Cold-rolled steel strip shape control method for actively preventing saturation phenomenon of executer

A control method and strip shape technology, which is applied in the field of cold-rolled strip steel, can solve problems such as the deterioration of the strip shape control effect, avoid actuator saturation, reduce the probability of actuator saturation, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

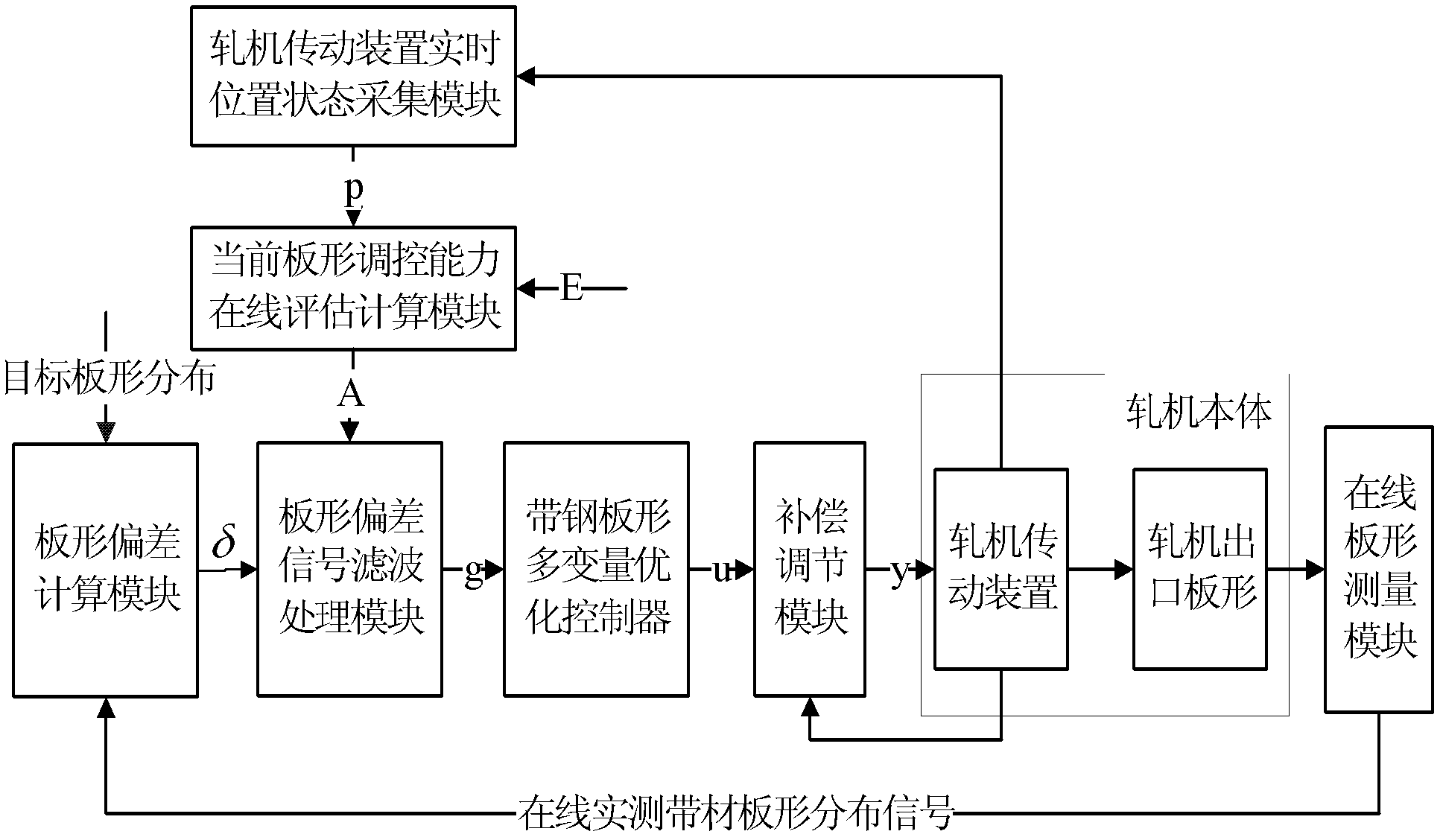

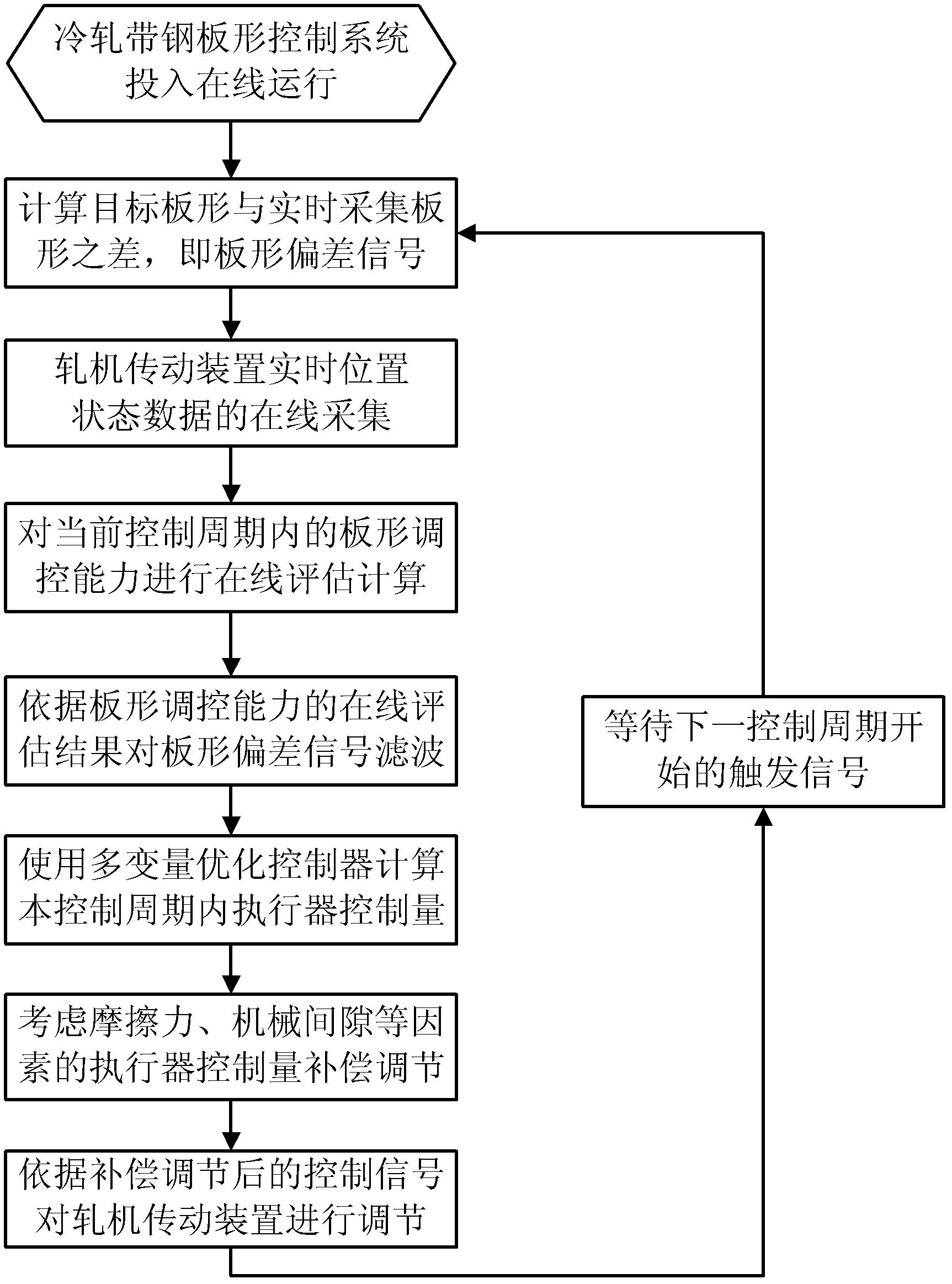

