Metal matrix based niobium carbide rare earth ceramic composite material and method

A ceramic composite material, niobium carbide rare earth technology, applied in the field of rare earth ceramic composite material, niobium carbide rare earth ceramic composite material, can solve the problems of complex production process, narrow application range, long processing cycle, etc. Short cycle time, the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

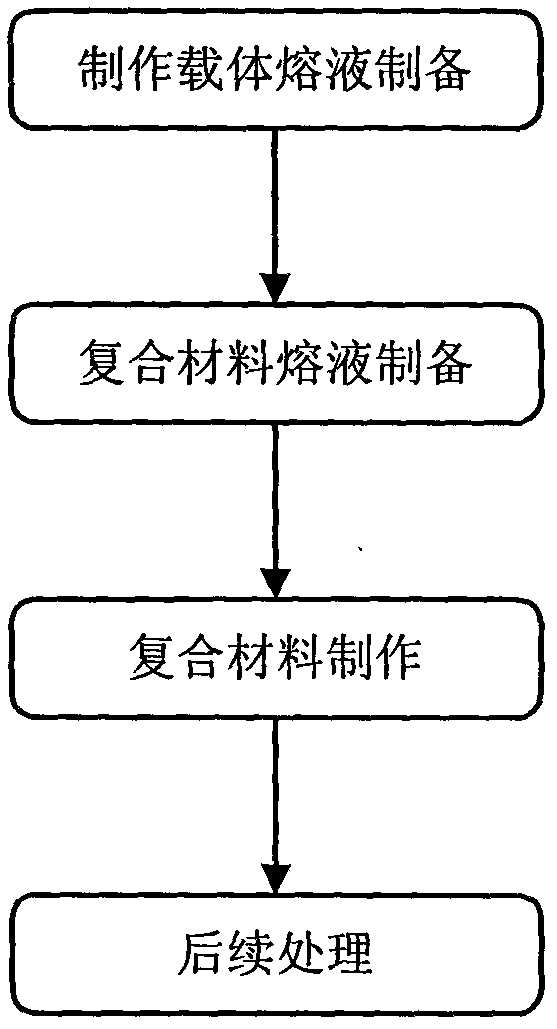

Image

Examples

Embodiment 1

[0014] A niobium carbide rare earth ceramic composite material made on the surface of a metal workpiece is a multi-element multi-phase ceramic crystal with a structure of NbC-V-RE-Fe-C, wherein NbC is a niobium carbide compound, V is a metal vanadium element, and RE is Rare earth element, Fe is metal iron element, and C is carbon element. Its cross-sectional shape combined with the surface of the metal workpiece is a kind of irregular sawtooth interlocking shape, and completely covers the surface of the metal workpiece with a certain thickness.

[0015] In the above-mentioned niobium carbide rare earth ceramic composite material produced on the surface of the metal workpiece, the metal workpiece is a heat-treated steel plate stamping die, the material is Cr12Mo1V, the stamping plate is thicker ≈ 3.5mm, and the plate is 590MPa high. tension steel plate.

[0016] The preparation method of the niobium carbide rare earth ceramic composite material made on the metal workpiece surfa...

Embodiment 2

[0022] A niobium carbide rare earth ceramic composite material made on the surface of a metal workpiece is a multi-element multi-phase ceramic crystal with a structure of NbC-V-RE-Fe-C, wherein NbC is a niobium carbide compound, V is a metal vanadium element, and RE is Rare earth element, Fe is metal iron element, and C is carbon element. Its cross-sectional shape combined with the surface of the metal workpiece is a kind of irregular sawtooth interlocking shape, and completely covers the surface of the metal workpiece with a certain thickness.

[0023] In the above-mentioned niobium carbide rare earth ceramic composite material made on the surface of the metal workpiece, the metal workpiece is a heat-treated die-casting pin part of an automobile engine cylinder, and its material is 4Cr5MoSiV1, which is called a die-casting pin part here.

[0024] The preparation method of the niobium carbide rare earth ceramic composite material made on the metal workpiece surface of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com