Plastic liquid crystal film and making method thereof

A manufacturing method and liquid crystal film technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems affecting the life and use effect of plastic liquid crystal films, erosion and damage of conductive layers, and uncontrollable gray scale, etc., to achieve enhanced Effects of bonding, fast response, improved optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

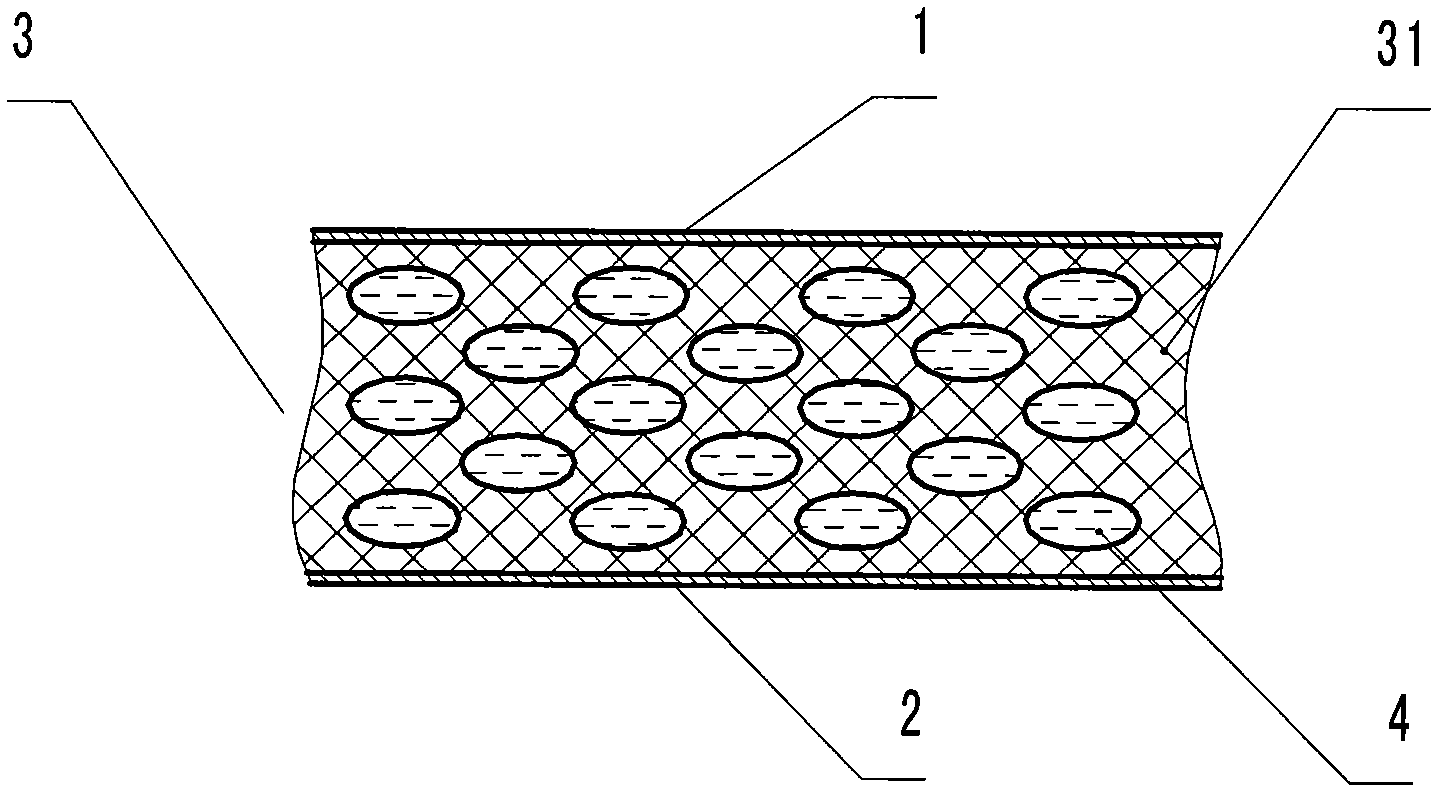

[0026] see figure 1 ( figure 1 is a cross-sectional enlarged view of the plastic liquid crystal film), the plastic liquid crystal film of the present invention includes a liquid crystal-plastic core layer 3 and two parallel and symmetrically arranged transparent conductive films 1,2, and the liquid crystal-plastic core layer is sandwiched Between the two transparent conductive films, the liquid crystal-plastic core layer includes a high molecular polymer matrix 31, and liquid crystal material microspheres 4 are uniformly distributed in the high molecular polymer matrix, and the high molecular polymer matrix The refractive index matches the ordinary light refractive index of the liquid crystal material; the liquid crystal molecular director in the liquid crystal material microsphere is approximately parallel to the two transparent conductive films; electrodes are arranged on the transparent conductive film. The plastic liquid crystal film of the present invention is also calle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com