Novel technology and equipment for preparing various functional and structural thin films at high speed

A high-speed, functional technology, applied in the field of coating and surface processing, can solve the problems of reducing the activation energy of the reaction between raw material molecules and slow deposition rate, and achieve the effect of high raw material utilization and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

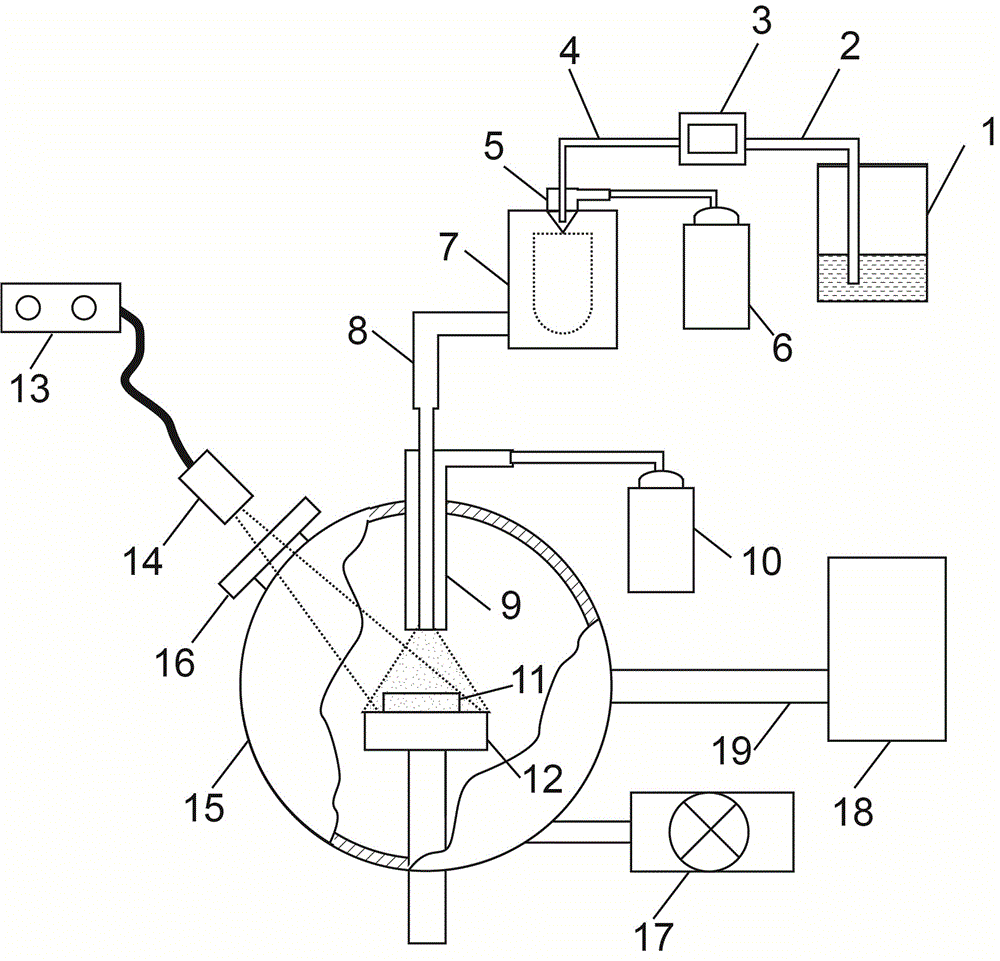

[0016] When the equipment is running, the reaction chamber 15 will reduce the pressure of the chamber 15 to the required value under the action of the vacuum pump 17 to provide necessary conditions for the smooth progress of the reaction.

[0017] The liquid raw material in the liquid raw material tank 1 is extracted by the liquid raw material conveying part 3 through the liquid raw material extraction pipe 2, and is continuously and stably sent to the pressure chamber 5 through the liquid raw material conveying pipe 4. The gas in the carrier gas storage tank 6 generates pressure in the pressure chamber 5, and quickly presses out the liquid raw material that has been pressed into the pressure chamber 5, and the liquid raw material is thus atomized into small droplets. When the atomized small droplets are sprayed to the wall of the spray atomization-multiple eutectoid volatilization chamber 7, the solvent in the small droplets volatilizes quickly due to the thermal effect of the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com