Defoaming agent used for molasses alcohol fermentation

A technology of molasses alcoholic fermentation and defoaming agent, which is applied in fermentation, biofuel, etc., can solve the problems of weak defoaming ability, weak long-term foam control ability, hazards, etc., and achieve good use effect and excellent defoaming and suppressing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] A method for preparing a defoamer for molasses alcoholic fermentation, comprising the following steps:

[0014] 1) Add 6-16 parts of polydimethylsiloxane, 6-10 parts of compound emulsifier, 4-12 parts of polyether, 4-12 parts of polyglycerin fatty acid ester into the beaker, and heat up to 85-95 °C;

[0015] 2) Add water and mix well.

[0016] In step 2), preferably, the ratio of the mass of added water to the sum of the mass of each material in step 1) is 1.8-2.8:1.

Embodiment 1

[0019] A kind of defoamer that is used for molasses alcoholic fermentation, its raw material composition is as follows:

[0020]

Embodiment 2

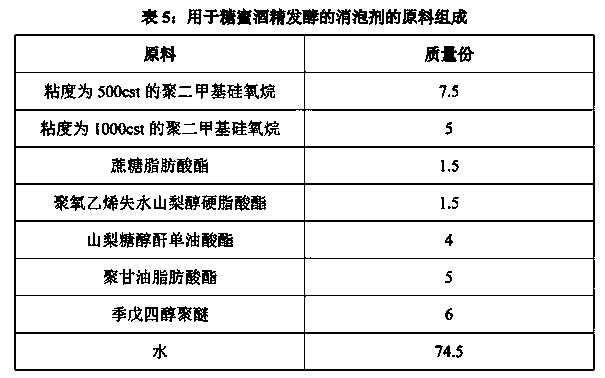

[0022] A kind of defoamer that is used for molasses alcoholic fermentation, its raw material composition is as follows:

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com