High voltage and ultra-high voltage direct current (DC) cross-linked polyethylene insulated sea electric power cable

A submarine power cable and cross-linked polyethylene technology, which is applied to power cables, submarine cables, and power cables with shielding/conducting layers, etc., can solve problems such as high cost, difficulty in manufacturing anti-corrosion plastic-coated steel wires, and difficulty in laying construction. , to achieve the effect of convenient subsea buried construction, elimination of the corrosion effect of polarized electric field, low manufacturing cost and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

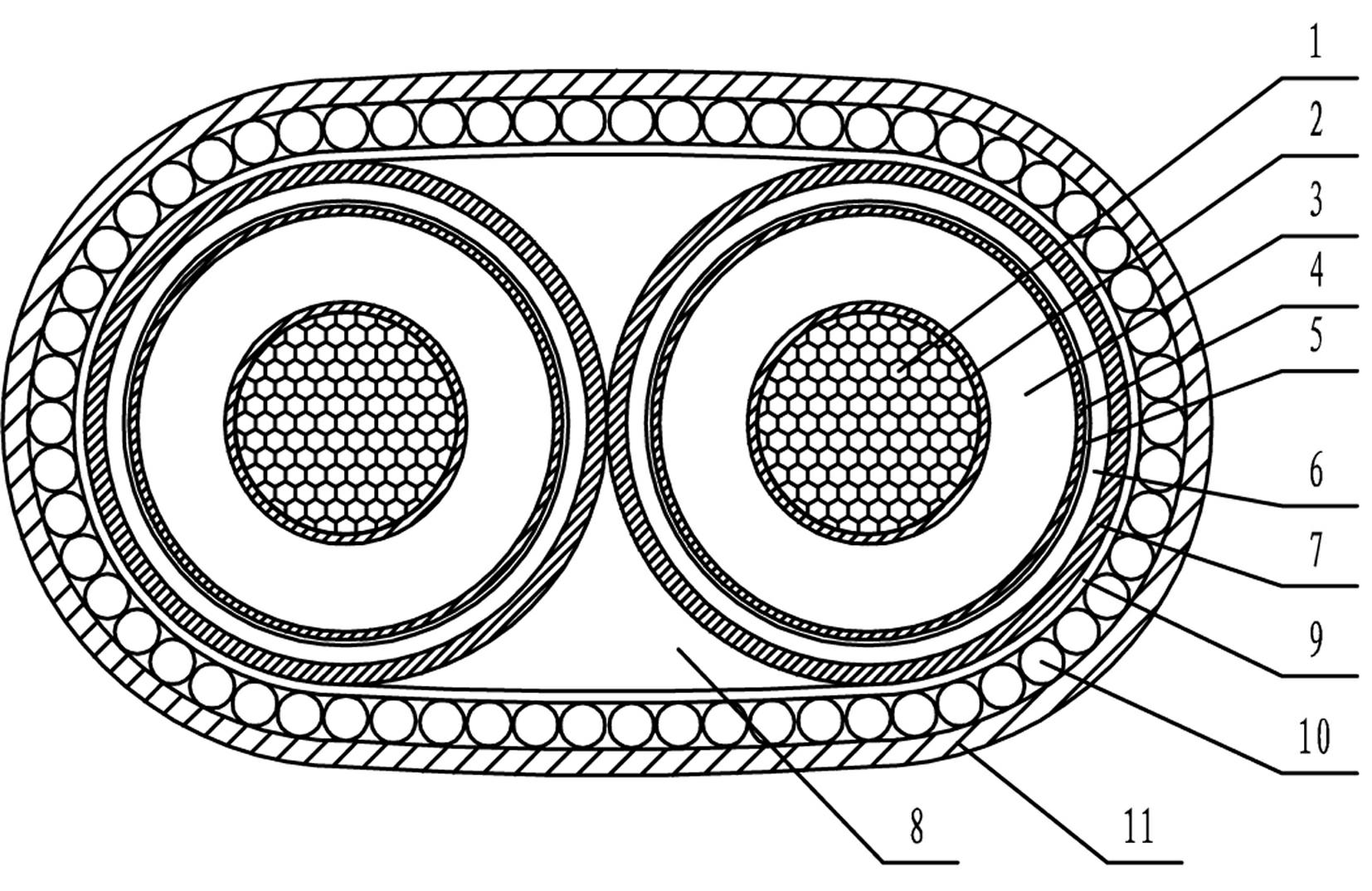

[0020] Embodiment 1: A high-voltage, ultra-high-voltage DC cross-linked polyethylene insulated submarine power cable, the outer layer 11 is a metal armor layer 10, the metal armor layer 10 is a cable binding tape 9, and the forward DC power transmission cable Cores and negative DC power transmission cable cores are bundled with cable binding tape 9, and the positive and negative DC power transmission cable cores are water-blocking conductor 1, conductor shielding layer 2, insulating layer 3, and insulating shielding layer from the inside to the outside. 4. The semiconducting resistive water buffer layer 5 and the metal shielding layer 6 are filled with filling strips 8 between the cores of the positive DC power transmission cable and the cores of the negative DC power transmission cable.

