Method and device for carrying out uniform heating or differential heating on sheet steel in rapid non-deformation non-oxidation mode

A technology of uniform heating and differential temperature heating, applied in heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve the problems of inability to accurately control differential temperature heating of thin steel plates, deformation of thin steel plates, and increased investment costs of heating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

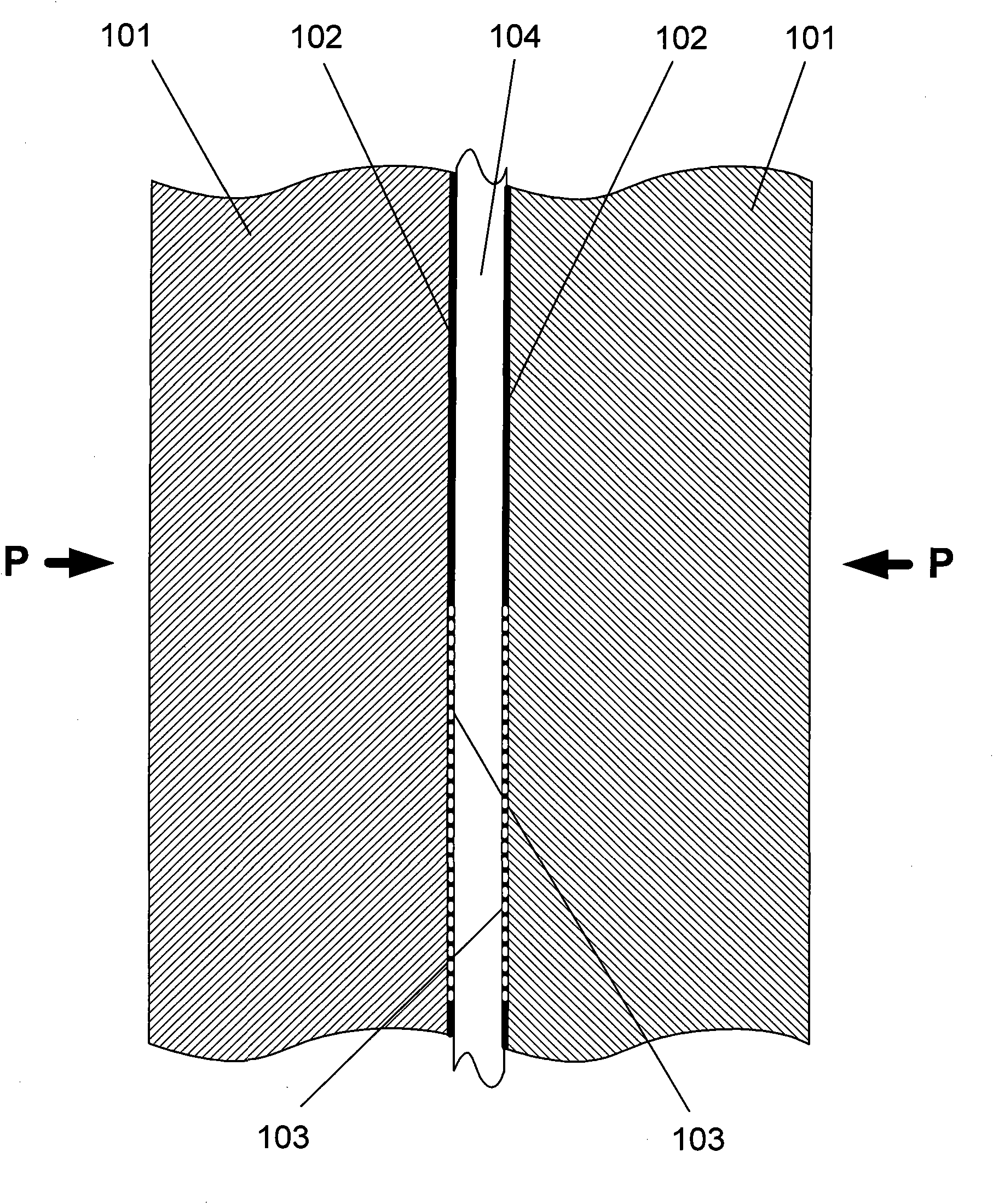

[0014] figure 1 It is a schematic diagram of the thin steel plate contact heating method. A pair of heating templates 101 made of heat-resistant steel placed in an isothermal heating device will clamp the heated steel plate 104 under the action of clamping force P. Compared with the heated steel plate 104, the heating template 101 has sufficient thickness and heat capacity, so its temperature fluctuation during the heating process can be ignored. The heating template 101 has a composite heat exchange surface composed of a high heat exchange area 102 and a low heat exchange area 103, and the heat exchange coefficient between the former and the steel plate to be heated is obviously higher than the latter. Therefore, the part of the heated steel plate 104 in contact with the high heat exchange zone 102 can be rapidly heated to the temperature close to the temperature of the heating template 101 itself, while at the same time, the part in contact with the low heat exchange zone 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com