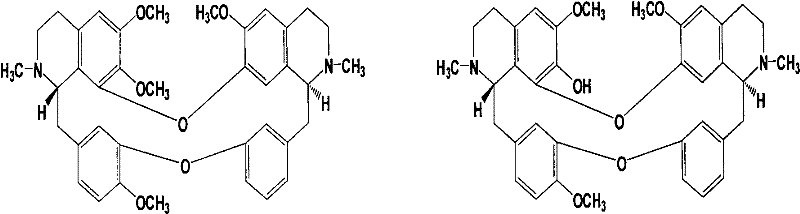

Extraction method of tetrandrine and demethyltetrandrine

A technology of fenacetin A and fenacetin B, applied in the field of separation and extraction of plant active components, can solve the problems that carriers are not suitable for recycling, the process is not easy to enlarge, and the production cost is high, so as to reduce the potential of the environment and operators. Harm, improve the utilization rate of raw materials, the effect of small loss of target components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Step 1. Extract the extract: crush the Hanfangji medicinal material into 20-mesh coarse powder, take 100kg, add 2kg of quicklime powder and mix evenly, put it into a stainless steel multifunctional extraction tank, add 400kg of methanol solution with a volume concentration of 70% , heated and kept boiling for 2 hours, filtered out the solution; then extracted twice with 300kg of 70% methanol solution according to the above method, combined three times of the gained extract, concentrated under reduced pressure and reclaimed methanol, to obtain a total alkaloid extract with a specific gravity of 1.12;

[0019] Step 2, extraction for the first time: the hydrochloric acid aqueous solution of gained extract is dissolved at 35 ℃ with the hydrochloric acid aqueous solution of 5% concentration, makes it become the acidic aqueous solution that pH is 2, with ethyl acetate and chloroform (volume ratio 1: 5) The mixed solvent is used as the extraction solvent to extract the tetrand...

example 2

[0023] Step 1. Extraction extract: crush 200kg of Hanfangji medicinal material into 40-mesh coarse powder, add 5kg of quicklime powder and mix evenly, put it into a stainless steel multifunctional extraction tank, add 800kg of ethanol solution with a volume concentration of 80%, and heat Keep boiling for 2 hours, filter out the solution; then use 600kg of 80% ethanol solution to extract twice according to the above method, combine the extracted solution obtained three times, concentrate under reduced pressure and recover ethanol, and obtain a total alkaloid extract with a specific gravity of 1.15;

[0024] Step 2, the first extraction: dissolve the extract obtained in step 1 with 2% sulfuric acid aqueous solution at 35°C to make it an acidic aqueous solution with a pH of 2.5, and use chloroform as the extraction solvent to extract the acidic aqueous solution Tetrandrine, at the same time detected by TLC, until there is no obvious tetrandrine reaction spots in the acidic aqueous...

example 3

[0028] Step 1. Extract the extract: add 500 kg of 50-mesh Chinese Fangji medicinal material coarse powder, add 15 kg of quicklime powder and mix evenly, put it into a stainless steel multifunctional extraction tank, add 2000 kg of ethanol solution with a volume concentration of 85%, and heat to keep boiling 2 hours, filter out solution; Then extract twice with the 85% ethanol solution of 1500kg respectively according to the above-mentioned method, merge three times gained extracts, concentrating under reduced pressure reclaims ethanol, obtains the total alkaloid extract that specific gravity is 1.15;

[0029]Step 2, the first extraction: dissolve the extract obtained in step 1 with a 2% phosphoric acid aqueous solution at 60°C to make it an acidic aqueous solution with a pH of 2.5, and use chloroform as the extraction solvent to extract Han in the acidic aqueous solution. Tetrandrine is detected by TLC method at the same time until there is no obvious tetrandrine reaction spot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com