Electroluminescence device

An electroluminescent device and light-emitting area technology, applied in electroluminescent light sources, electric light sources, lighting devices, etc., can solve problems such as examples that have not reported success

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Best Mode for Carrying Out the Invention

[0034] Embodiments of the present invention will now be described with reference to the accompanying drawings.

[0035]

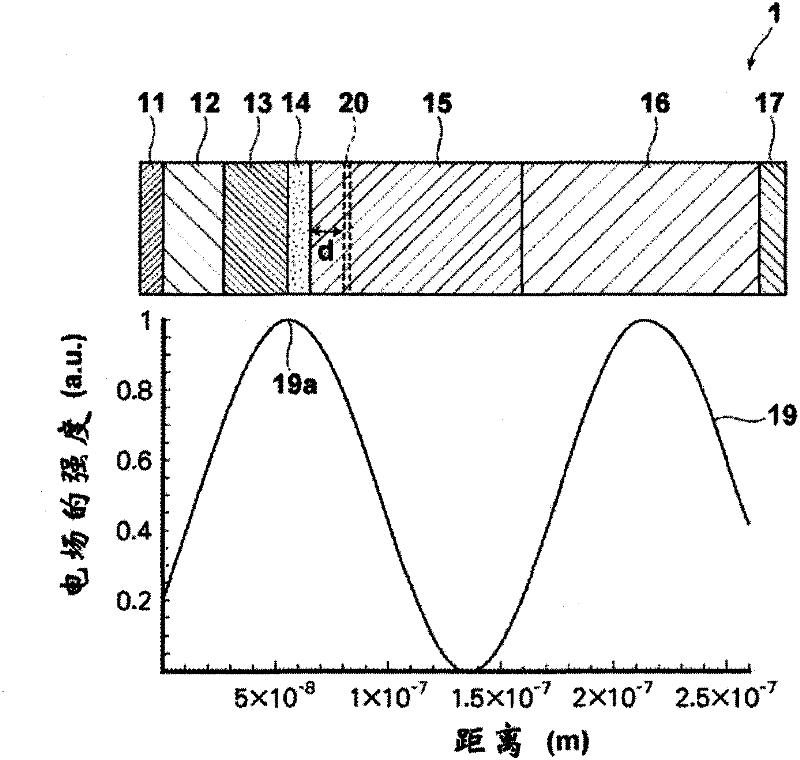

[0036] figure 1 is a schematic diagram illustrating the structure of the electroluminescence device (EL device) 1 according to the present embodiment. The EL device of the present embodiment is an organic EL device including a plurality of layers, and each layer thereof is formed of an organic layer.

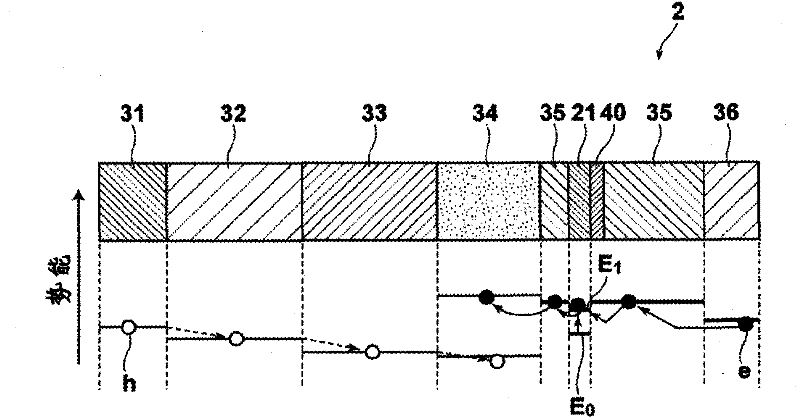

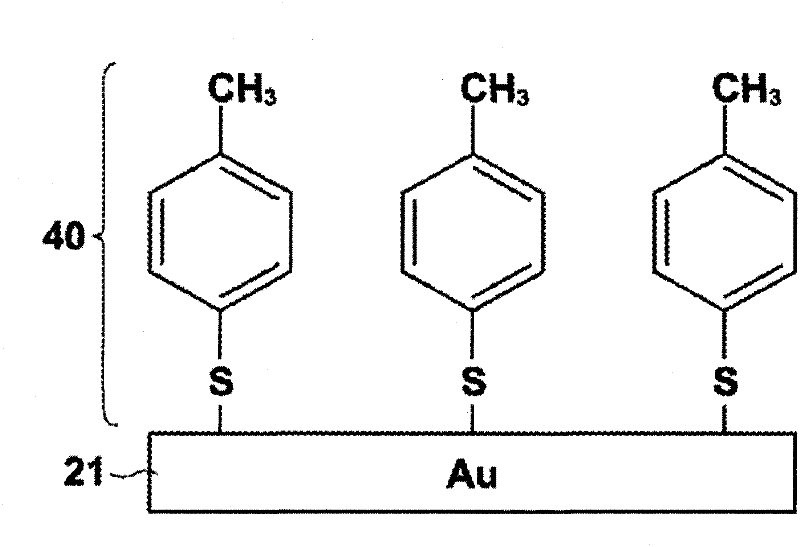

[0037] The organic EL device 1 of the present invention has the structure of a common EL device, mainly comprising a cathode 11, an electron injection layer 12, an electron transport layer 13, a light emitting layer 14, a positive hole transport layer 15, a positive hole injection layer 16 and an anode 17. The light-emitting layer 14 is Alq3 in this example. When electrons and positive holes (holes) respectively injected from the cathode 11 and the anode 17 combine with each other at the region (light emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com