Molten iron smelting method and vanadium-containing molten iron smelting method

A smelting method and molten iron technology, applied in the direction of manufacturing converters, etc., can solve problems such as difficulty in slagging and dephosphorization of molten iron, and achieve the effects of low production cost, stable desulfurization, and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

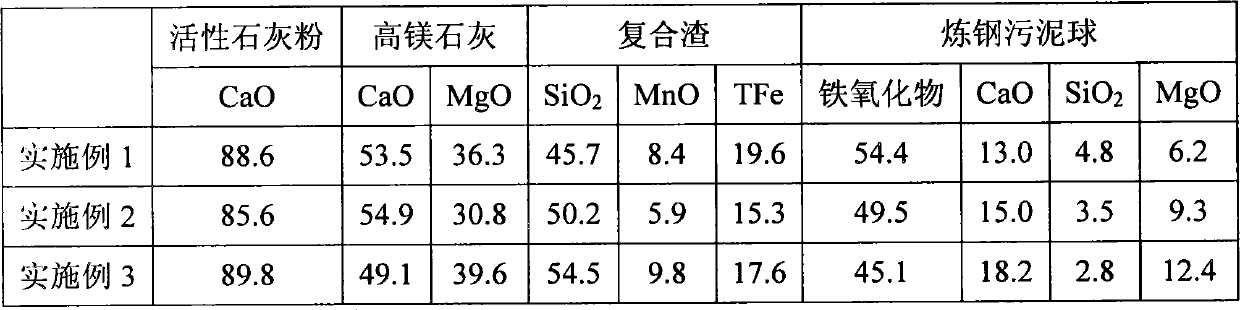

Embodiment 1

[0035] In this embodiment, 27CrMoV high-grade low-phosphorus-sulfur pipeline steel is smelted.

[0036] (1) Carry out compound injection deep desulfurization with vanadium-containing molten iron as raw material, its injection time is 18.33 minutes, with respect to 1 ton of vanadium-containing molten iron, use 3.53 kilograms of passivated lime powder (the content of CaO is 93.2% by weight), 0.91 kg of passivated magnesium powder (the metal Mg content is 93.4% by weight) to obtain desulfurized molten iron. In vanadium-containing molten iron, the contents of C, V, Mn, S, P, Si, Ti, and Fe in weight percent are shown in Table 1. Table 2 shows the contents of C, V, Mn, S, P, Si, Ti, and Fe in weight percent in the obtained molten iron after desulfurization.

[0037] (2) add the molten iron after the desulfurization of 140t in Panzhihua Iron and Steel's 120t compound blowing vanadium converter, add the sodium salt of 1.5t (the NaCO that contains 86.8% by weight 3 ), and use a 339 ...

Embodiment 2

[0043] In this example, 27CrMoNbV low-phosphorus-sulfur pipeline steel was smelted.

[0044] (1) Carry out compound injection deep desulfurization with vanadium-containing molten iron as raw material, its injection time is 34.6 minutes, relative to 1 ton of vanadium-containing molten iron, use 5.2 kilograms of passivated lime powder (the content of CaO is 93.2% by weight), 1.11 kg of passivated magnesium powder (the metal Mg content is 93.4% by weight) to obtain desulfurized molten iron. In vanadium-containing molten iron, the contents of C, V, Mn, S, P, Si, Ti, and Fe in weight percent are shown in Table 1. Table 2 shows the contents of C, V, Mn, S, P, Si, Ti, and Fe in weight percent in the obtained molten iron after desulfurization.

[0045] (2) Add 140t of molten iron after desulfurization in Panzhihua Iron and Steel 120t re-blowing vanadium converter, add 3.2t of sodium salt (containing 86.8% by weight of NaCO 3 ), and use a 339 oxygen lance for oxygen blowing and depho...

Embodiment 3

[0051] What this embodiment smelts is P72LX cord steel.

[0052] (1) Carry out compound injection deep desulfurization with vanadium-containing molten iron as raw material, its injection time is 24.2 minutes, with respect to 1 ton of vanadium-containing molten iron, use 4.7 kilograms of passivated lime powder (the content of CaO is 93.2% by weight), 1.03 kg of passivated magnesium powder (the metal Mg content is 93.4% by weight) to obtain desulfurized molten iron. In vanadium-containing molten iron, the contents of C, V, Mn, S, P, Si, Ti, and Fe in weight percent are shown in Table 1. Table 2 shows the contents of C, V, Mn, S, P, Si, Ti, and Fe in weight percent in the obtained molten iron after desulfurization.

[0053] (2) Add 140t of molten iron after desulfurization in Panzhihua Iron and Steel 120t re-blown vanadium converter, add 2.8t of sodium salt (containing 86.8% by weight of NaCO 3 ), and use a 339 oxygen lance for oxygen blowing and dephosphorization, and add 1t o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com