Photovoltaic cell

A photovoltaic cell and battery technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as difficulty in accurately controlling the thickness of the n-type doped layer, improve open circuit voltage and overall efficiency, reduce doping concentration, and improve compounding. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

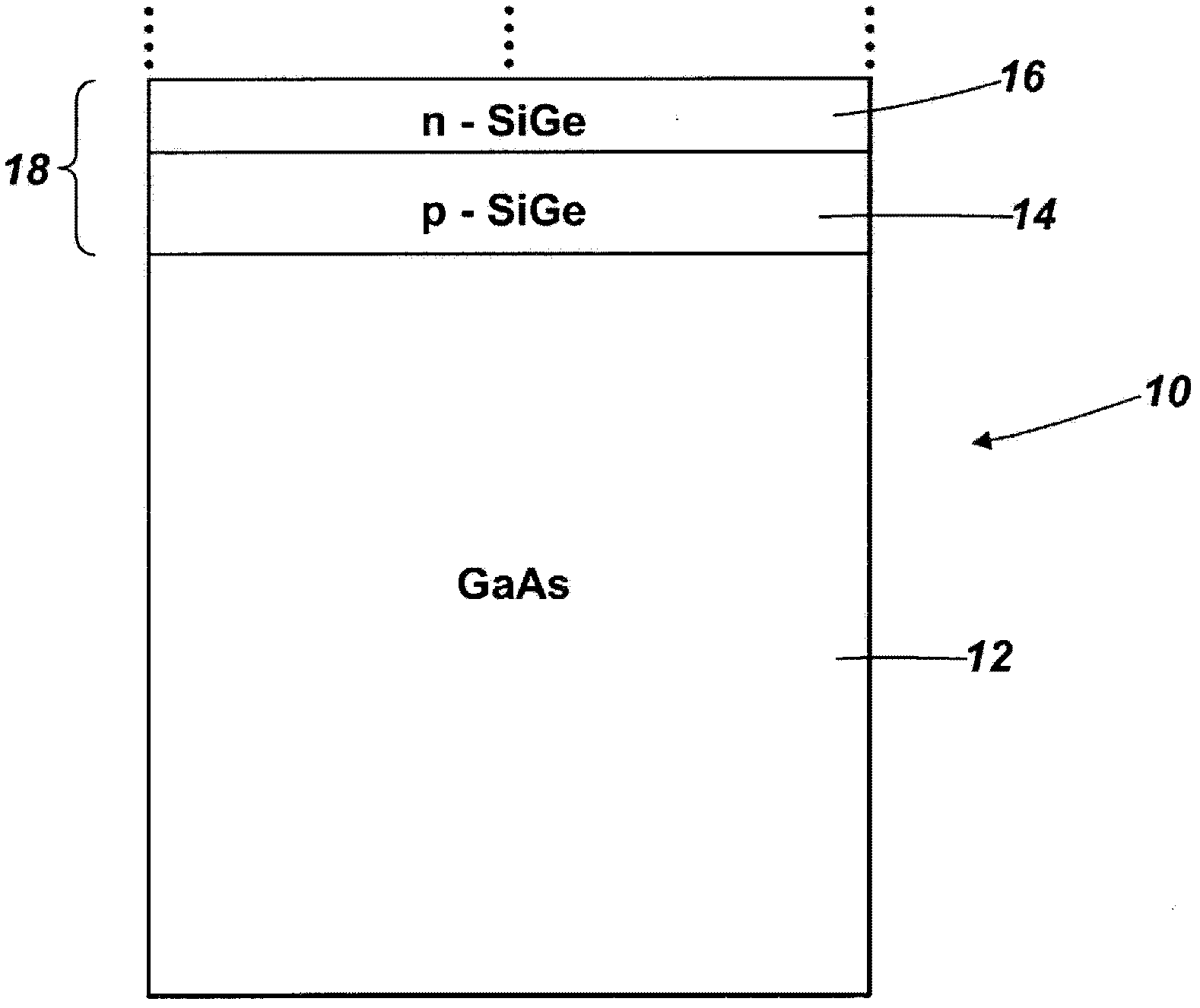

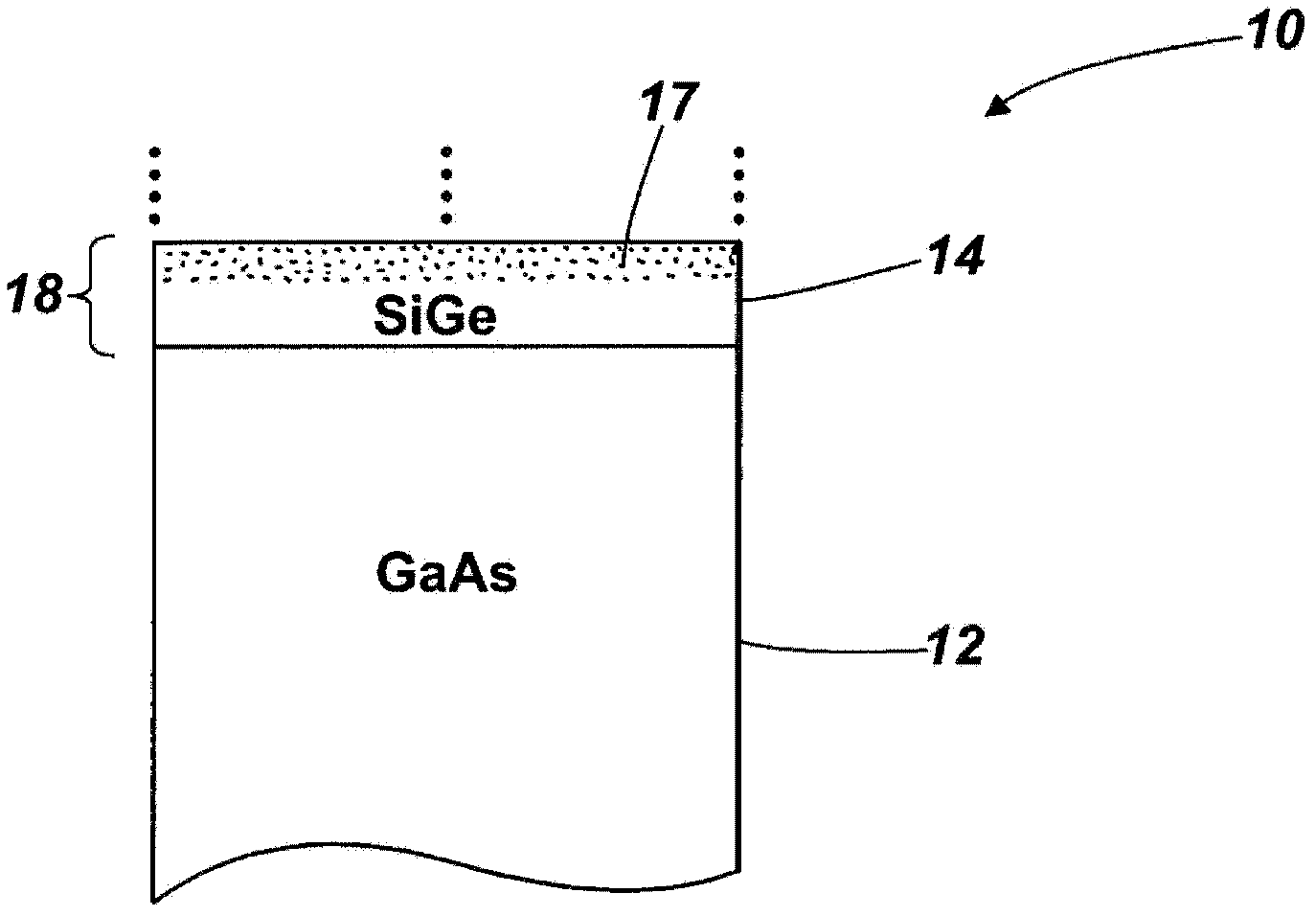

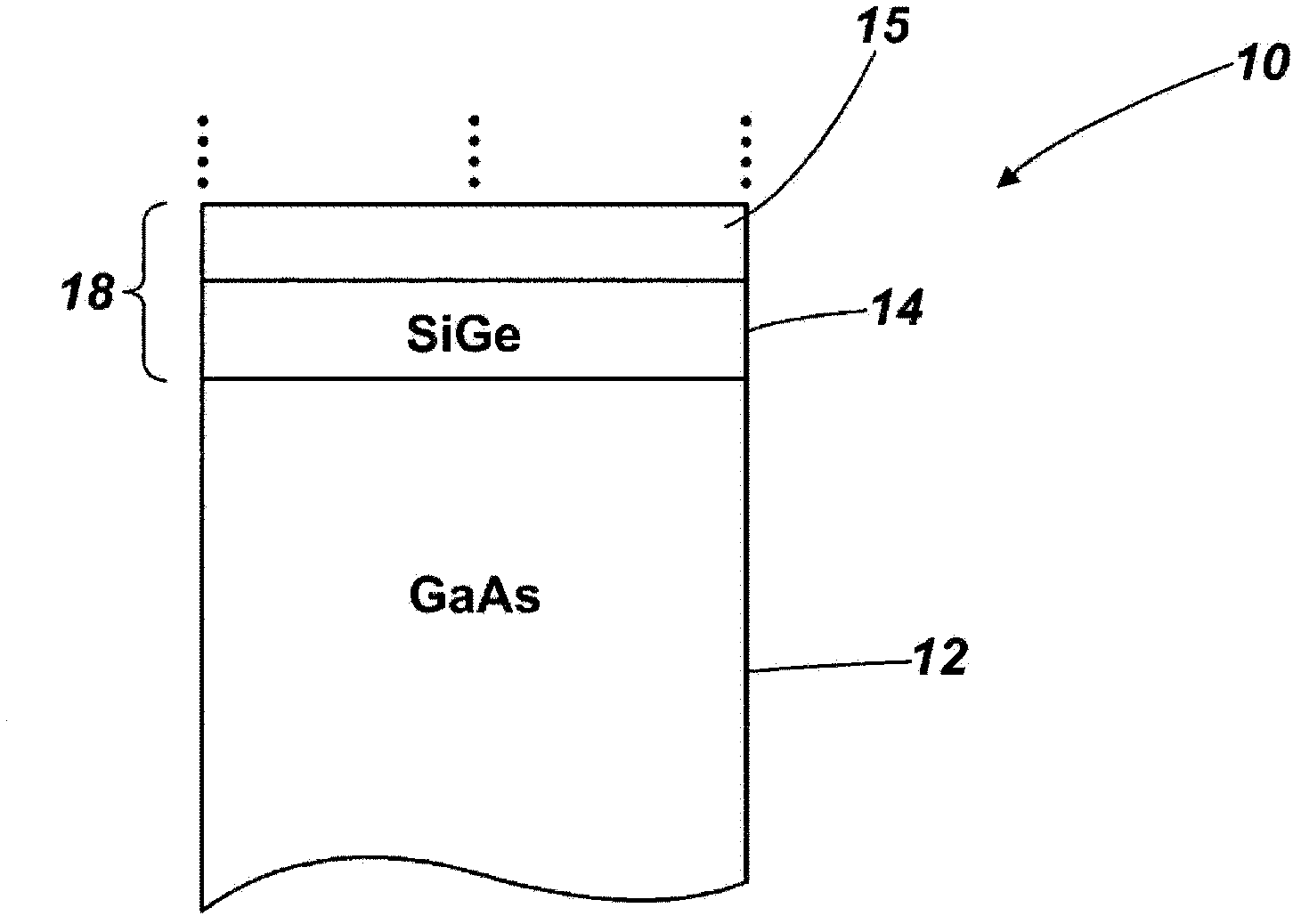

[0033] see Figure 1A , which schematically shows the photovoltaic cell structure 10 according to the first embodiment of the present invention. The structure 10 includes a GaAs substrate 12 . On said GaAs substrate there are two continuous first layers 14 , 16 of SiGe material epitaxially grown on the GaAs substrate and monolithic therewith, these layers together forming a first germanium-based photovoltaic junction 18 . The silicon content of the first layer of SiGe is chosen to substantially lattice match the GaAs substrate. For this reason, Si x Ge 1-x The silicon fraction x may be 0-0.04, more preferably 0.01-0.03, still more preferably 0.016-0.02. To form a practical photovoltaic junction, the lower SiGe layer can typically be doped p-type to a concentration of about 5×10 16 cm -3 ~5×10 19 cm -3 , and the thickness is about 1 μm to 2 μm. The upper SiGe layer can typically be n-type doped to a concentration of about 1 x 10 17 cm -3 , and the thickness is about 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com