Optical fiber plasma discharge laser amplification device and technology

A technology of micro-plasma and laser amplification, which is applied in the direction of lasers, phonon exciters, laser components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

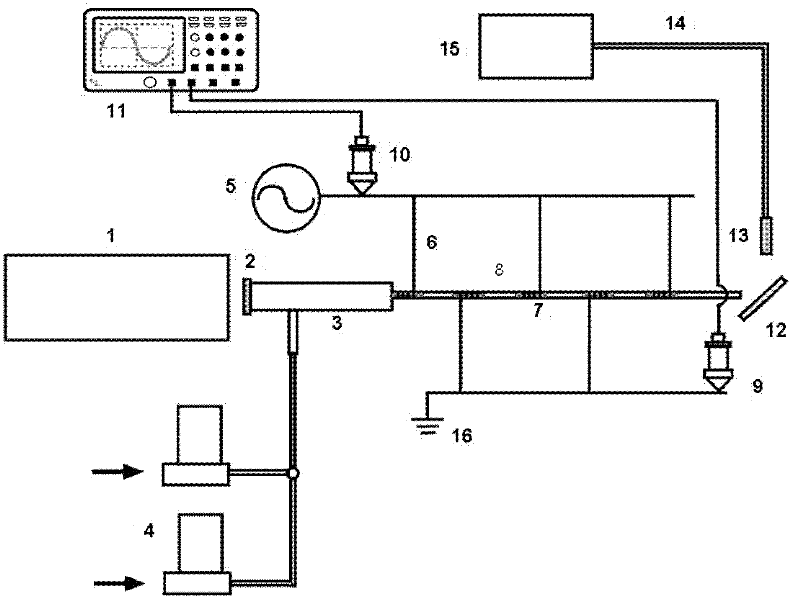

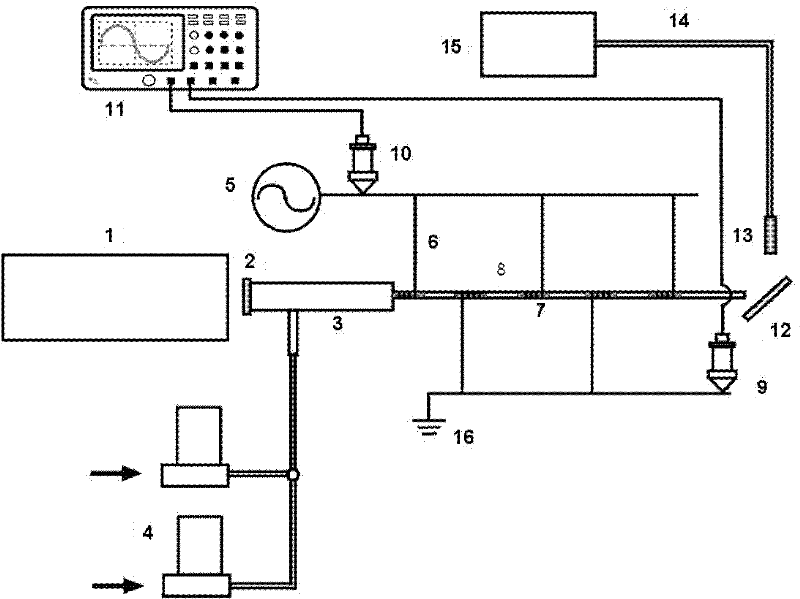

[0023] A kind of optical fiber micro-plasma discharge laser amplifying device, such as figure 1 As shown, the length of the optical fiber 8 for discharge is 150mm, and the outer wall of the optical fiber is wrapped with a copper ring 7 with a width of 10mm every 10mm, and the high voltage power supply 5 is alternately connected with a thin copper wire 6 (sinusoidal AC power supply, voltage adjustable range 0-20kV, Frequency adjustable range 0-20kHz) and ground wire 16. The ratio of the reaction gas is adjusted by the mass flow controller 4 and fully mixed in the quartz tube 3 at the rear end of the optical fiber. When the applied voltage peak-to-peak value is 4kV-9kV and the frequency is lower than 15kHz, a uniform and stable micro-plasma is generated. The helium-neon laser 1 emits a laser beam through the smooth quartz plate 2 at the end of the quartz tube and pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com