Base paper for paper container and laminate sheet for paper container using same

A technology for laminating sheets and paper containers, which is applied in the field of paper boards, can solve problems such as strength reduction, and achieve the effects of inhibiting damage, excellent processing suitability, and high printing suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] (Paper material slurry A for the outer layer)

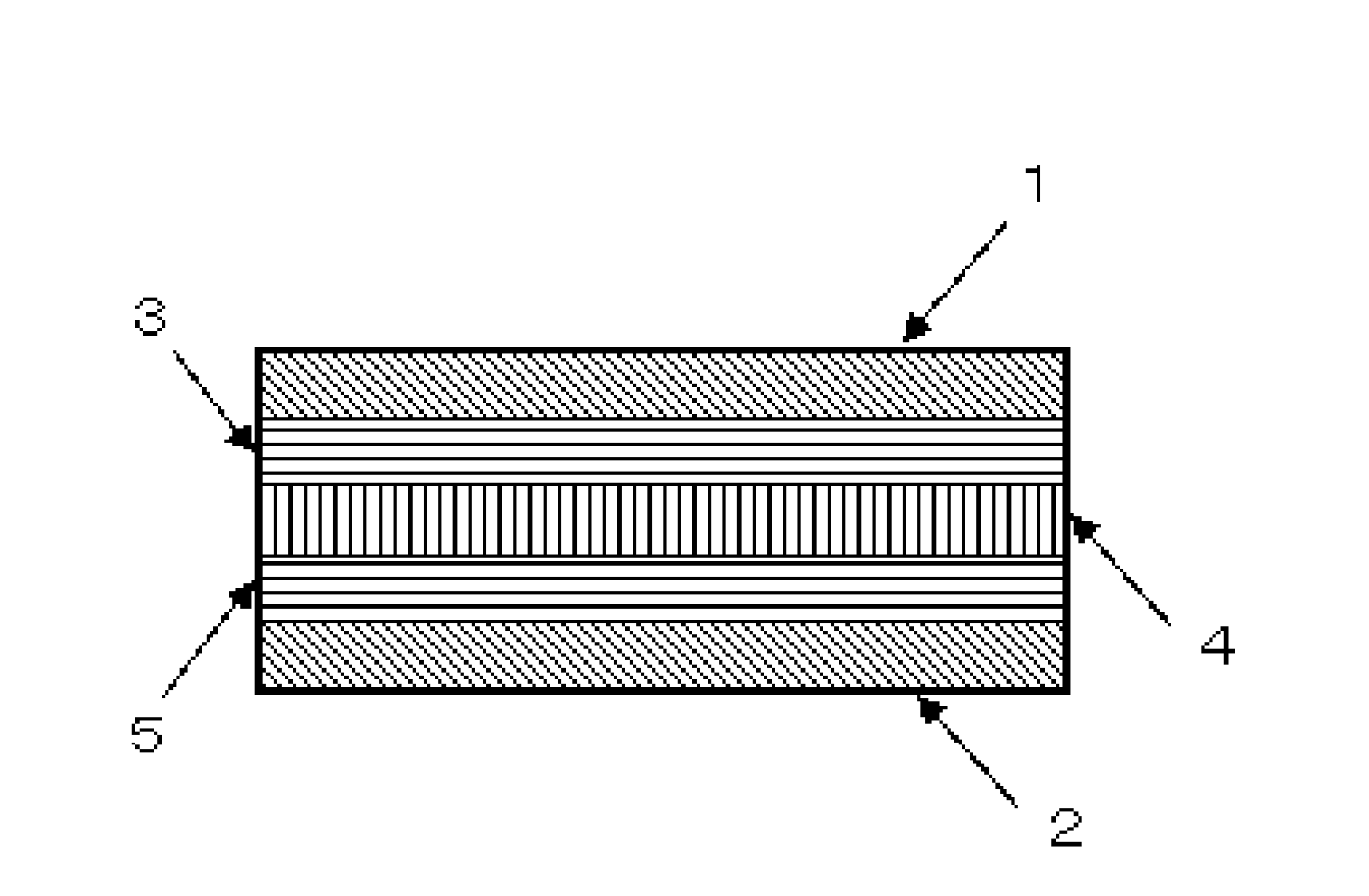

[0109]Coniferous bleached kraft pulp (NBKP) with a Canadian Standard Freeness (CSF) of 500ml and hardwood bleached kraft pulp (LBKP) with a CSF of 450ml were blended at a mass ratio of 40 / 60 as raw material pulp. In the raw material pulp slurry, 0.3 parts by mass of polyacrylamide with a molecular weight of 2.5 million as a dry paper strength enhancer is added relative to 100 parts by mass of the total raw material pulp (absolutely dry pulp mass), and alkane as a sizing agent in the pulp Add 0.5 parts by mass of base ketene dimer relative to 100 parts by mass of total raw material pulp (absolutely dry pulp mass), and add polyamide epichlorohydrin resin as a wet paper strength reinforcing agent relative to 100 parts by mass of total raw material pulp ( dry pulp mass) after adding 0.1 parts by mass, adjust the pH to 7.5 with sodium hydroxide, and use it as paper stock slurry A for the outer layer.

[0110] (Paper material s...

Embodiment 2

[0114] In addition to mixing NBKP and LBKP at a mass ratio of 50 / 50, the outer layer 1 and outer layer 2 use the outer layer paper slurry A1 made in the same way as the outer layer paper slurry A, with a grammage of 79g / m 2 Preparation, except that the inner layer 1 uses paper material slurry a for the inner layer, with a gram weight of 159g / m 2 Except preparation, same as embodiment 1, obtain grammage 320g / m 2 , Density 0.75g / cm 3 paper container base paper.

Embodiment 3

[0116] In addition to adding 0.3 parts by mass of the alkyl ketene dimer as the pulp internal sizing agent relative to 100 parts by mass of the total raw material pulp (absolute dry pulp mass), adding aluminum sulfate to 100 mass parts of the total raw material pulp (absolute dry pulp mass) mass) except adding 0.08 parts by mass, the outer layer 1 and the outer layer 2 use the outer layer paper slurry A2 made in the same way as the outer layer paper slurry A1, with a grammage of 79g / m 2 Preparation, in addition to adding 0.3 mass parts of the alkyl ketene dimer as the pulp internal sizing agent relative to the total raw material pulp 100 mass parts (absolute dry pulp quality), adding aluminum sulfate relative to the total raw material pulp 100 mass parts (absolute dry pulp quality) dry pulp mass) addition of 0.08 parts by mass, the inner layer 1 uses the same inner layer paper stock slurry a1 made as the inner layer paper stock slurry a, with a grammage of 159g / m 2 Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com