Human-powered railcar

A human-driven, rail car technology, applied to motor vehicles, bicycles, transport buses, etc., can solve the problems of bicycle speed and high-speed maintenance performance, limited physical strength of drivers, and increased frictional resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

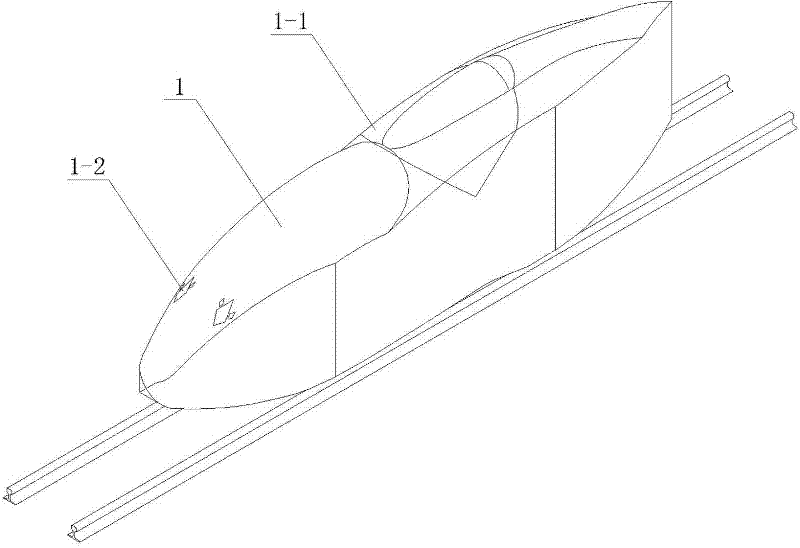

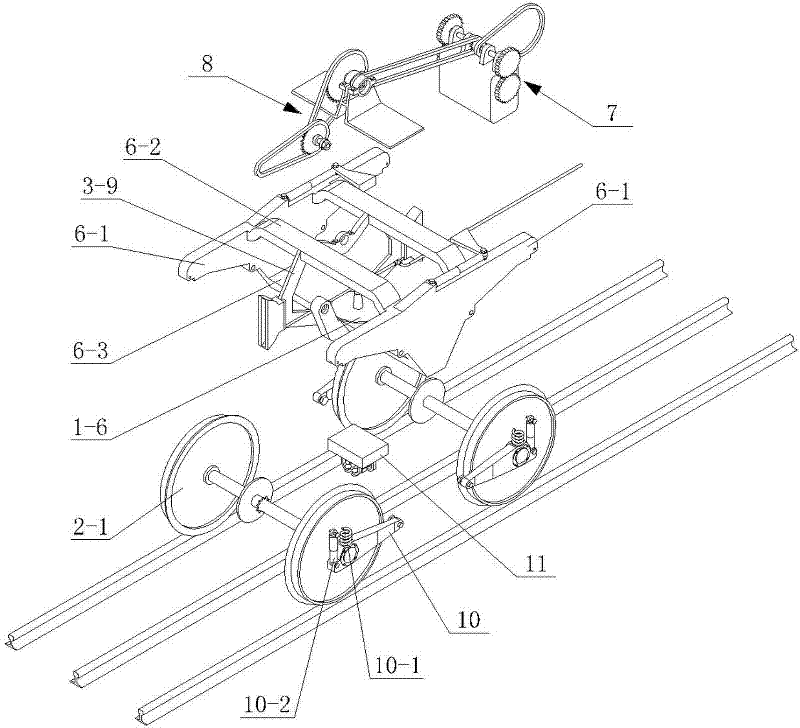

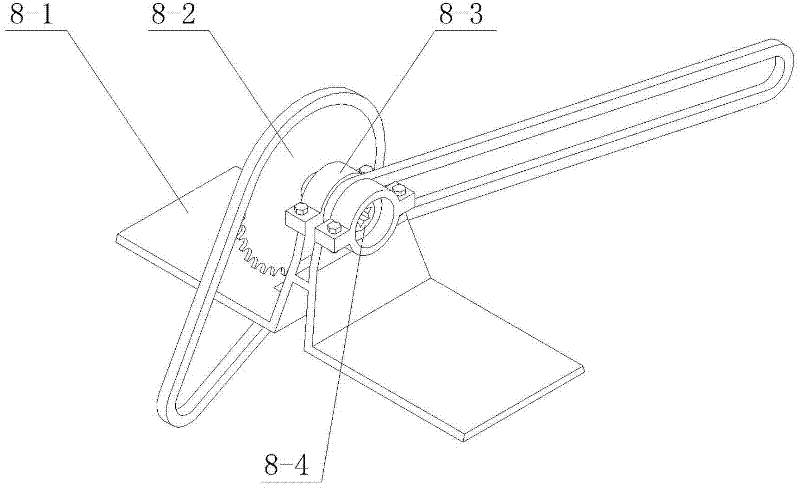

[0075] Such as figure 1 , figure 2 , image 3 Shown is one of the designed embodiments of the present invention. In this embodiment, a human-powered railcar is composed of a driving wheel pair and a driven wheel pair. The driving wheel pair and the driven wheel pair respectively include a pair of The track is matched with wheels 2-1, and the track used in this embodiment is composed of two light rails.

[0076] Such as figure 1 , figure 2 As shown, the wheels 2-1 of each set of wheel sets are axially mounted with a wheel axle 2-2 in the central part, and a fairing 1 covering the traveling system is provided through the journal of the wheel axle 2-2. The fairing 1 is It is streamlined and has a bottom plate to form the body of the rail car. The fairing 1 is made of light materials, such as carbon fiber or engineering plastics, which has sufficient mechanical strength and light weight. The whole body is a shell, and it can cooperate with the driver. The upper part of the housing ...

Embodiment 2

[0086] Figure 4 , Figure 5 , Image 6 Shown is the second embodiment of the present invention. The difference from Embodiment 1 is that in this embodiment, the rail car is driven by two persons, and two seats 4 are installed inside the carriage to cooperate with two drivers. The seats 4 are arranged in a single row along the forward direction of the rail car. The first seat 4 has a backrest 4-1, and the backrest 4-1 is installed with a drive train bracket 4 in a position between the second adjacent seat. -2. A second driving sprocket for adjacent drivers is installed on the drive train bracket 4-2. The driving sprocket is connected and combined with the previous driving sprocket through the transmission chain, and the second driver passes The driving sprocket provides driving force and transmits the driving force to the previous driving sprocket. The driving forces of the two drivers are combined and transmitted to the driving sprocket of the drive train.

[0087] Such as Figu...

Embodiment 3

[0092] Figure 7 , Figure 8 , Picture 9 , Picture 10 , Figure 16 Shown is the third embodiment of the present invention. In this embodiment, a human-powered railcar is composed of a front bogie and a rear bogie to form a walking system. The fairing 1 of the carriage, the front bogie and the lower part of the rear bogie are equipped with closed covers 1-7; the fairing 1 is equipped with a human-powered walking system through the bottom plate and a drive system that moves forward along the track, and is installed to control the walking state of the rail car In conjunction with the drive system, a drive train that transmits the driving force of the driver is installed on the bottom plate of the fairing, and a number of driver seats 4 that are matched with the drive system, control system and drive train are installed.

[0093] The rail used in this embodiment is composed of three light rails, and the middle rail is an auxiliary rail for safety protection.

[0094] Such as Figure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap