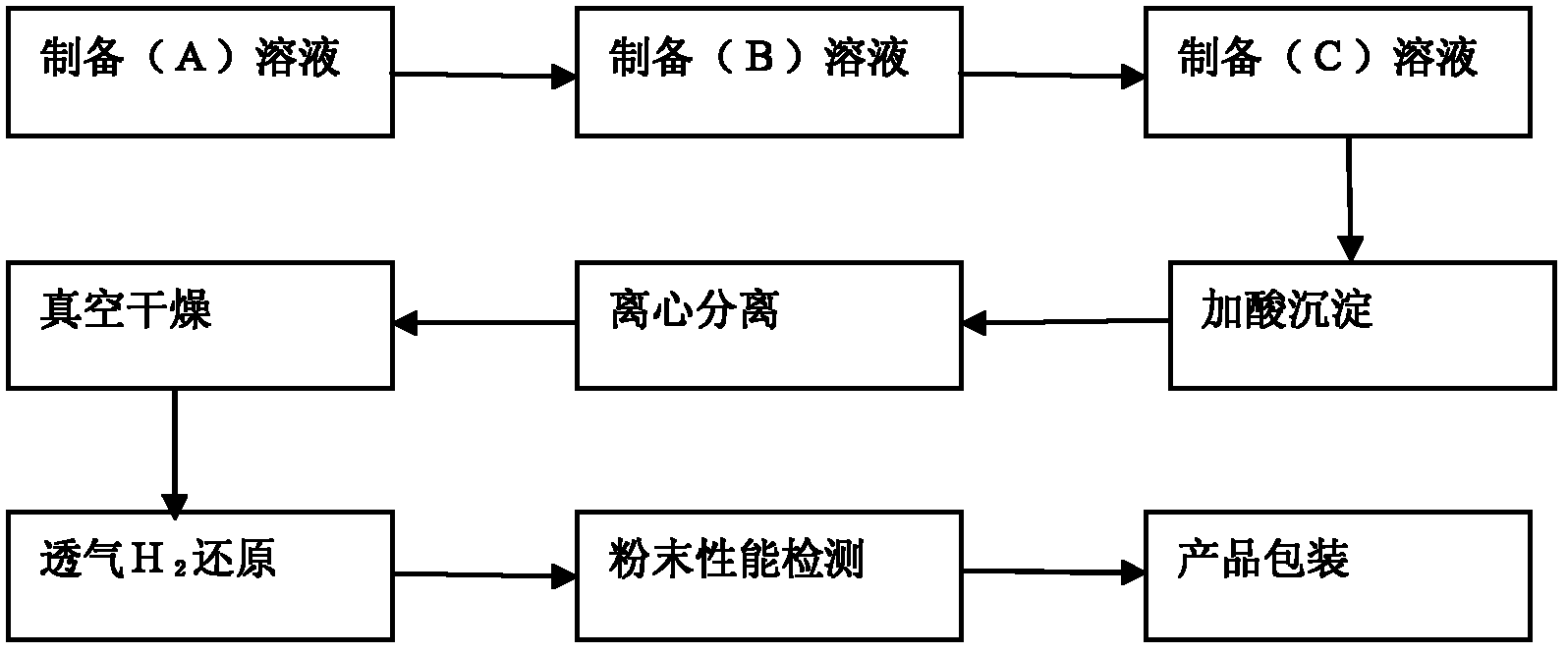

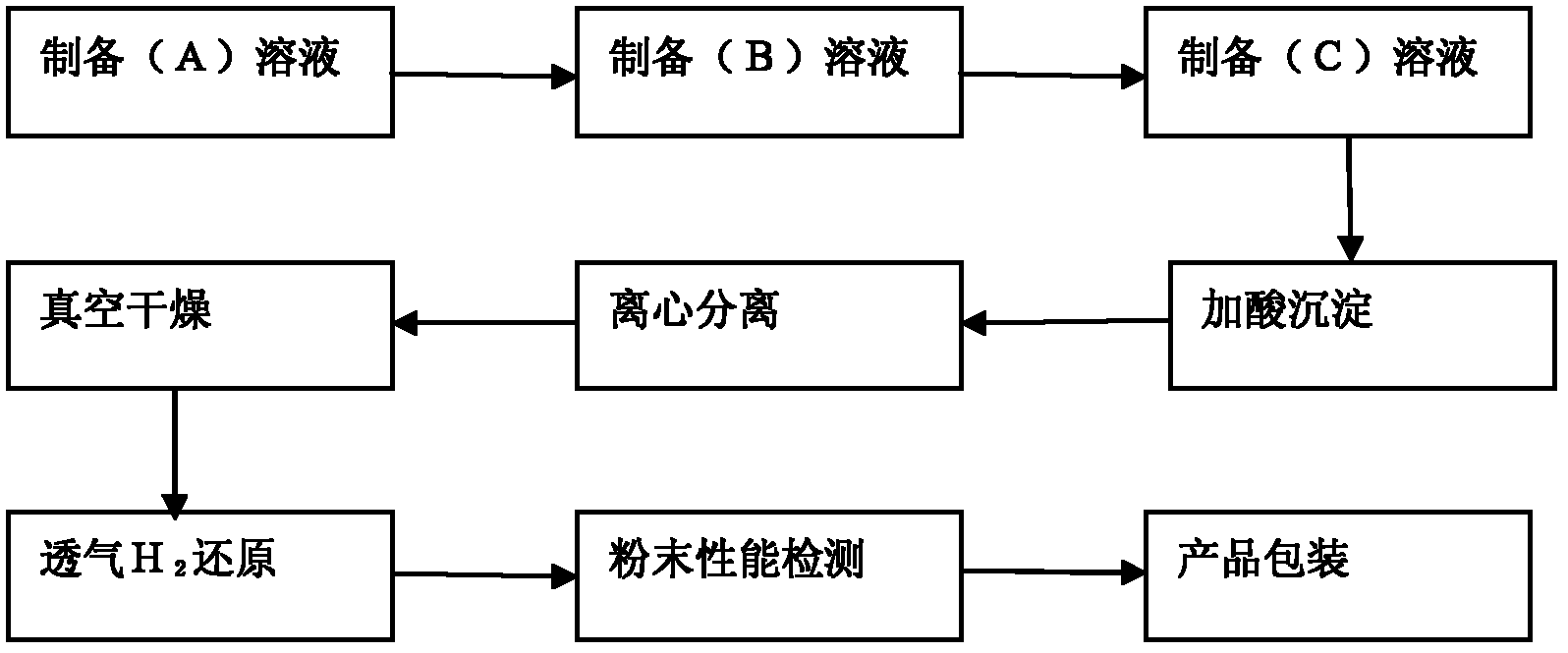

Method for preparing nano-tungsten powder by using sulfuric acid precipitation-H2 breathable reduction process

A nano-tungsten powder, -H2 technology, applied in the field of metal powder preparation, can solve the problems of inability to produce nano-scale tungsten powder, tungsten powder, ammonium tungstate or tungsten trioxide coarse particles, etc., so as to improve the production efficiency of precipitation , Improve the level of automated production, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: To prepare 1kg of nano-tungsten powder should be completed according to the following steps.

[0036] 1. Prepare A solution: weigh 30% (containing WO 3 mass fraction) of ammonium tungstate solution 4204g, add 6680g of distilled water, and stir continuously to make 10.88kg of dilute ammonium tungstate solution (A) with a concentration of 0.5mol / L.

[0037] 2. Prepare solution B: Weigh 21.8g each of PVA powder and SDS powder and add to 1047g of distilled water at the same time to make 1090.6g of isolation-dispersant solution (B) with a concentration of 4% (mass).

[0038] 3. Preparation of solution C: mix A and B solutions according to A:B=10:1 (volume ratio), mix 10.88 kg of A solution with 1.09 kg of B solution, and prepare a solution containing isolation-dispersant (0.336% by mass) Concentration) solution (C) 11.99kg.

[0039] 4. Precipitation by adding acid: prepare dilute sulfuric acid solution: slowly add concentrated sulfuric acid into distilled water ...

Embodiment 2

[0049] Example 2: The preparation of 5kg nano-tungsten powder should be completed according to the following steps.

[0050] 1. Prepare A solution: weigh 30% (containing WO 3 mass fraction) of ammonium tungstate solution 21020g, add distilled water 33400g, stir continuously to make 54.42kg dilute ammonium tungstate solution (A) with a concentration of 0.5mol / L.

[0051] 2. Prepare solution B: Weigh 109g of PVA powder and SDS powder and add to 5235g of distilled water at the same time to make 5344g of isolation-dispersant solution (B) with a concentration of 4% (mass).

[0052] 3. Prepare C solution: mix A and B solutions according to A:B=10:1 (volume ratio), mix 54.40 kg of A solution with 1.09 kg of B solution, and prepare a solution containing isolation-dispersant (0.336% by mass). Concentration) solution (C) 59.95kg.

[0053] 4. Precipitation by adding acid: prepare dilute sulfuric acid solution: slowly add concentrated sulfuric acid into distilled water to prepare 59.95k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com