chemical vapor deposition, which is the same as that of Embodiment 1. figure 1 and figure 2 Similarly, the device includes: a deposition gas storage container 1 for supplying the deposition gas required for laser chemical vapor deposition; a reaction chamber 2 for carrying out the laser chemical vapor deposition process; a pipeline 3 connected to the deposition gas storage The container 1 and the reaction chamber 2 are used to transport the deposition gas from the deposition gas storage container 1 to the reaction chamber 2. Along the flow direction of the deposition gas, the pipeline 3 It includes three temperature loss areas 31; a temperature maintaining device 4, which is arranged along the pipeline 3, and is used to keep the deposition gas in the pipeline 3 in a continuous gasification state, and the temperature maintaining device 4 is three, which are corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com