Aerodynamic high-performance aerofoil for aircraft

An aerodynamic and high-performance technology, applied in the field of aircraft airfoils, can solve the problems of difficult application and immature application of flow control technology, and achieve the effects of high safety, light weight and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

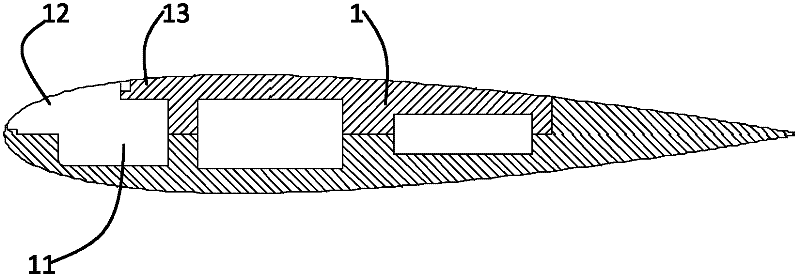

Embodiment 1

[0023] see figure 1 , the aerodynamic high-performance airfoil 1 used for the aircraft in this embodiment selects the NACA0015 airfoil. The chord length of the airfoil 1 is 800mm, and the spanwise width of the experimental part is 200mm. The airfoil 1 has a cavity 11 at the leading edge 2.2 mm to 126.4 mm, and an elastic structure 12 covering the cavity 11 . The elastic structure 12 is an elastic skin 12 . The cavity 11 is provided with an opening on the suction surface 13 of the airfoil 1 , the elastic skin 12 covers the surface of the opening, and the periphery of the elastic skin 12 is fixed on the airfoil 1 . In the specific implementation process, the elastic skin 12 is on the suction surface 13 of the airfoil 1. Since the elastic skin 12 is a flexible material, it has a strong fluid-solid coupling with the incoming flow. On the one hand, the elastic skin 12 Deformation will occur under load, on the other hand, the deformation of the elastic skin 12 will in turn affect...

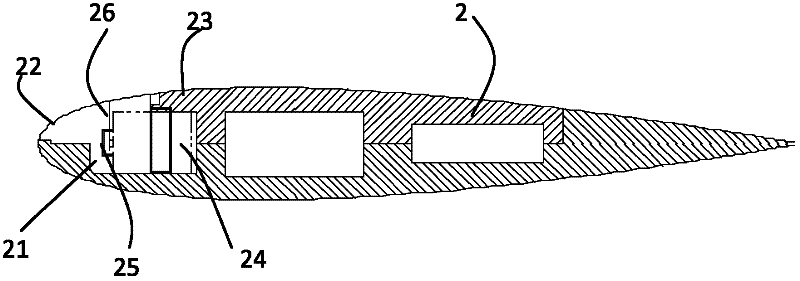

Embodiment 2

[0025] see figure 2 , the aerodynamic high-performance airfoil 2 used for the aircraft in this embodiment also selects the NACA0015 airfoil. The airfoil 2 has a cavity 21 at its leading edge 2.2 mm to 126.4 mm, and an elastic structure 22 covering the cavity 21 . The elastic structure 22 is an elastic skin 22 . The cavity 21 has an opening on the suction surface 23 of the airfoil 2 , the elastic skin 22 covers the surface of the opening, and the surrounding of the elastic skin 22 is fixed on the airfoil 2 . The airfoil 2 is also provided with an exciter 24 , a fixing device 25 and a spring 26 accommodated in the cavity 21 . The vibration amplitude of the vibrator 24 is 5 mm, and the vibration frequency can vary from 0 Hz to 200 Hz. One end of the spring 26 is connected to the exciter 24 by a fixing device 25 , and the other end of the spring 26 is fixed at the center of the elastic skin 22 . In this embodiment, the vibrator 24 is set at any excitation frequency between 0 ...

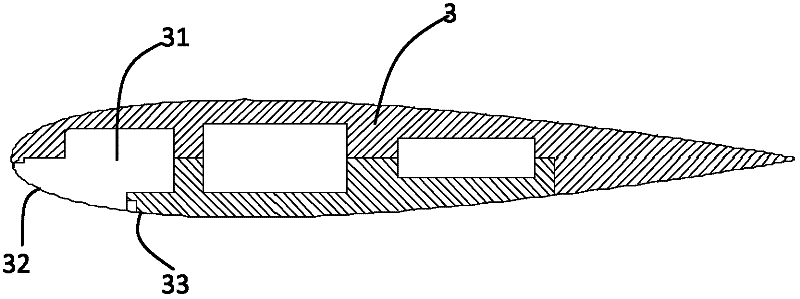

Embodiment 3

[0027] see image 3, the aerodynamic high-performance airfoil 3 used for aircraft in this embodiment is provided with a cavity 31 and an elastic skin 32, which are basically the same structure as in Embodiment 1. The difference is that the cavity 31 is provided with an opening on the pressure surface 33 of the airfoil 3 , and the elastic skin 32 covers the surface of the opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com