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

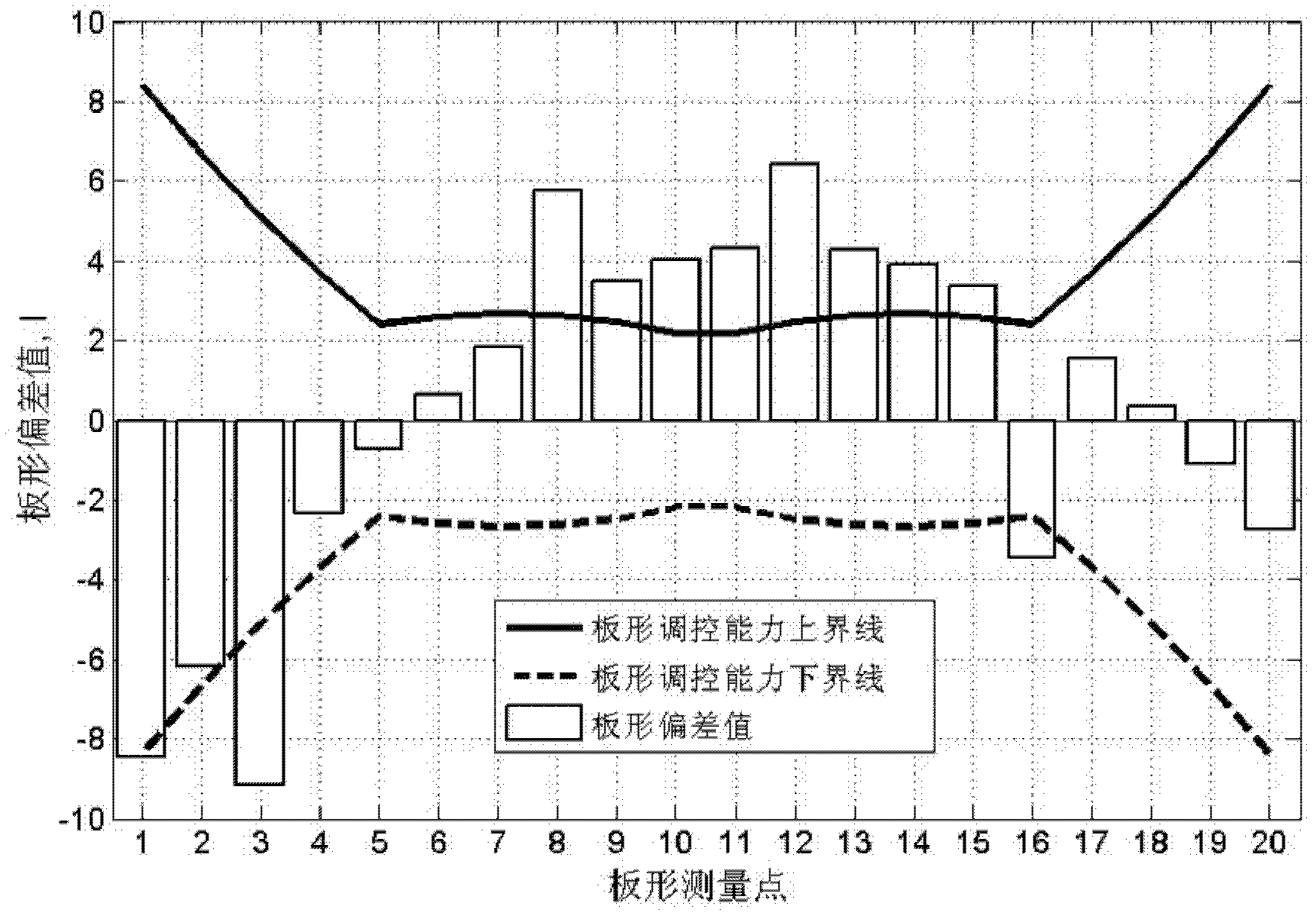

[0043] This embodiment discloses a flatness control method for actively avoiding actuator saturation in a six-high cold rolling mill with horizontally movable work rolls. The product specification of this example (thickness × width): 0.35mm × 1250mm, steel type: high-grade non-oriented HNGO, rolling speed: maximum 900m / min, coiling tension 220KN, main motor power 5500KW, intermediate roll lateral movement - 200-200mm, the bending force of the work roll is -540KN-540KN, the bending force of the middle roll is 0-360KN. The automation level is used for the transmission and exchange of process control data. The flatness measurement device uses the Stressometer flatness roll of ABB Company in Sweden. The flatness roll has a diameter of 313mm and is composed of a solid steel shaft. The measurement area, in which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com