Fuel-gas-heating directional solidification furnace

A technology of directional solidification furnace and gas heating, which is applied in self-solidification, polycrystalline material growth, crystal growth, etc., can solve the problems of high operating cost and single selection of heat source, and meet the requirements of the process, save energy, and the heating process can be control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

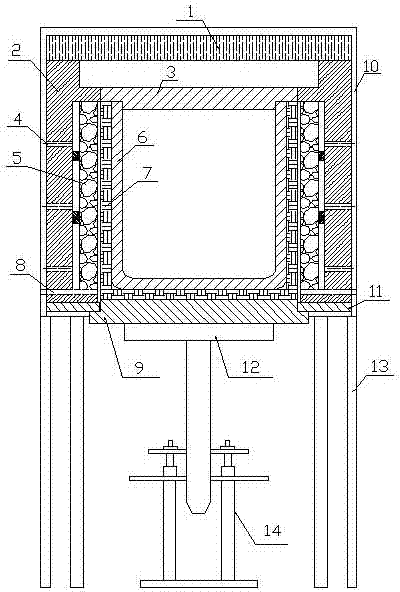

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0019] see figure 1 , a gas-fired heating directional solidification furnace in this embodiment, a supporting steel base 13 is provided, a lifting mechanism 14 is provided at the middle of the bottom of the supporting steel base 13, and the furnace body is above the supporting steel base 13.

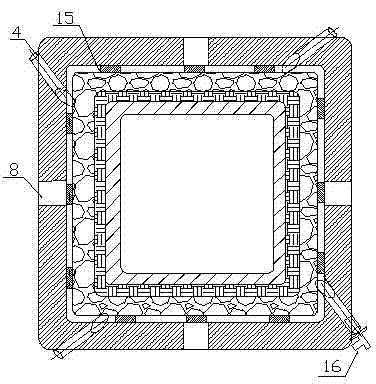

[0020] The core of the heating zone in the furnace body is a square quartz crucible 6, and the crucible 6 is covered with a crucible protective cover 7 made of mullite material. The top of the crucible 6 is provided with a crucible cover 3 of quartz material having the same shape as the opening of the crucible 6 .

[0021] The ceramic foam layer 5 is arranged along the outer four sides of the crucible protective layer 7, and side wall positioning bricks 15 are installed between the furnace wall 2 and the ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com