Batch sample experimental device

An experimental device and sample technology, which is applied in the field of batch sample experimental devices, can solve the problems of inability to measure signal transmission, small number of samples, scratches, etc., and achieve the effects of strong scalability, simple structure, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

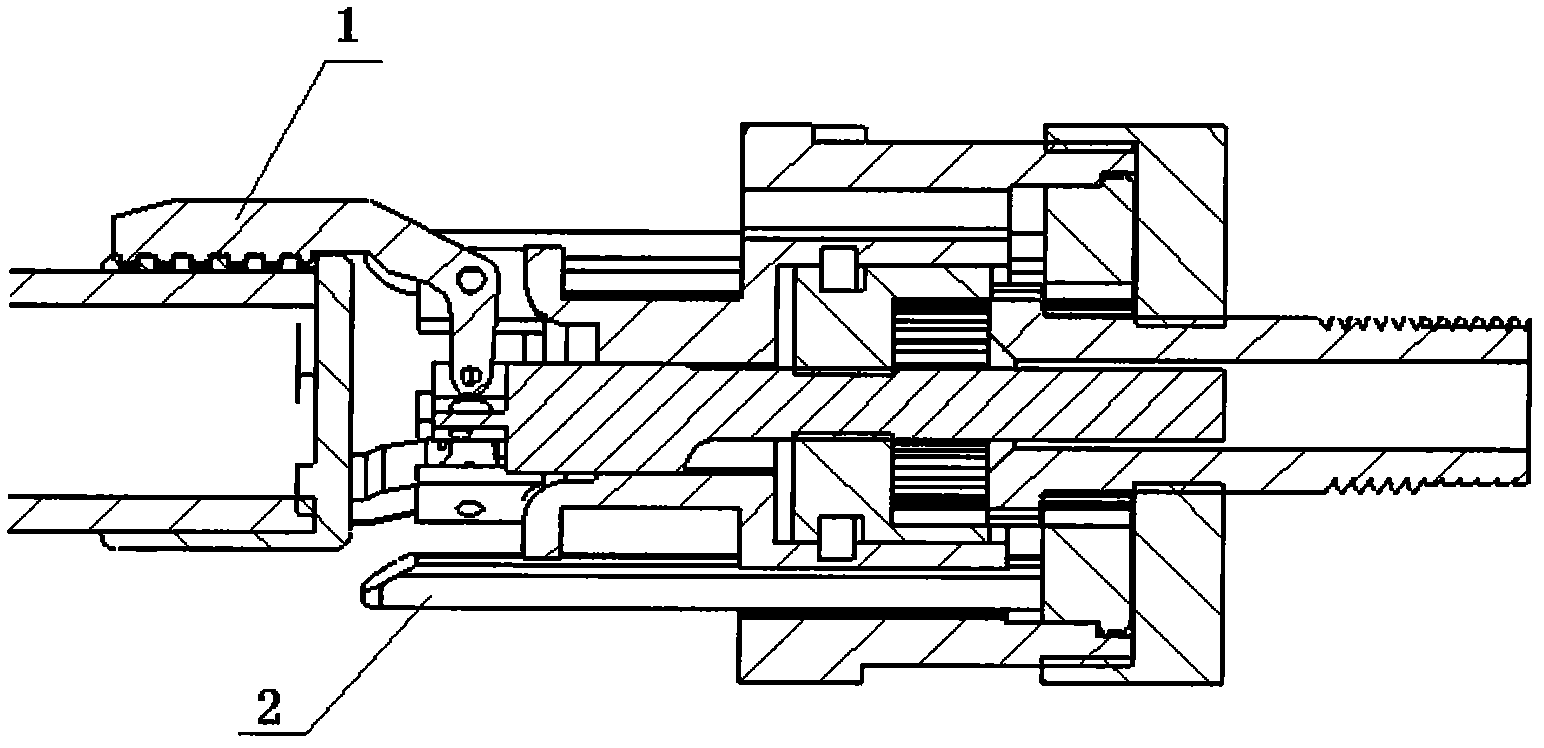

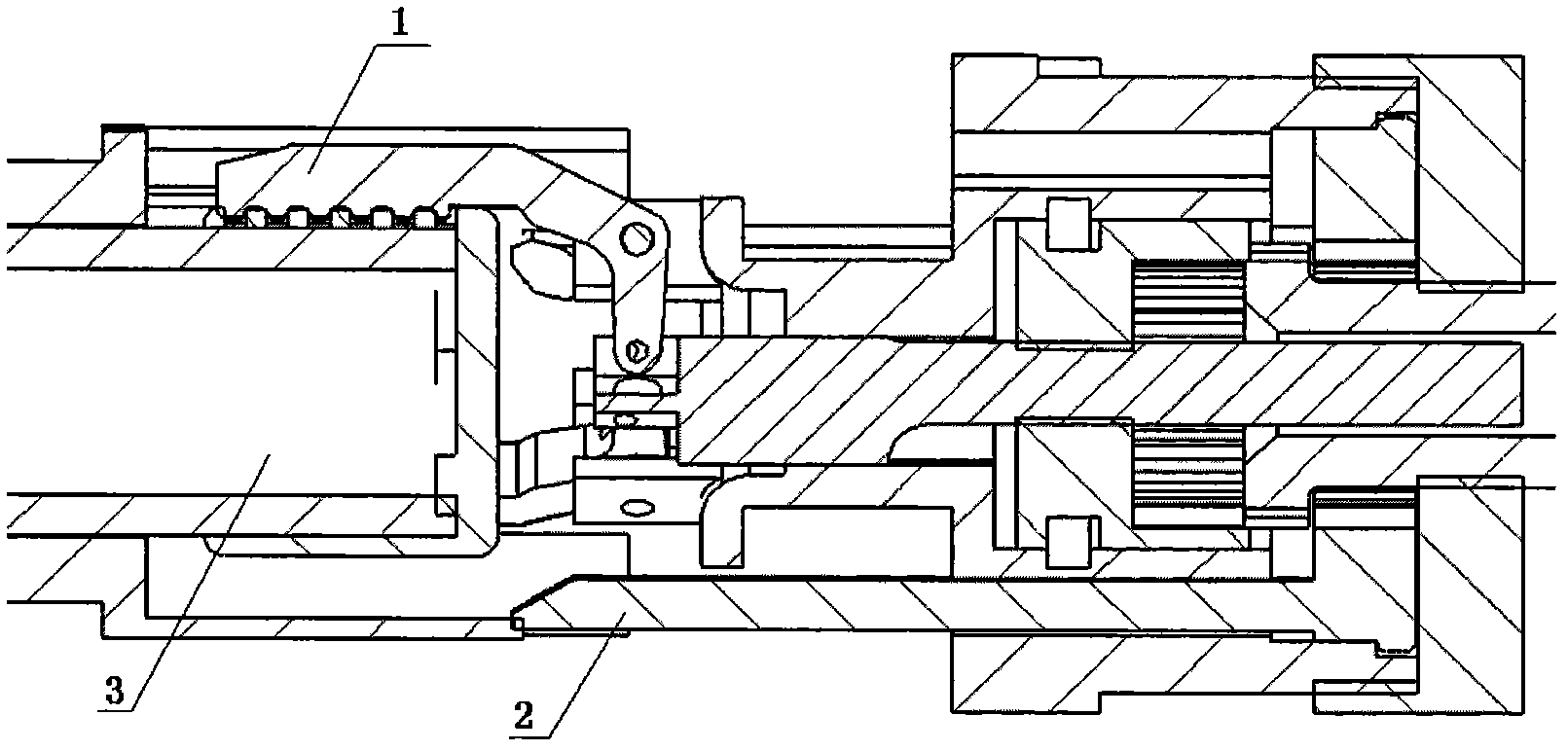

