LED (Light-Emitting Diode) encapsulated lens

An LED packaging and lens technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of LED luminous brightness loss and inability to reduce light source loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

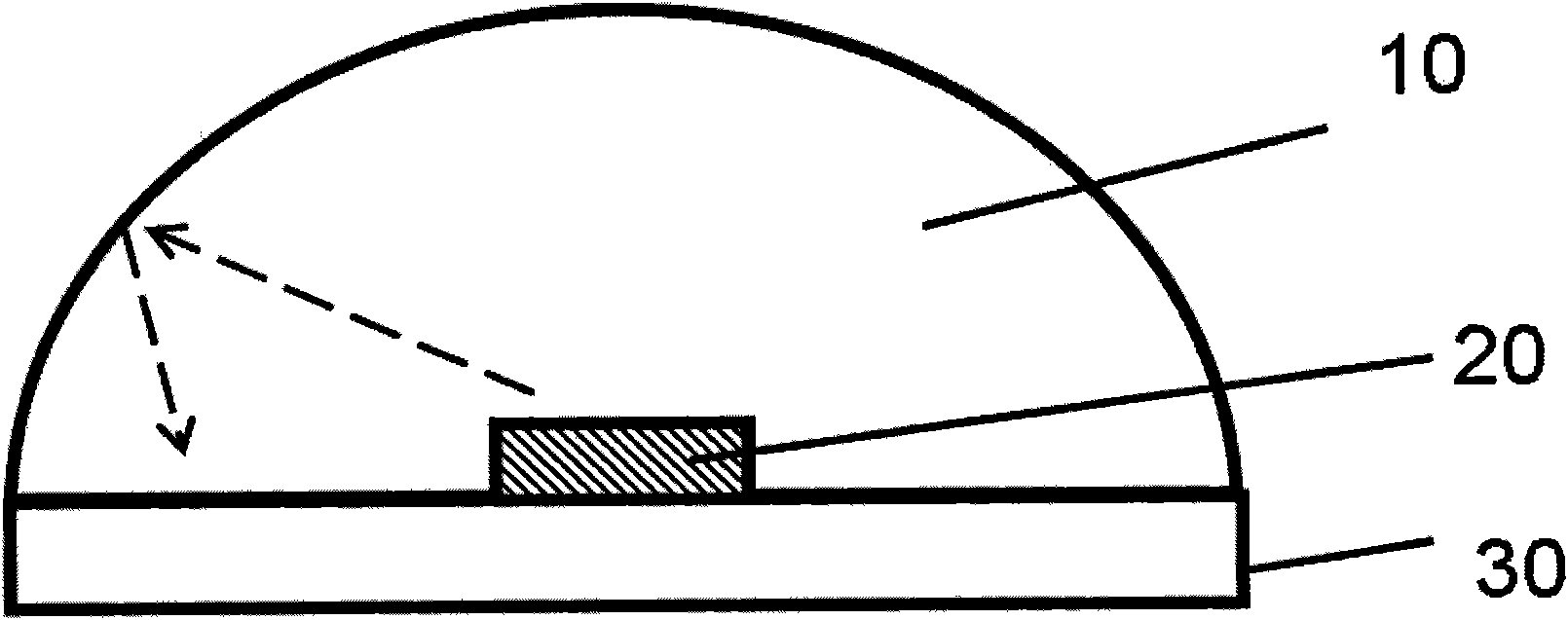

[0025] In order to more clearly describe the features of the LED packaging lens proposed by the present invention, the following will be described in detail with reference to the drawings. In the present invention, an LED encapsulation lens is taken as an embodiment, which is described in detail with reference to the drawings.

[0026] The LED upstream epitaxial wafer is cut into a chip, and then the chip is pasted on the lead frame and enters the downstream LED packaging process. According to the application of different LED products, there are different LED chip packaging technologies and materials.