[0021] The insulating layer 3 is made of modified DC cross-linked polyethylene insulating material. Submarine power cables with cross-linked polyethylene as insulating material have good mec...

Embodiment 2

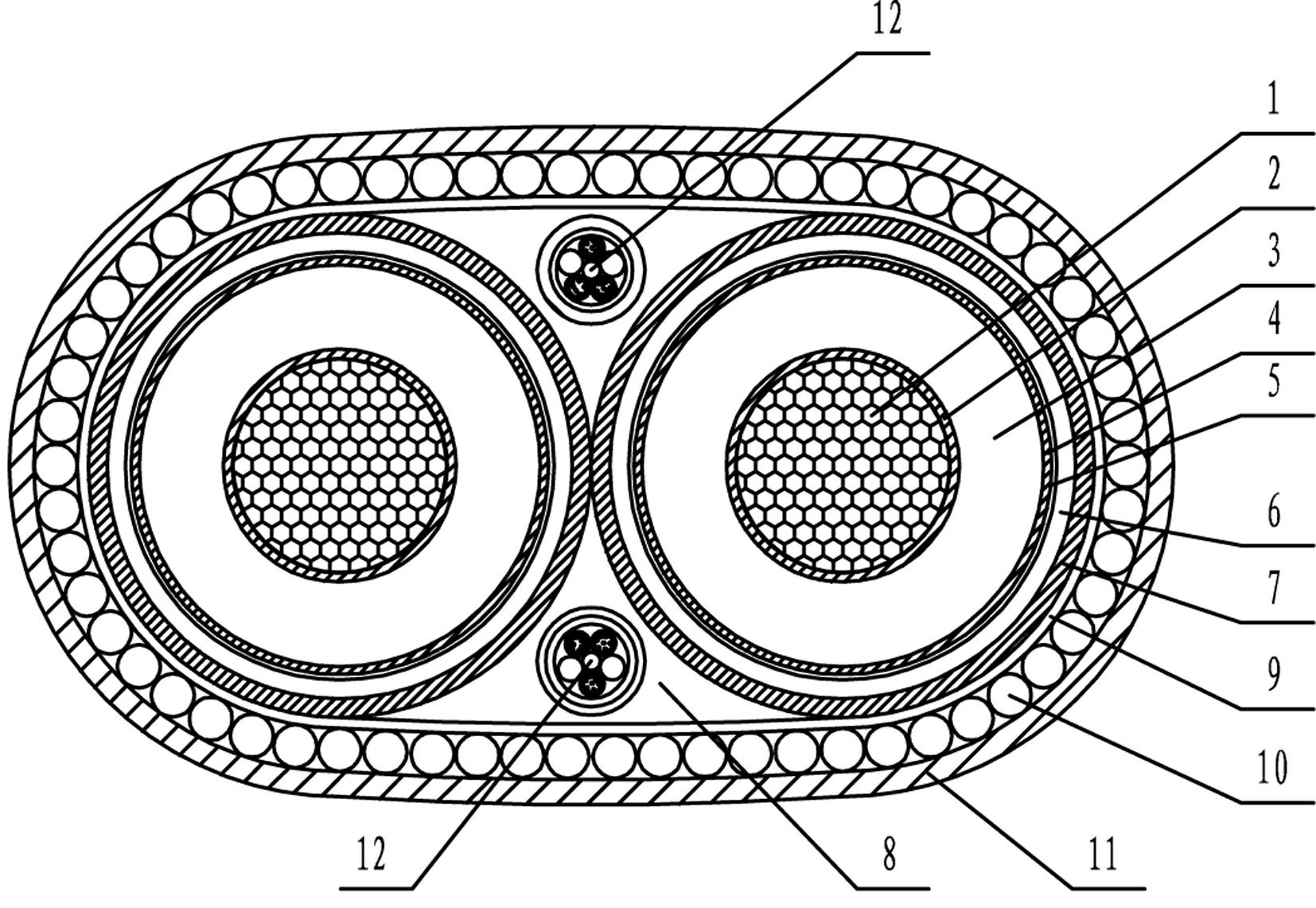

[0029] figure 2 is another technical design application example of the present invention: it and figure 1 The main difference of the scheme is that one or two submarine optical cable units 12 are added in the cable forming space of the two cable cores in the positive and negative direct current transmission core assembly cable forming process. It constitutes a ±100~400kV cross-linked polyethylene insulation, lead sheath shielding + semi-conductive plastic reinforced sheath, thick steel wire armor, two-core DC transmission photoelectric composite submarine power cable.

[0030] figure 2 Implementation Description: A two-core DC transmission optoelectronic composite submarine power cable for ±100-400kV cross-linked polyethylene insulation, lead sheath shielding + semi-conductive plastic reinforced sheath, thick steel wire armor. Such as figure 2 As shown, the inner layer to the outer layer respectively include the water-blocking conductor 1 of the cable, the conductor shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com