Granular material multilayer calcining furnace and calcining method

A granular material and calcination furnace technology, which is applied in the field of calcination furnace, can solve the problems of calcination of granular materials, and achieve the effect of not easy to agglomerate, easy to flow, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention is described in conjunction with accompanying drawing and given embodiment, but does not form any restriction to the present invention:

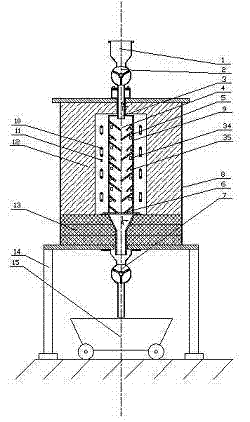

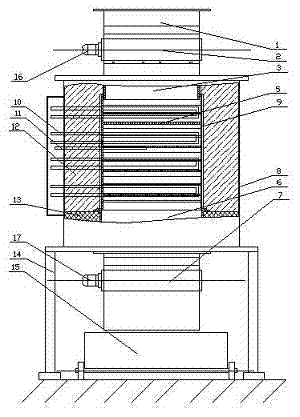

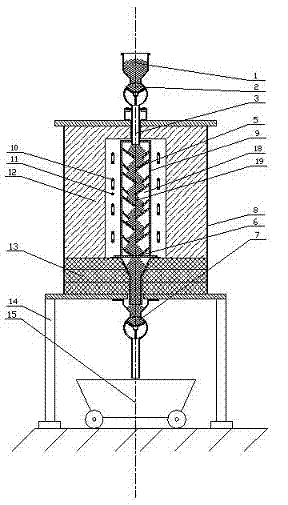

[0038] Such as figure 1 , figure 2 shown, and refer to image 3 , a multi-layer calciner for granular materials, mainly including a furnace body, a feed part, a discharge part, a heating part and a control system; the furnace body is vertical, and the furnace body is composed of a furnace shell 8, a furnace lining 12 Composition; the feed part located at the upper part of the furnace body mainly includes a feed bin 1, a feeder 2 and a feed port 3; the feeder 2 can adopt a rotary feeder, a screw feeder, a push Rod conveyor etc., feeder 2 adopts rotary feeder in this embodiment. There is a calcination cabin in the hearth of the furnace body. In this embodiment, the calcination cabin bulkhead 9 is a square cylinder structure, which can avoid the contact between the material and the furnace lining, so that the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com