Backlight light-emitting diode (LED) flat light source

A technology of flat light source and light diffusion plate, which is applied in the field of LED light source, can solve the problem of high cost, and achieve the effect of low cost, high light output efficiency, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

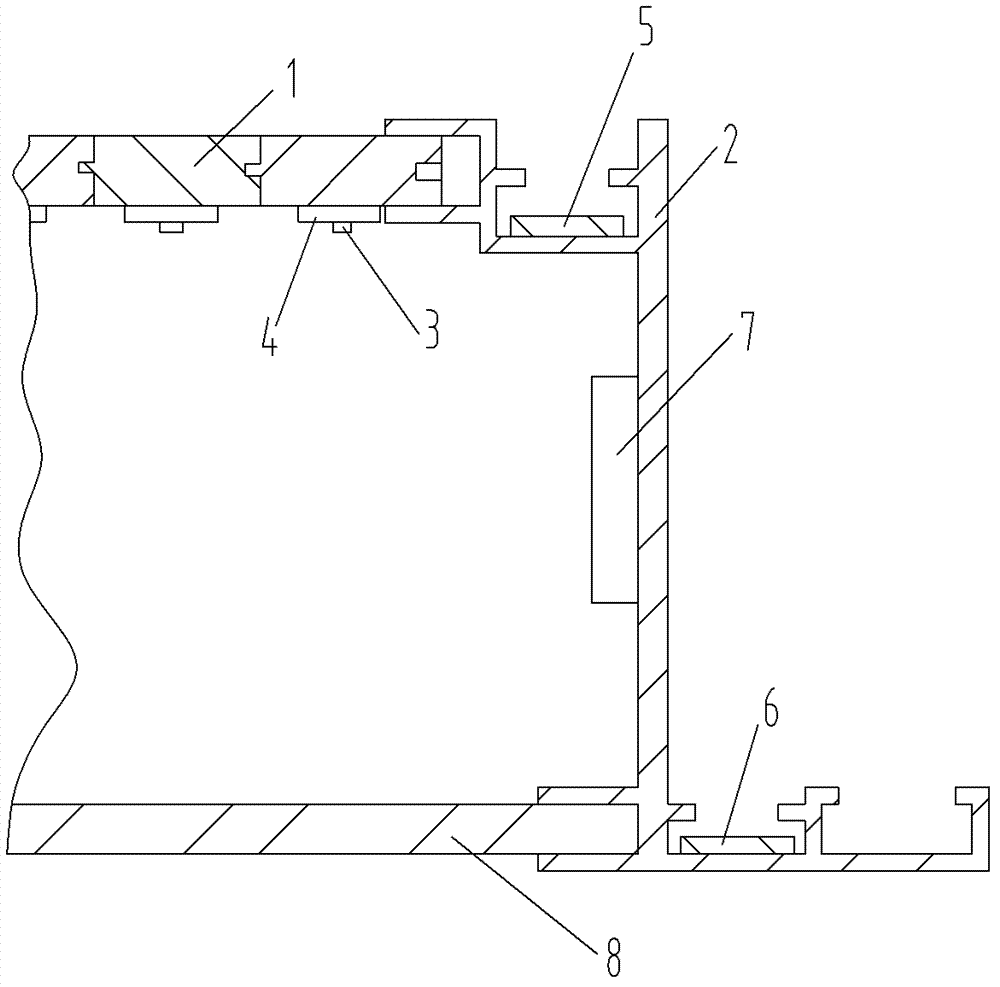

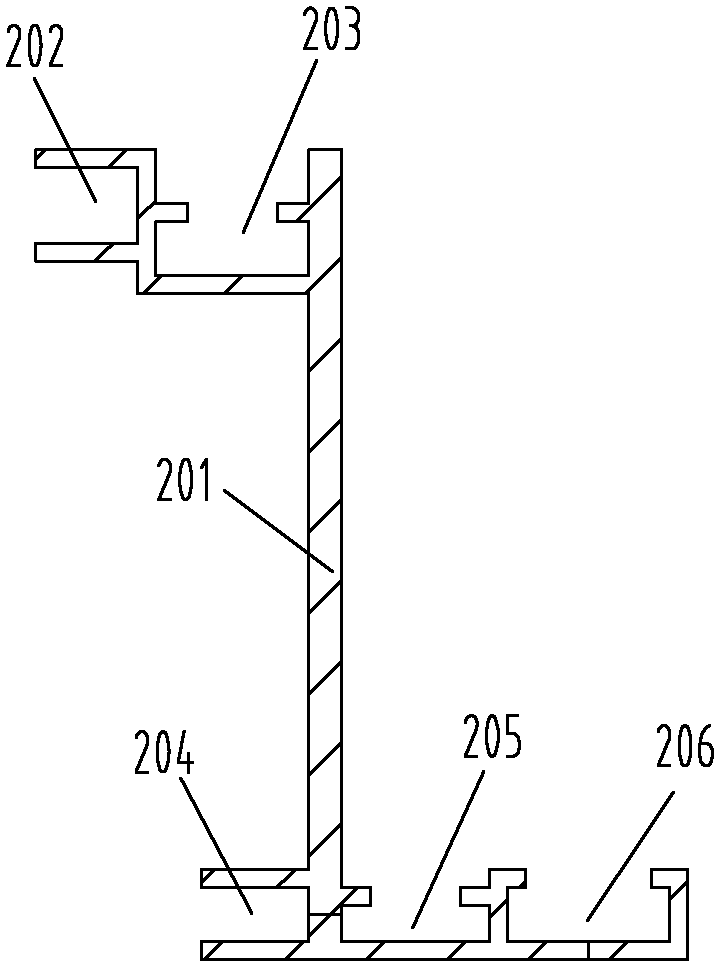

[0018] refer to figure 1 , is a back-emitting LED panel light source with a modular structure of the present invention, mainly including a frame 2 , a heat dissipation bottom plate 1 and a light diffusion plate 8 . The lower side of the frame 2 is engaged with the light diffusion plate 8 , and the upper side of the frame 2 is engaged with the heat dissipation bottom plate 1 , on which the heat dissipation bottom plate 1 is fixed with an aluminum substrate 4 , and a plurality of LED light source chips 3 are surface-mounted longitudinally on the aluminum substrate 4 . The power of the LED light source chip 3 is selected from 0.06W to 0.5W. The number of longitudinal surface-mounted LED light source cores 3 on the aluminum substrate 4 can be determined according to the light distribution design. The power module 7 is fixed inside the frame 2 .

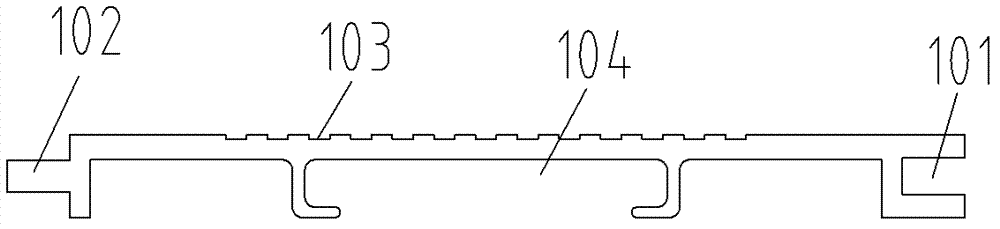

[0019] refer to figure 2 , the heat dissipation bottom plate 1 is formed by splicing a plurality of clamped aluminum-shaped plates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com