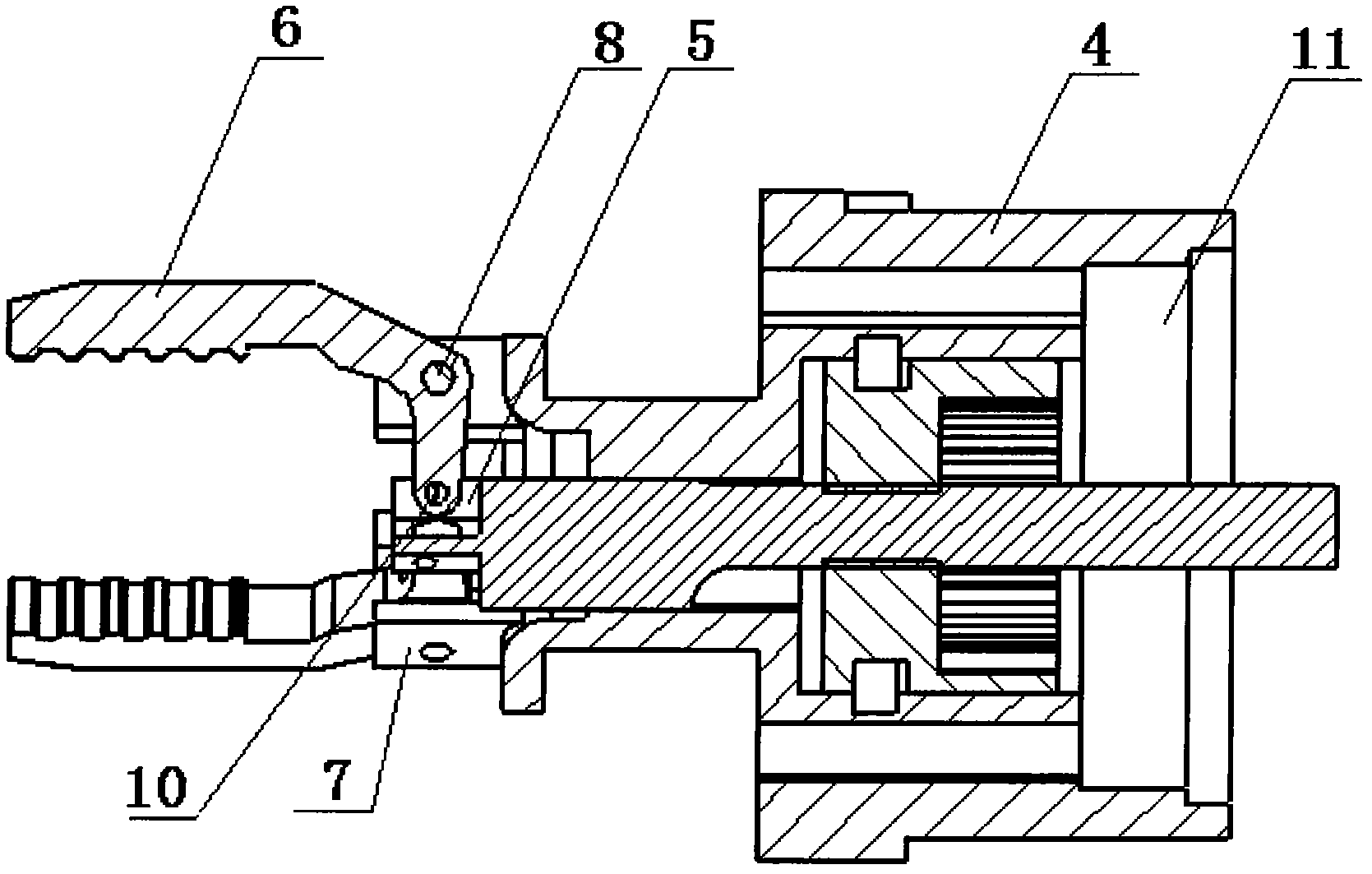

[0071] Such as image 3 As shown, the batch sample experimental device is composed of a sample chamber 28, a sample storehouse 29, a heating furnace 30, a manipulator 33, a vertical support 31 for the hand body, a horizontal screw 32, and a sample locking mechanism. When the experimental device is working, the manipulator 33 runs vertically to the vertical position of the sample ampoule 3 to be taken, and then moves horizontally to the position of the sample to be taken. The sample library 29 is valid forward to the limit switch. The manipulator 33 is closed to grab the sample ampoule 3, the manipulator 33 rotates clockwise to unlock the space between the sample ampoule 3 and the sample chamber 28, the sample storehouse 29 moves to the bottom, and the sample ampoule 3 is taken out. Manipulator 33 runs vertically earlier, and then runs horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com