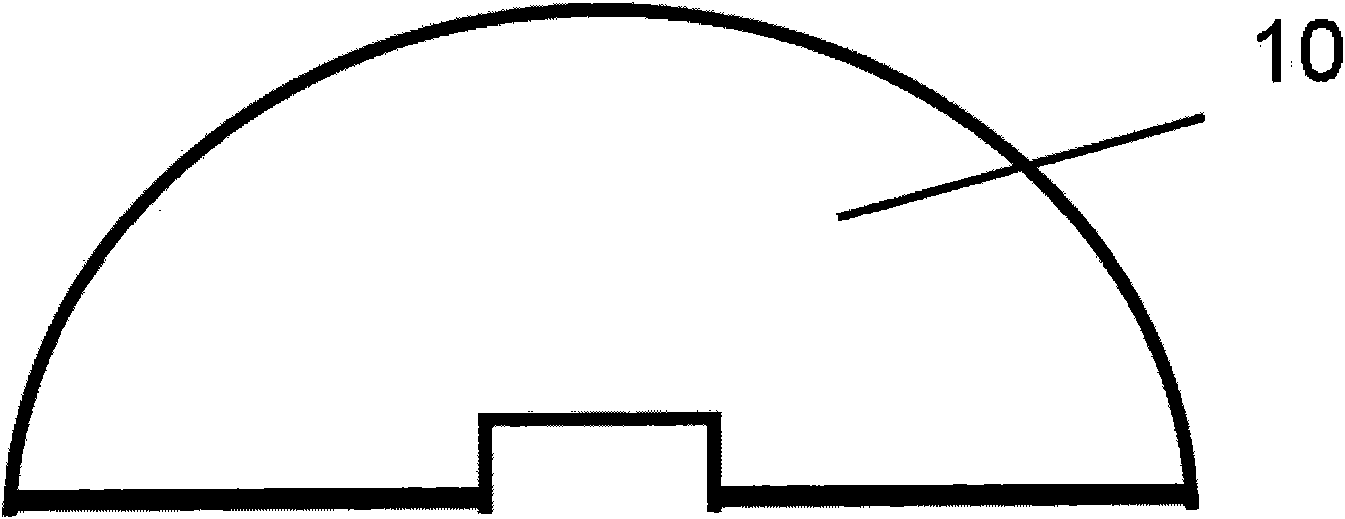

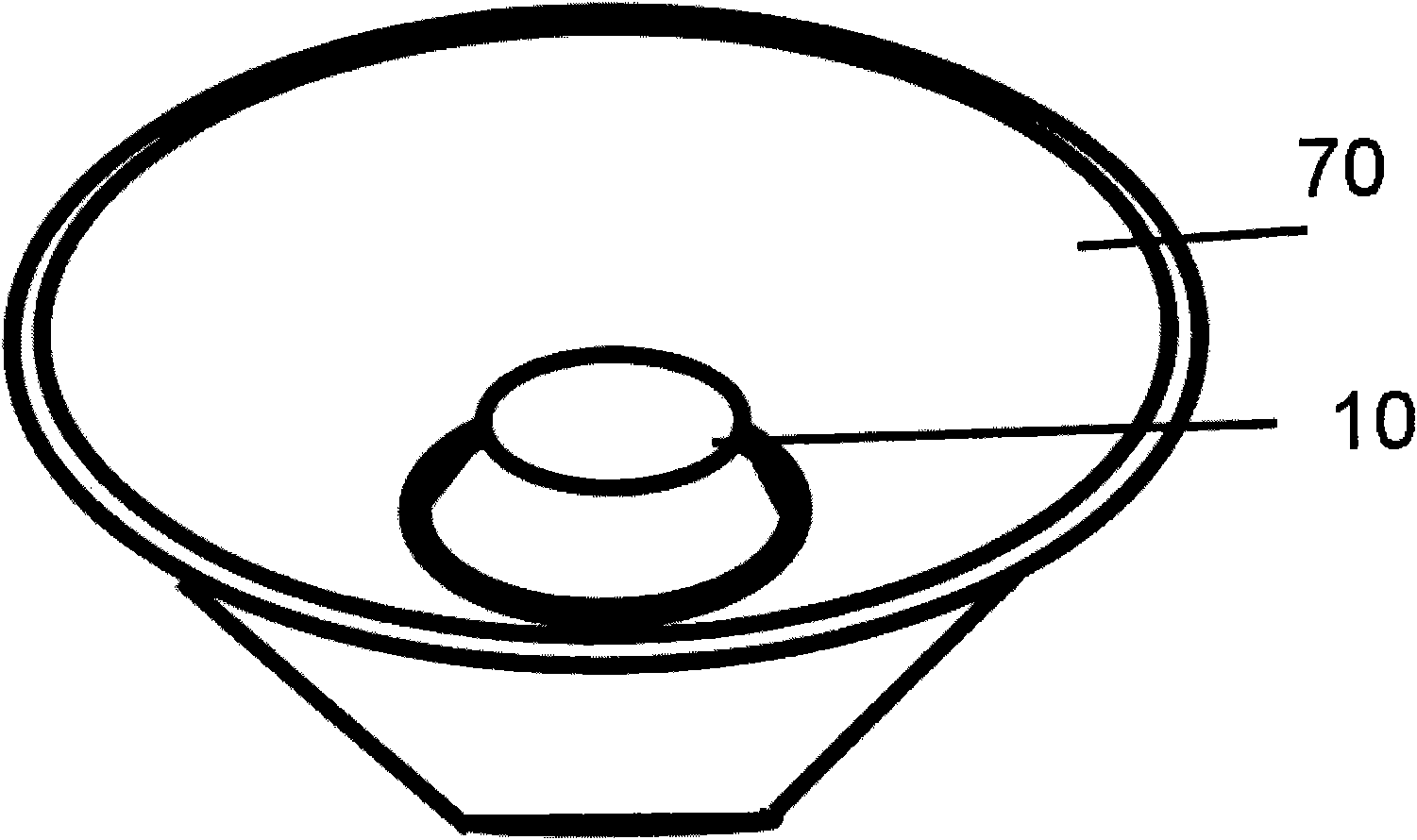

[0027] Generally speaking, the LED packaging lens is a plano-convex lens 10 , which is in the shape of a hemisphere, a dome, a semi-ellipse or a frustum of a dome (such as a truncated dome). The lens material can be glass, quartz or plastic. Among them, common plastic lens materials are: epoxy resin (epoxy), polycarbonate (PC), silicone (silicone) and the like.

[0028] fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com